Underground coal mine short-distance multi-purpose special hoisting vehicle device

A short-distance, multi-purpose technology, used in cranes, transportation and packaging, load hanging components, etc., can solve the problems of high labor intensity, high safety risks, and long construction periods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

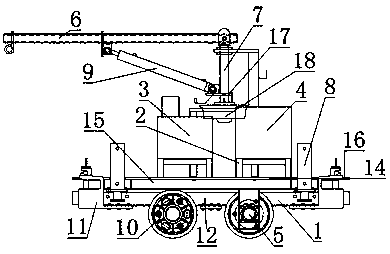

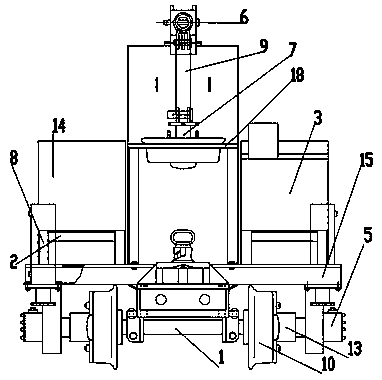

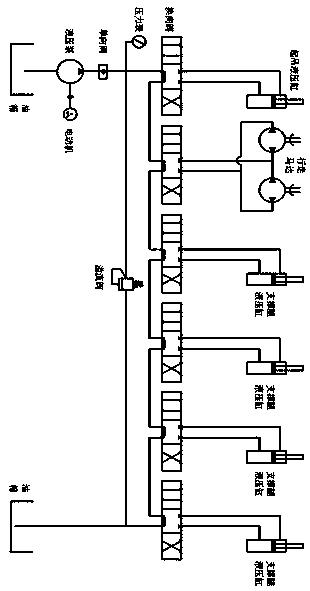

[0020] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a short-distance multi-purpose lifting special vehicle device for underground coal mines includes a mine car chassis 1, an equipment placement frame 2, a hydraulic station 3, a magnetic starter 4, a travel motor 5, a lifting arm 6, a rotating shaft 7, and a hydraulic support leg Cylinder 8, lifting hydraulic cylinder 9, two sets of wheelsets 10, two bumpers 11, complete chassis 12, channel steel 14, transition frame body 15, steel plate 16, connecting plate 17, base 18, equipment placement frame 2 and mine car chassis 1 is connected and fixed by bolts, three equipment racks 2 are independently connected and installed with hydraulic station 3, magnetic starter 4 and toolbox, hydraulic station 3 is connected to magnetic starter 4 with cables, and magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com