Single-side mounting structure of assembly type window sleeve

An installation structure and assembly technology, which is applied in the field of window covers, can solve the problems of poor weather resistance, increased construction costs, and low installation error tolerance, and achieve the effects of low installation and operation strength, saving construction costs, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

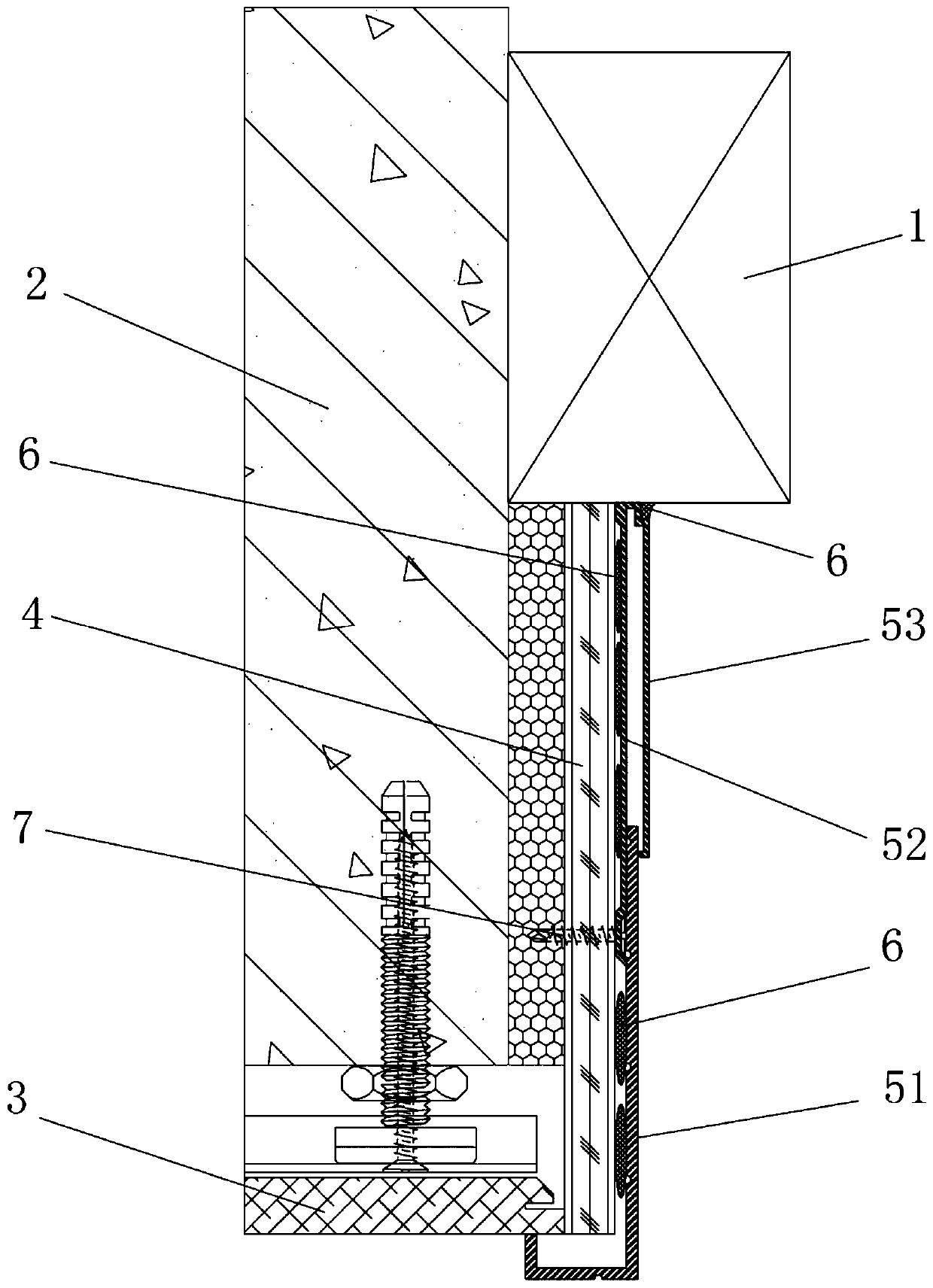

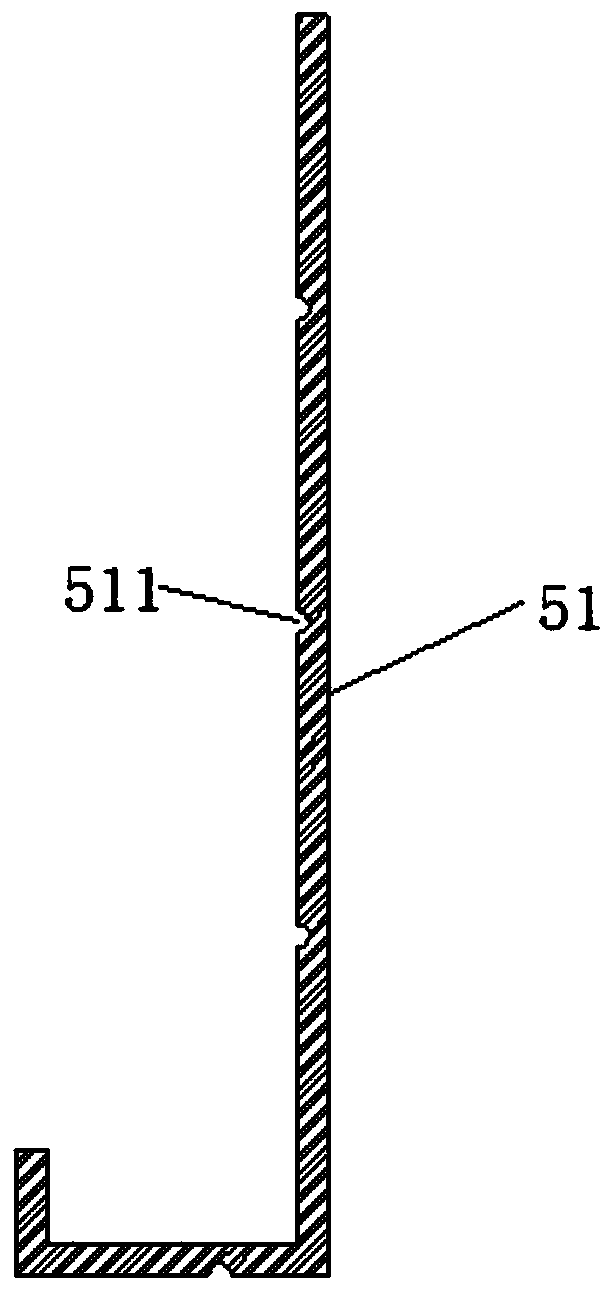

[0035] see Figure 1 to Figure 4 , the figure shows a unilateral installation structure of a prefabricated window cover provided by Embodiment 1 of the present invention, including: a window frame 1, which is connected to a wall 2; a decorative panel 3, which is arranged on the inner side of the wall 2; The base plate 4 is located on the indoor side of the window frame 1 and is connected to the wall 2; the aluminum alloy window cover assembly is located on the indoor side of the window frame 1, and the aluminum alloy window cover assembly includes a connection kit and a plug plate 51, and the The top is connected to the window frame 1, and the connecting kit includes a fixing plate 52 and a connecting plate 53. The fixing plate 53 is connected to one end of the connecting plate 53. The fixing plate 52 is fixedly connected to the base plate 4. One end of the plug-in plate 51 is inserted into the fixing plate 52 and the connecting plate 53. Between the connecting plates 53 , the...

Embodiment 2

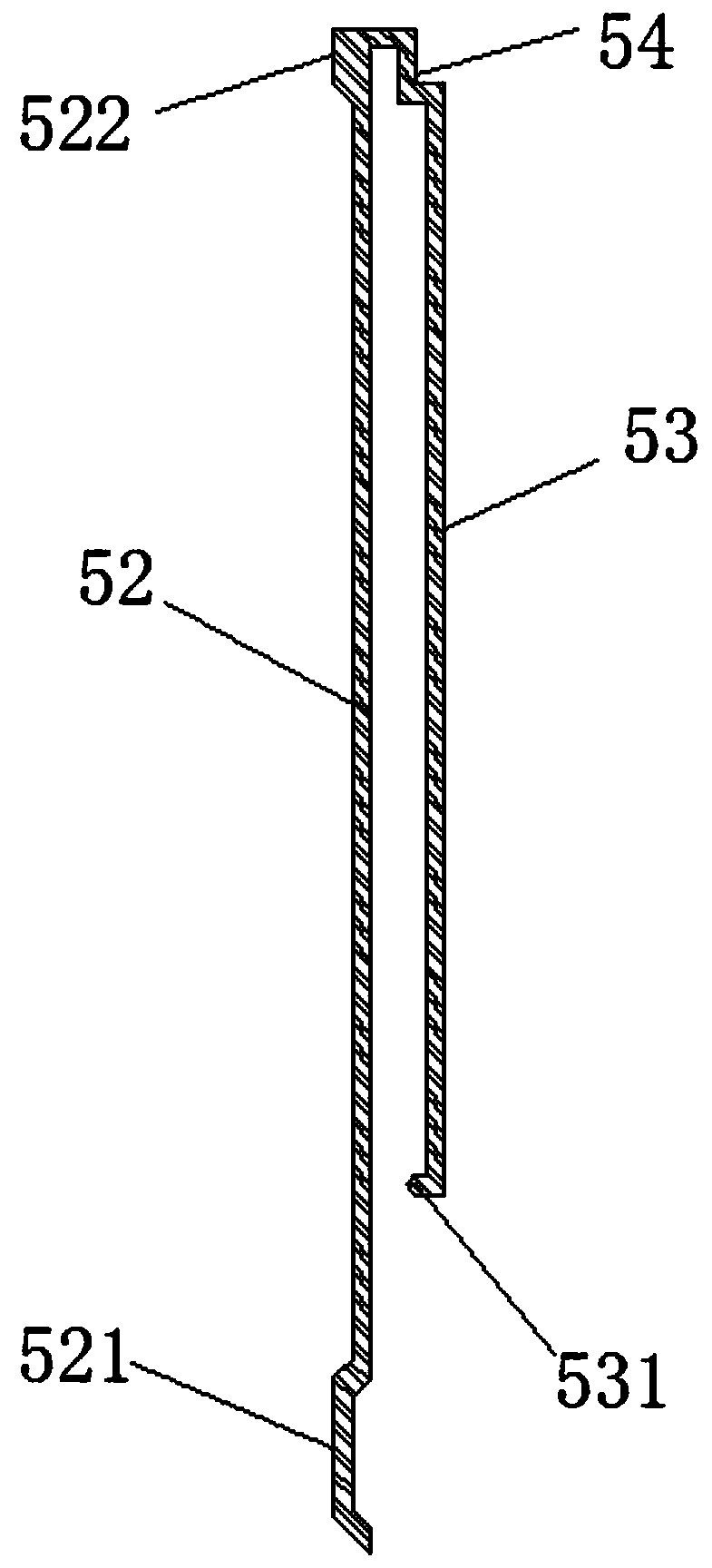

[0045] see Figure 1 to Figure 4 , the figure shows a unilateral installation structure of a prefabricated window cover provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: fixing Both ends of the plate 52 are respectively provided with a fixing part 521 and a positioning part 522, and the fixing part 521 and the positioning part 522 are all located on the outside of the fixing plate 52; The boss and the fixing portion 521 are nail sinking slots; the inner side of the insertion plate 51 is provided with a plurality of locking slots 511 , and the outer edges of the nail sinking slots are engaged with the locking slots 511 . Through the setting of the above structure, due to the setting of the fixing part 521 and the positioning part 522, the middle position of the fixing plate 52 is lower than its two ends, so there is a gap to apply MS structural glue...

Embodiment 3

[0047] see Figure 1 to Figure 3 , the figure shows a unilateral installation structure of a prefabricated window cover provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: fixing The plate 52 is parallel to the connecting plate 53; the bottom of the connecting plate 53 is provided with a connecting hook 531 bent toward the fixed plate 52; the distance between the connecting hook 531 and the fixing plate 52 is consistent with the thickness of the inserting plate 51; The free end is "U" shaped. Through the setting of the above structure, the length of the inserting plate 51 can be arbitrarily adjusted in the fixing plate 52 and the connecting plate 53, see Figure 4-5 , respectively corresponding to the shortest installation distance and the longest installation distance of the aluminum alloy window cover, which can be adjusted according to actual needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com