A high-temperature lithium secondary battery electrolyte and battery

A lithium secondary battery, electrolyte technology, applied in secondary batteries, lithium storage batteries, organic electrolytes, etc., can solve problems such as inability to achieve performance, improve high-temperature cycle life, inhibit gas generation, and improve high-temperature storage. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

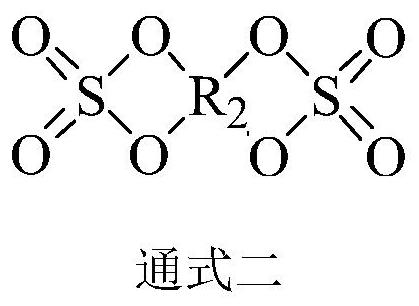

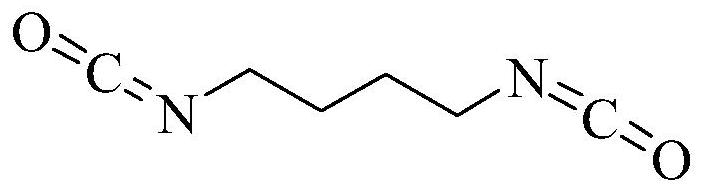

[0075] In this example, an electrolyte solution (100 g) comprising 1 M LiPF6 of a solvent in which ethylene carbonate and ethyl methyl carbonate are mixed in a mass ratio of 1:2 was prepared. Add the diisocyanate compound (0.03g) of the above chemical formula 1c and the bicyclic sulfate compound (1.0g) of the above chemical formula 2a to the electrolyte solution, the positive electrode material is LiNi0.8Co0.1Mn0.1O2; the negative electrode material is artificial graphite ; The diaphragm is a polyethylene film. A soft-pack lithium secondary battery was assembled according to a conventional method.

Embodiment 2

[0077] In place of the diisocyanate compound of Chemical Formula 1c (0.03 g), the diisocyanate compound of Chemical Formula 1c (0.5 g) and the bicyclic sulfate compound of Chemical Formula 2a (0.1 g) were added to the non-aqueous electrolyte of Example 1. g) A lithium secondary battery was prepared in the same manner as in Example 1, except for the bicyclic sulfate compound (1.0 g) of the above-mentioned Chemical Formula 2a.

Embodiment 3

[0079] In place of the diisocyanate compound of Chemical Formula 1c (0.03 g), the diisocyanate compound of Chemical Formula 1c (3.0 g) and the bicyclic sulfate compound of Chemical Formula 2a (1.0 g) were added to the non-aqueous electrolyte of Example 1. g) A lithium secondary battery was prepared in the same manner as in Example 1, except for the bicyclic sulfate compound (1.0 g) of the above-mentioned Chemical Formula 2a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com