Aluminum-manganese material formed through high temperature brazing and forming method thereof

An aluminum-manganese alloy and brazing technology, applied in the field of aluminum-manganese materials, can solve the problems of low machining efficiency, easy softening or melting, and high production cost of aluminum alloys, and achieve low cost, high production efficiency, and excellent high-temperature brazing properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An aluminum-manganese alloy that can be brazed at high temperature, using a semi-solid vacuum slow-shot die-casting method to prepare a power battery shell cavity (maximum external dimension 410mm), including the following steps:

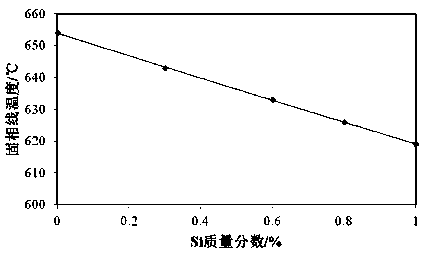

[0021] (1) Material preparation: According to the composition control standard (mass fraction) "Fe: 0.6%, Si: 0.8%, Mn: 1.6%, Zn: 0.08%, Ti: 0.1%, Al balance" for material preparation. Aluminum-iron master alloy, pure silicon, aluminum-manganese master alloy, aluminum-titanium master alloy, high-purity aluminum and pure zinc are selected as raw materials.

[0022] (2) All furnace materials need to be cleaned on the surface, free of dust and oil; they need to be baked at a temperature of about 150°C for 1 to 2 hours.

[0023] (3) Melting: Melt high-purity aluminum charge in a graphite crucible, control the temperature of aluminum water at 730~750°C, and then add aluminum-iron master alloy, pure silicon, aluminum-manganese master alloy, aluminu...

Embodiment 2

[0029] An aluminum-manganese alloy that can be brazed at high temperature, using a liquid squeeze casting method to prepare a power battery cavity connector (maximum external dimension 80mm), including the following steps:

[0030] (1) Material preparation: According to the composition control standard (mass fraction) "Fe: 0.8%, Si: 0.3%, Mn: 1.5%, Zn: 0.08%, Ti: 0.1%, Al balance" for material preparation. Aluminum-iron master alloy, pure silicon, aluminum-manganese master alloy, aluminum-titanium master alloy, high-purity aluminum and pure zinc are selected as raw materials.

[0031] (2) All furnace materials need to be cleaned on the surface, free of dust and oil; they need to be baked at a temperature of about 150°C for 1 to 2 hours.

[0032] (3) Melting: Melt high-purity aluminum charge in a graphite crucible, control the temperature of aluminum water at 740~750°C, and then add aluminum-iron master alloy, pure silicon, aluminum-manganese master alloy, aluminum-titanium mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com