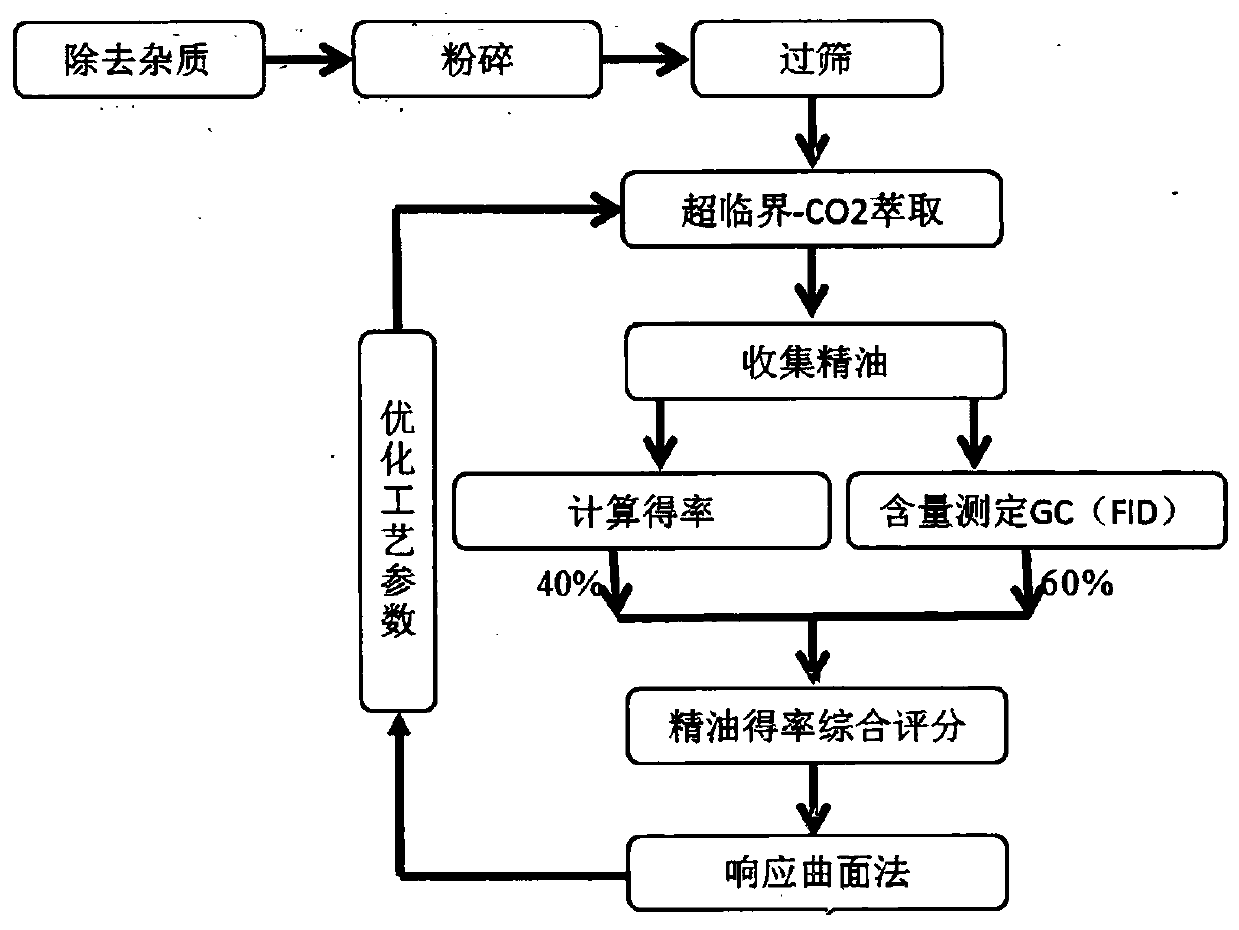

Method for optimizing supercritical extraction of high-purity fennel essential oil based on response surface method

A response surface method and supercritical technology, applied in the direction of fat oil/fat production, measuring devices, instruments, etc., can solve problems affecting the quality of essential oils, poor extraction process parameters, etc., achieve short extraction time, no solvent residue, and increase production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Supercritical Extraction of Cumin Essential Oil:

[0039] a. take cumin seeds and pulverize, after sieving with a particle size of 18 mesh sieves, seal and preserve;

[0040] b. Use Design Expert 8.0.6 software to carry out Box-Behnken design, obtain the extraction temperature of 30°C, the extraction pressure of 100 bar, and the extraction time of 30 minutes. Put 50 g of the material obtained in step a into the extraction kettle of the supercritical carbon dioxide extraction device at one time. Medium, crushing particle size 18 mesh, CO 2 Under the condition of flow rate 2L / min, the mass ratio of cumin essential oil is 3%;

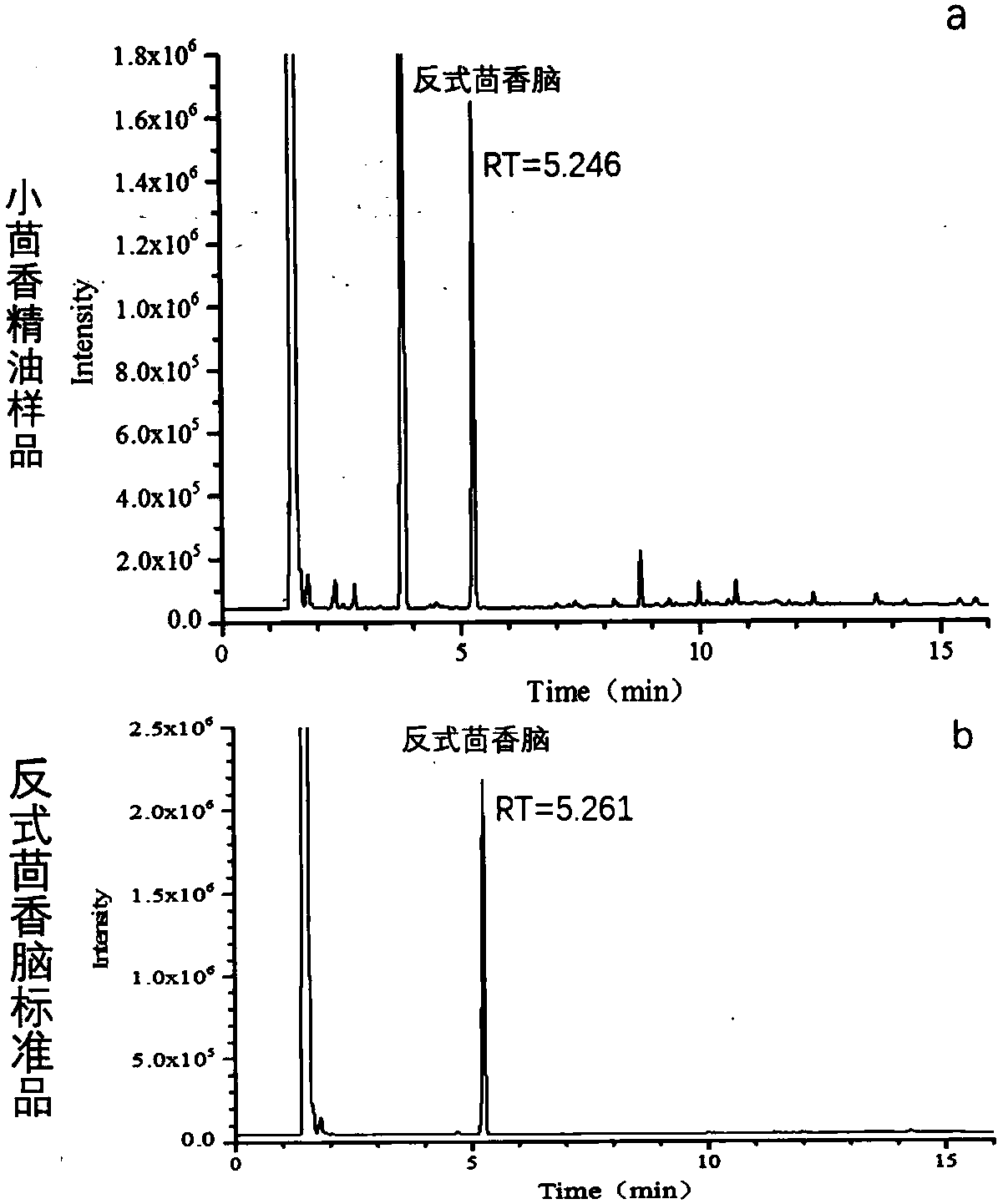

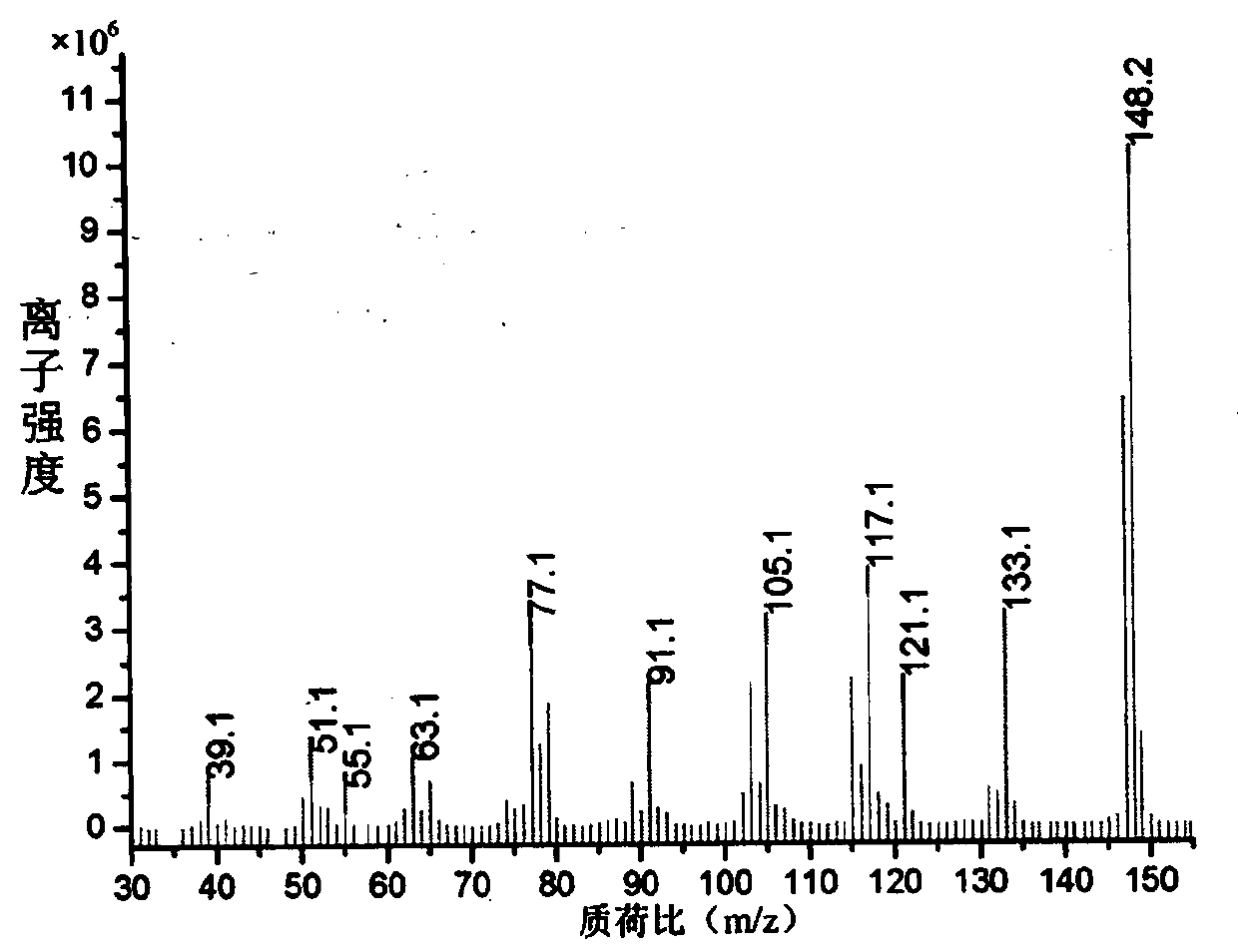

[0041] Determination of the purity of trans-anethole in cumin essential oil:

[0042] c. Determination of the content of trans-anethole in the essential oil by gas chromatography external standard method: first prepare the mother solution of trans-anethole with a concentration of 400 μg / ml, then dissolve it with ethyl acetate and dilute it to a co...

Embodiment 2

[0045] Supercritical Extraction of Cumin Essential Oil:

[0046] a. take cumin seeds and pulverize, after sieving with a particle size of 30 mesh sieves, seal and preserve;

[0047] b. Use Design Expert 8.0.6 software to carry out Box-Behnken design, obtain the extraction temperature of 40°C, the extraction pressure of 200bar, and the extraction time of 70min. Put the material obtained in step a into the extraction kettle of the supercritical carbon dioxide extraction device at a time of 100g Medium, crushing particle size 30 mesh, CO 2 Under the condition of flow rate 6L / min, the mass ratio of cumin essential oil is 4%;

[0048] Determination of the purity of trans-anethole in cumin essential oil:

[0049] c. Determination of the content of trans-anethole in the essential oil by gas chromatography external standard method: first prepare the mother solution of trans-anethole with a concentration of 400 μg / ml, then dissolve it with ethyl acetate and dilute it to a concentrati...

Embodiment 3

[0052] Supercritical Extraction of Cumin Essential Oil:

[0053] a. take cumin seeds and pulverize, after sieving with a particle size of 40 mesh sieves, seal and preserve;

[0054] b. Use the Design Expert 8.0.6 software to carry out Box-Behnken design, obtain the extraction temperature of 45°C, the extraction pressure of 300bar, and the extraction time of 120min. Put the material obtained in step a into the extraction kettle of the supercritical carbon dioxide extraction device at a time of 120g Medium, crushing particle size 40 mesh, CO 2 Under the condition of a flow rate of 8L / min, the mass ratio of cumin essential oil is 5%;

[0055] Determination of the purity of trans-anethole in cumin essential oil:

[0056] c. Determination of the content of trans-anethole in the essential oil by gas chromatography external standard method: first prepare the mother solution of trans-anethole with a concentration of 400 μg / ml, then dissolve it with ethyl acetate and dilute it to a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com