Using method for universal angle milling head

A technology of angle and milling head, applied in the general control system, comprehensive factory control, program control, etc., can solve the problems of increased implementation cost, complicated operation and difficult operation of the measuring head system, and achieve low implementation cost and simple operation Fast, the effect of expanding the scope of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

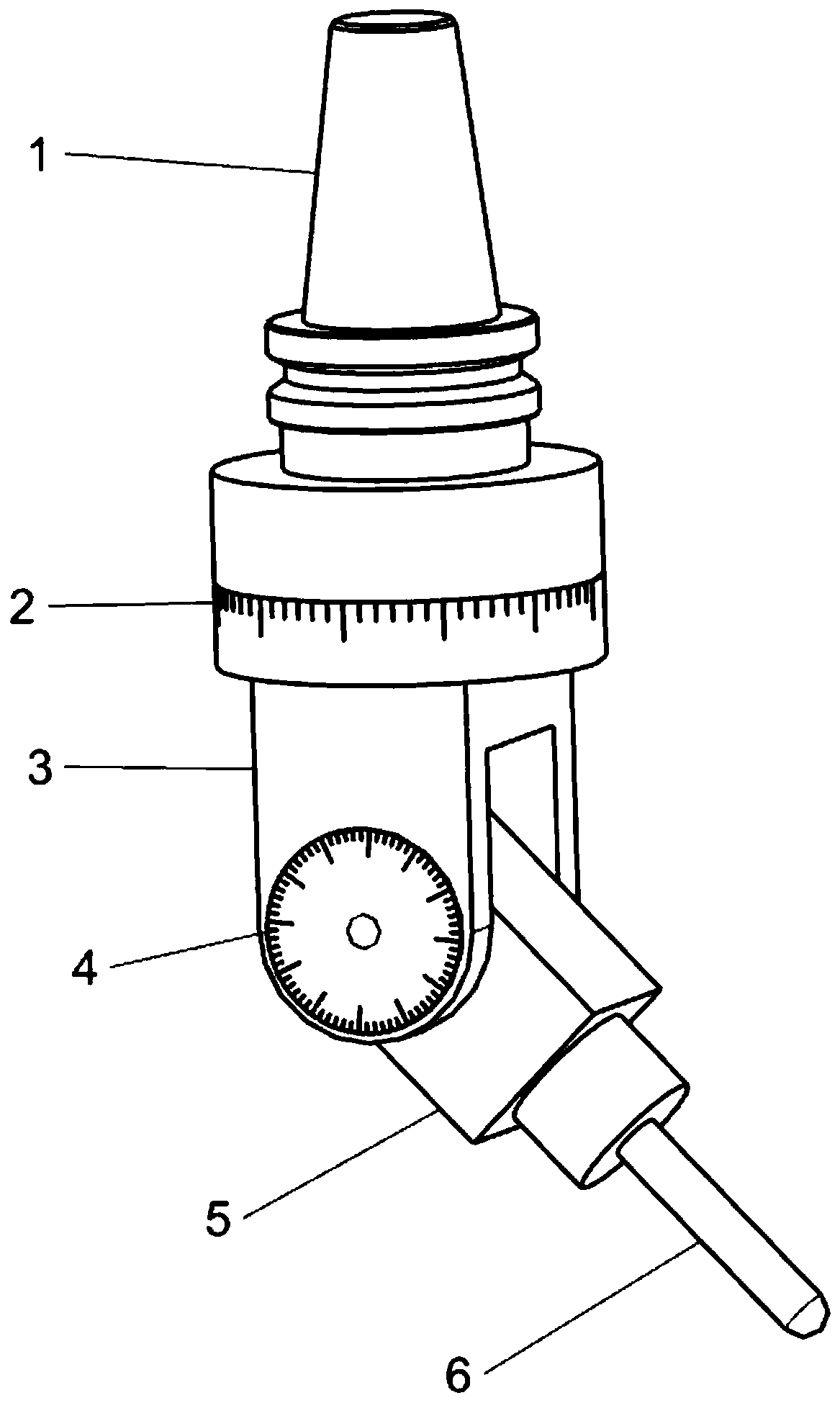

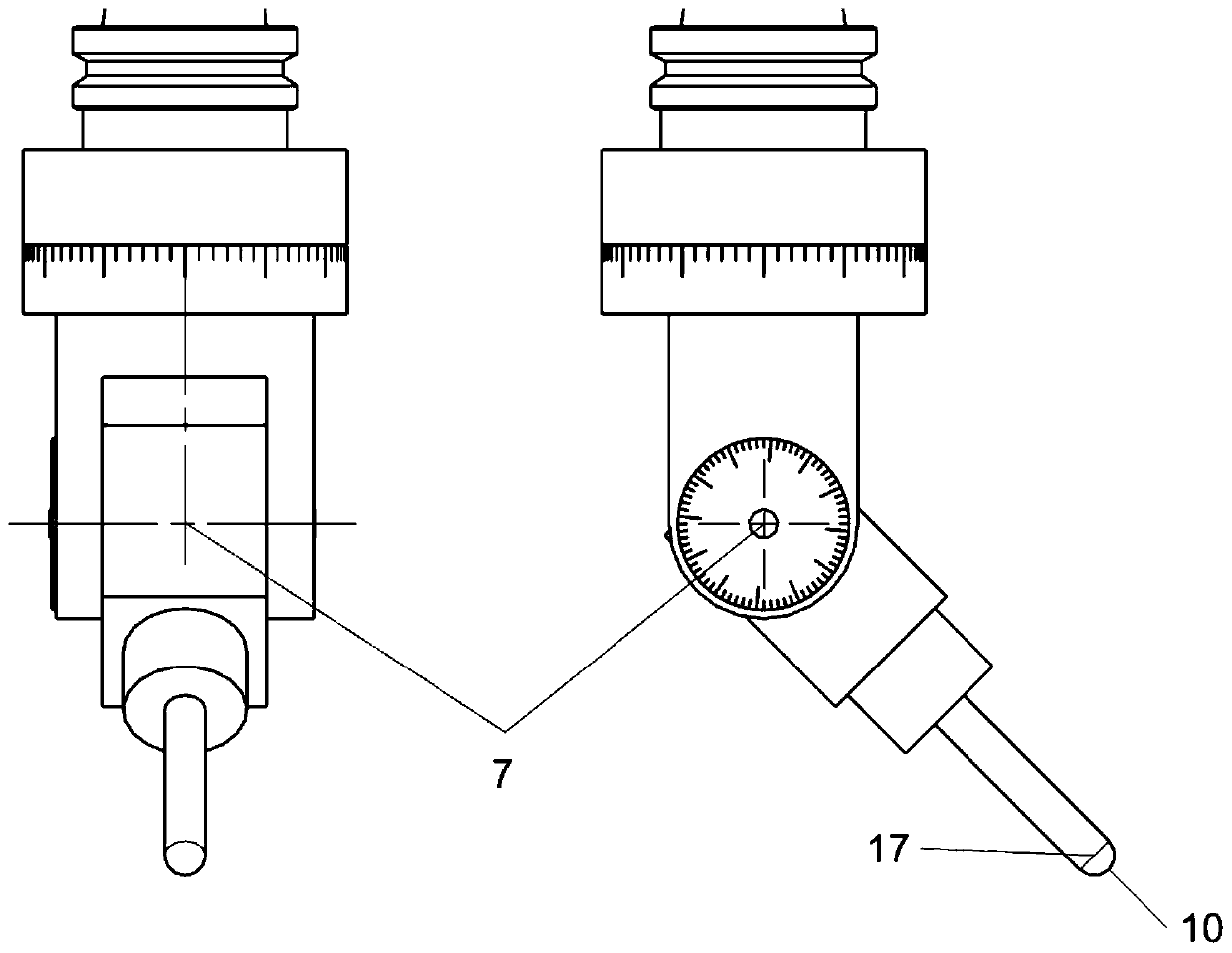

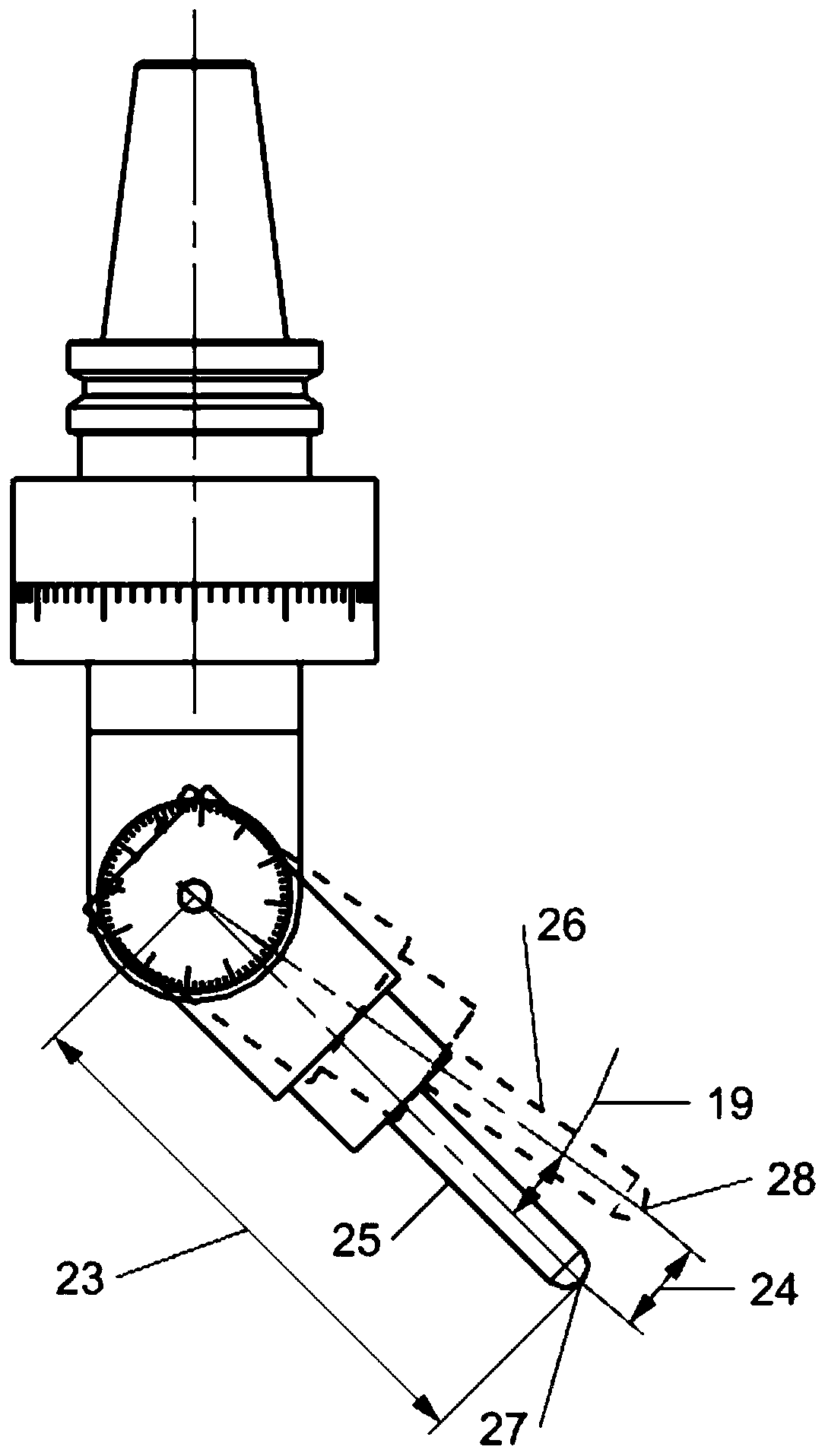

[0030] like figure 1 As shown, a method of using a universal angle milling head includes the following steps:

[0031] Step 1. Make the machining program of the workpiece in the CAD / CAM software, and select the center of the tool sphere for the tool position when the program is output;

[0032] Step 2. Align and install a square block on the machine tool, and determine the center point of the upper surface of the square block as the origin of the reference coordinate system;

[0033] Step 3. Install the workpiece, measure the position difference between the origin of the workpiece coordinate system and the origin of the reference coordinate system, and use it as the offset value between the origin of the reference coordinate system and the origin of the workpiece coordinate system and record it in the CNC system for the subsequent origin of the reference coordinate system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com