Preparation method of nano CeO2 reinforced NiCoCrAlY coating

A kind of coating and nanotechnology, applied in the field of new material preparation, can solve the problems of poor wear resistance, easy oxidation, limited use, etc., achieve excellent anti-friction and anti-wear performance, and improve the effect of friction and wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] (1) After the substrate is ground, polished and sandblasted, it is cleaned with ethanol for use.

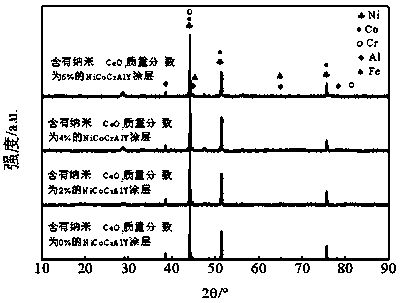

[0018] (2) figure 1 For the nano-CeO used 2 Enhanced NiCoCrAlY powder XRD phase. The powder is mainly composed of Ni, Co, Cr and Al, the content of Y is low, and no obvious peak is found.

[0019] (3) figure 2 For the prepared nano-CeO 2 Enhanced surface morphology of NiCoCrAlY coating. When nano-CeO 2 When the mass fraction was 2%, the dendrites on the coating surface increased, and a small amount of cellular crystals were dispersed around the dendrites. When nano-CeO 2 When the mass fraction is 4%, the surface of the coating is covered with coarse dendrites, the cellular crystals basically disappear, and the surface grains are coarsened. When nano-CeO 2 When the mass fraction was 6%, the coarse dendrites on the coating surface were broken, and the cellular crystals increased, mainly short dendrites and cellular crystals.

[0020] (4) image 3 For the prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com