Tempered film and preparation method thereof

A tempered film and tempered technology, used in branch equipment, film/sheet adhesives, telephone communications, etc., can solve the problems of difficulty in protecting mobile phone screens, poor impact resistance, and low structural strength, and achieve a good structure. Strength and wear resistance, improve bond strength, improve the effect of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

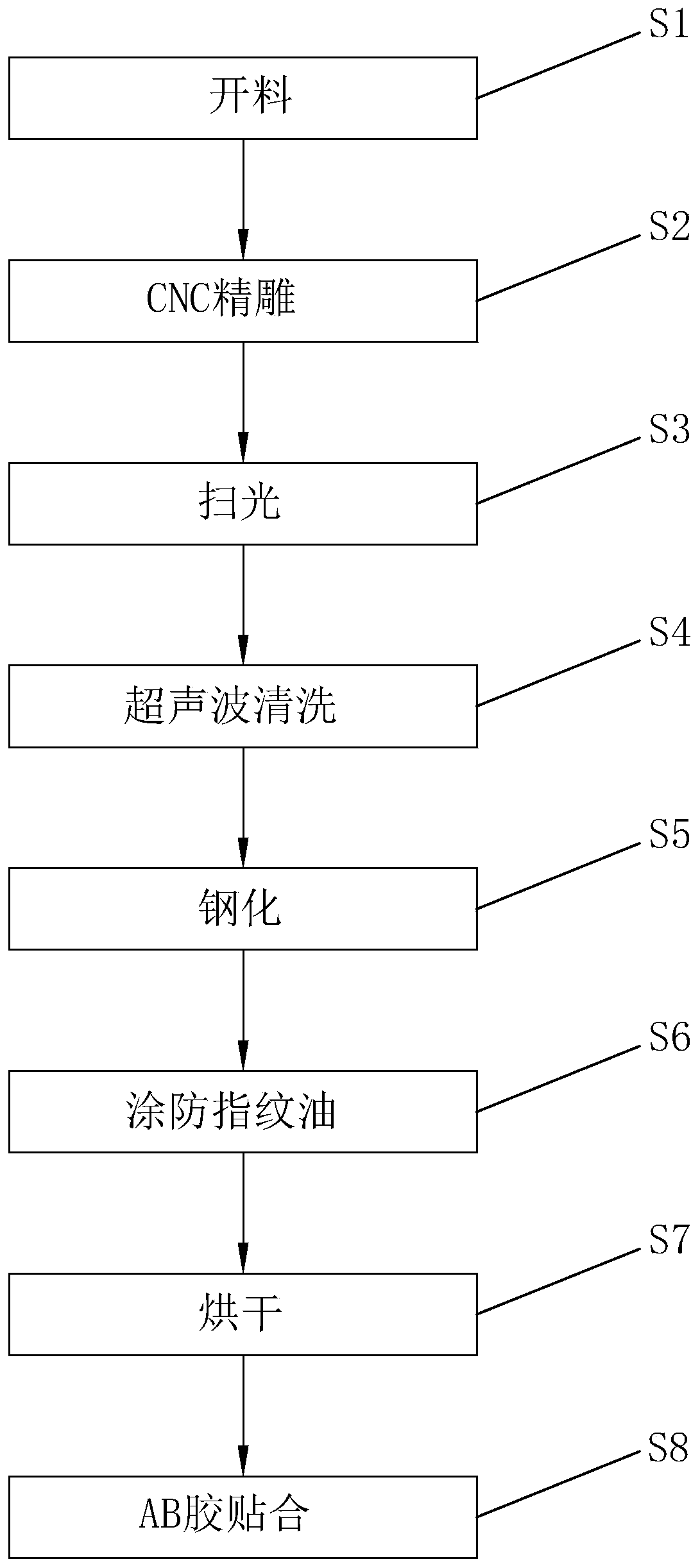

[0041] A method for preparing a tempered film, comprising the steps of:

[0042] S1. Use a cutting machine to cut the glass substrate: before cutting, use clean white paper to pad the cutting platform of the cutting machine, and place the glass substrate on the white paper to avoid the glass substrate during the cutting process. The impurities on the cutting machine are attached in the middle, and then the glass substrate is cut into the required shape and size by the cutting machine to obtain the glass substrate. The thickness range of the glass substrate is 0.15mm.

[0043] S2. CNC engraving: CNC machine tools are used to carve holes corresponding to the model on the glass substrate after cutting.

[0044] S3. Light sweeping: polish the edge of the glass substrate to make it into a certain arc, and the light sweeping time is 4 minutes.

[0045] S4. Ultrasonic cleaning: In the dust-free workshop, put the glass substrate in an ultrasonic cleaning machine for three cleanings, ...

Embodiment 2

[0056] A kind of preparation method of toughened film, the difference with embodiment 1 is: comprise the following steps:

[0057] S1. Use a cutting machine to cut the glass substrate: before cutting, use clean white paper to pad the cutting platform of the cutting machine, and place the glass substrate on the white paper to avoid the glass substrate during the cutting process. The impurities on the cutting machine are attached in the middle, and then the glass substrate is cut into the required shape and size by the cutting machine to obtain the glass substrate. The thickness of the glass substrate is 0.2mm.

[0058] S2. CNC engraving: CNC machine tools are used to carve holes corresponding to the model on the glass substrate after cutting.

[0059] S3. Light sweeping: polish the edge of the glass substrate to make it into a certain arc, and the light sweeping time is 5 minutes.

[0060] S4. Ultrasonic cleaning: In the dust-free workshop, put the glass substrate in an ultras...

Embodiment 3

[0071] A kind of preparation method of toughened film, the difference with embodiment 1 is: comprise the following steps:

[0072] S1. Use a cutting machine to cut the glass substrate: before cutting, use clean white paper to pad the cutting platform of the cutting machine, and place the glass substrate on the white paper to avoid the glass substrate during the cutting process. The impurities on the cutting machine are attached in the middle, and then the glass substrate is cut into the required shape and size by the cutting machine to obtain the glass substrate. The thickness of the glass substrate is 0.22mm.

[0073] S2. CNC engraving: CNC machine tools are used to carve holes corresponding to the model on the glass substrate after cutting.

[0074] S3. Light sweeping: polish the edge of the glass substrate to make it into a certain arc, and the sweeping time is 6 minutes.

[0075] S4. Ultrasonic cleaning: In the dust-free workshop, put the glass substrate in an ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com