White eliminating device without additional power for continuous row expansion container

A technology of expanding container and continuous row is applied in the field of whitening device without external power, which can solve the problems of energy waste, deterioration of urban landscape, waste of water resources, etc., and achieve the effects of high heat exchange efficiency, high ventilation efficiency and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

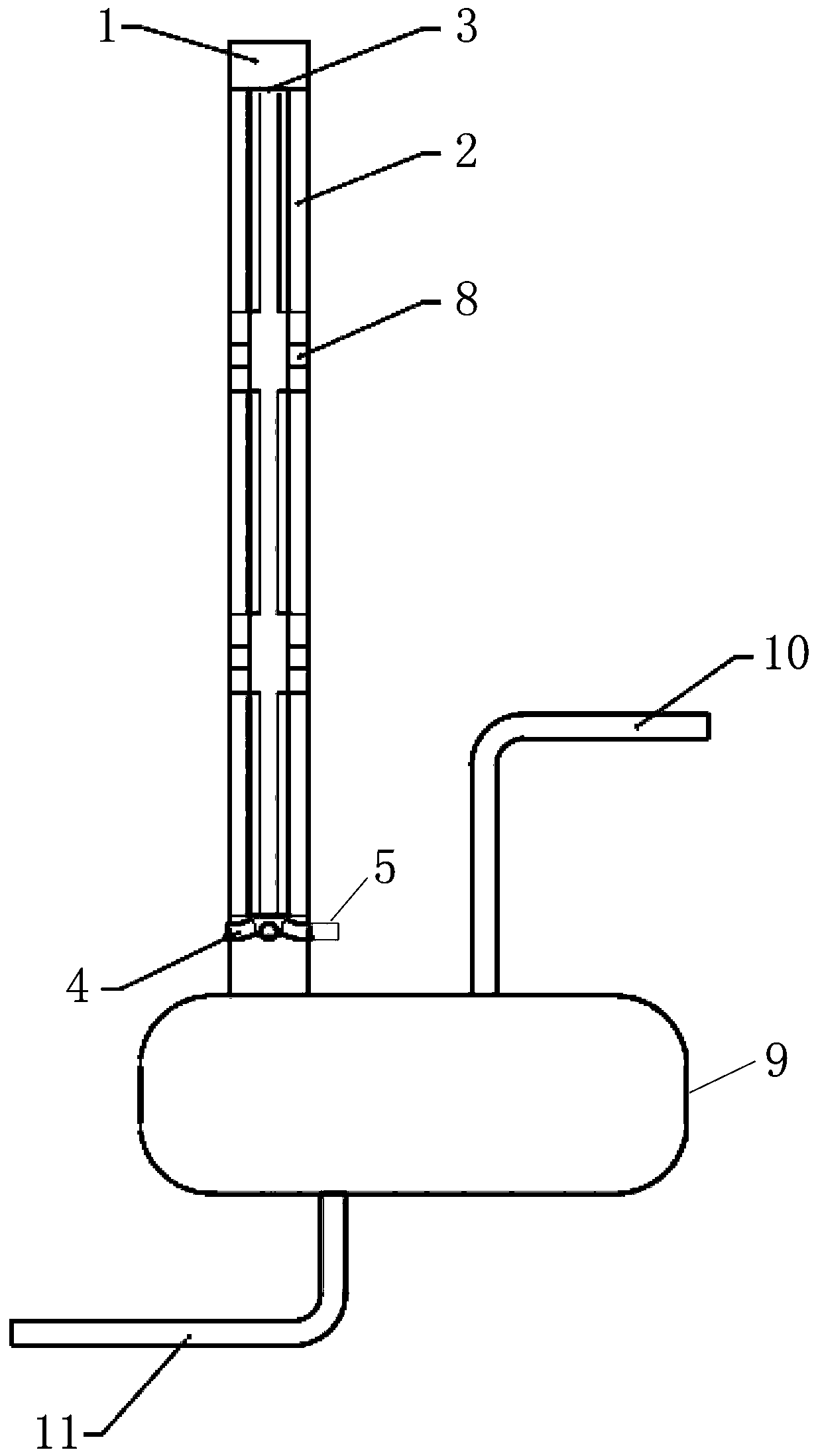

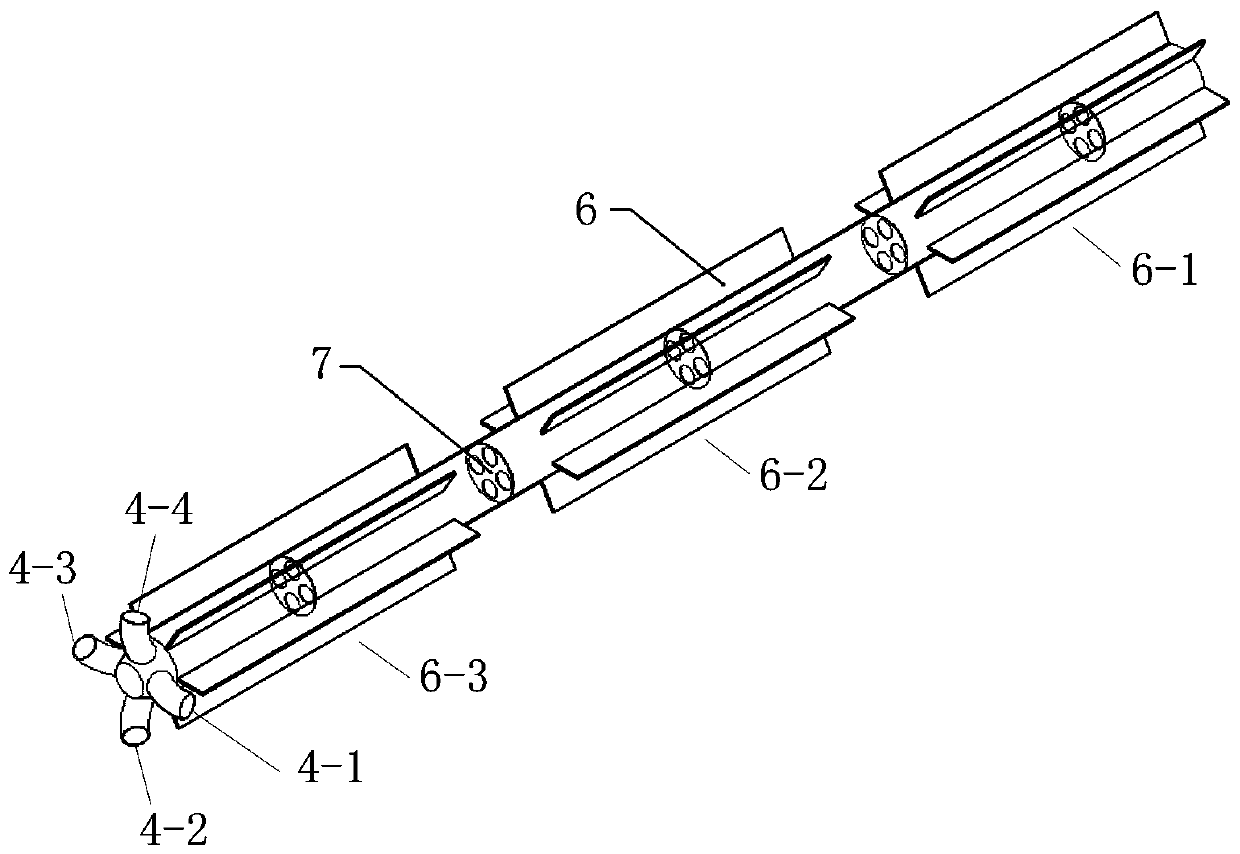

[0040] Such as figure 1 , figure 2 As shown, the present invention discloses a whitening device without external power for continuous expansion vessels, including continuous expansion vessels 9, an exhaust pipe 1 fixed above the continuous expansion vessels 9 and a steam discharge pipe 10, The condensed water discharge pipe 11 fixed below the continuous expansion vessel 9, the condensed pipe 2 and the connector 8 located in the exhaust pipe 1, and the Venturi tube 5 fixed on the condensed pipe 2, the exhaust pipe 1, the steam The discharge pipe 10 and the condensed water discharge pipe 11 are respectively connected and conducted with the series expansion vessels 9 , and the condensation pipe 2 is fixedly connected with the exhaust pipe 1 through the connecting piece 8 .

[0041] The upper end of the condensing pipe 2 is an air inlet 3, the lower end of the condensing pipe 2 is an air outlet 4, and the air outlet 4 passes through the side wall of the lower part of the exhaust...

Embodiment 2

[0065] The difference between embodiment 2 and embodiment 1 is that the condensation pipe 2 is made of aluminum alloy.

[0066] Such as figure 1 , figure 2 As shown, the present invention discloses a whitening device without external power for continuous expansion vessels, including continuous expansion vessels 9, an exhaust pipe 1 fixed above the continuous expansion vessels 9 and a steam discharge pipe 10, The condensed water discharge pipe 11 fixed below the continuous expansion vessel 9, the condensed pipe 2 and the connector 8 located in the exhaust pipe 1, and the Venturi tube 5 fixed on the condensed pipe 2, the exhaust pipe 1, the steam The discharge pipe 10 and the condensed water discharge pipe 11 are respectively connected and conducted with the series expansion vessels 9 , and the condensation pipe 2 is fixedly connected with the exhaust pipe 1 through the connecting piece 8 .

[0067] The upper end of the condensing pipe 2 is an air inlet 3, the lower end of th...

Embodiment 3

[0074] The difference between embodiment 3 and embodiment 1 is that the condensation pipe 2 is a pipe made of magnesium alloy.

[0075] Such as figure 1 , figure 2 As shown, the present invention discloses a whitening device without external power for continuous expansion vessels, including continuous expansion vessels 9, an exhaust pipe 1 fixed above the continuous expansion vessels 9 and a steam discharge pipe 10, The condensed water discharge pipe 11 fixed below the continuous expansion vessel 9, the condensed pipe 2 and the connector 8 located in the exhaust pipe 1, and the Venturi tube 5 fixed on the condensed pipe 2, the exhaust pipe 1, the steam The discharge pipe 10 and the condensed water discharge pipe 11 are respectively connected and conducted with the series expansion vessels 9 , and the condensation pipe 2 is fixedly connected with the exhaust pipe 1 through the connecting piece 8 .

[0076] The upper end of the condensing pipe 2 is an air inlet 3, the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com