Cement block of cement slope collapsing sand and preparation method thereof

A cement and block technology, applied in the field of building materials, to alleviate the shortage problem, realize the utilization of resources, and alleviate the damage of farmland

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

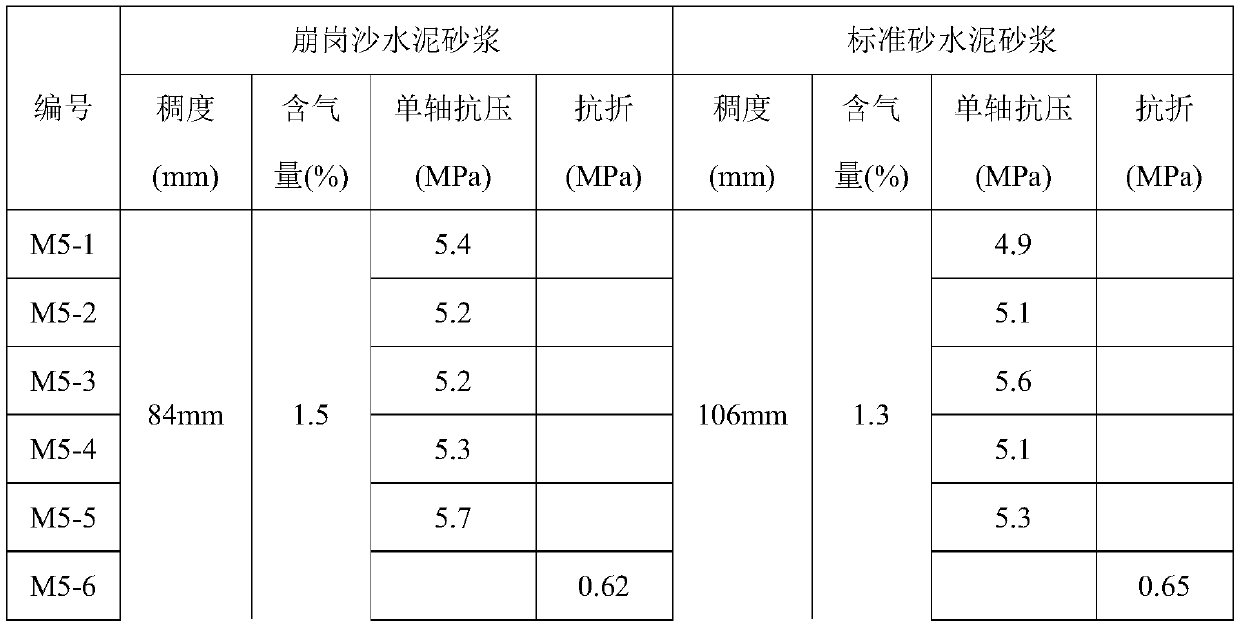

[0040] In order to meet the requirements of the M5 intensity level in this embodiment:

[0041] Benggang sand cement mortar is made of three components: water, cement and Benggang sand. The mass ratio of the components of Benggang sand cement mortar is water: cement: Benggang sand = 1:0.72:8.1.

[0042] Standard sand cement mortar is made of water, cement and standard sand. The mass ratio of standard sand cement mortar components is water: cement: standard sand = 1:0.72:8.1.

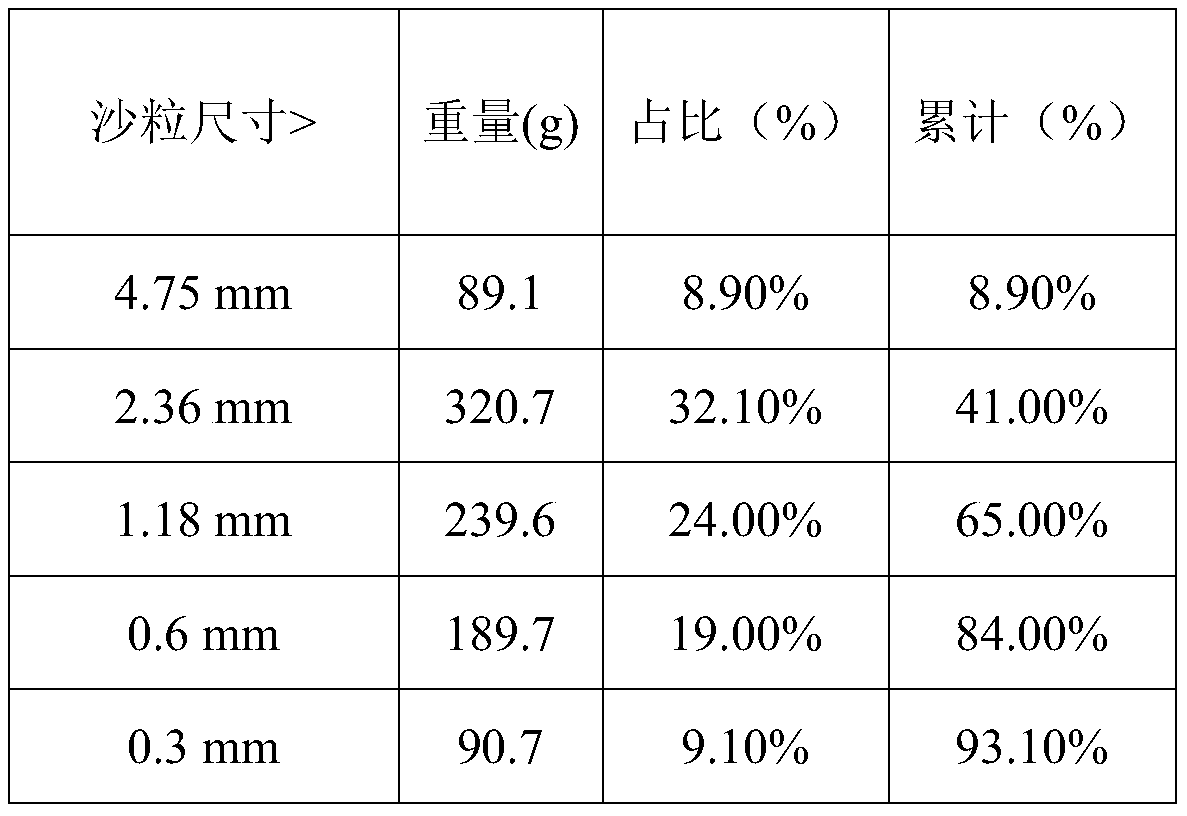

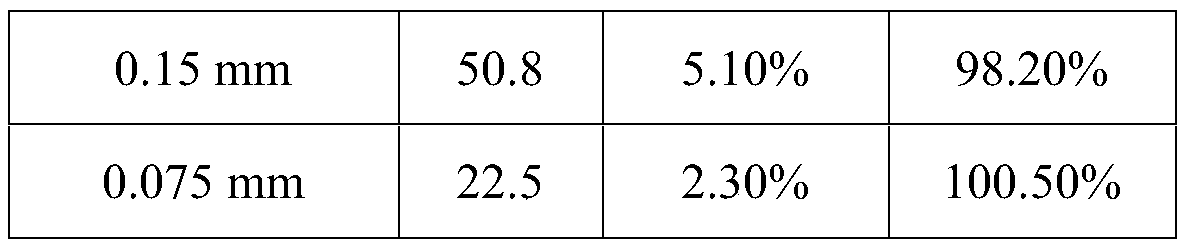

[0043] The preparation method of Bengang sand cement mortar is the same as that of standard sand cement mortar. Under the same conditions, after the mortar is evenly stirred, the consistency, air content, uniaxial compressive strength, and flexural strength are measured and compared with cement, and the consistency of the Bengang sand cement mortar is 84mm, which is 106mm less than the standard sand cement mortar; the air content is 1.5 % is slightly greater than 1.3% of river sand cement mortar; the aver...

Embodiment 2

[0048] In order to meet the requirements of the M10 intensity level in this embodiment:

[0049] Benggang sand cement mortar is made of three components: water, cement and Benggang sand. The mass ratio of the components of Benggang sand cement mortar is water: cement: Benggang sand = 1:0.9:8.1.

[0050] Standard sand cement mortar is made of three components: water, cement and standard sand. The mass ratio of standard sand cement mortar components is water: cement: standard sand = 1:0.9:8.1.

[0051] The preparation method of Bengang sand cement mortar is the same as that of standard sand cement mortar. Under the same conditions, after the mortar is evenly stirred, the consistency, air content, uniaxial compressive strength, and flexural strength are measured and compared with cement, and the consistency of the Bengang sand cement mortar is 84mm, which is 98mm less than the standard sand cement mortar; the air content is 1.8 % is slightly greater than 1.4% of river sand cemen...

Embodiment 3

[0056] This embodiment is to meet the requirements of the M15 intensity level:

[0057] Benggang sand cement mortar is made of three components: water, cement and Benggang sand. The mass ratio of the components of Benggang sand cement mortar is water: cement: Benggang sand = 1:1.1:8.1.

[0058] Standard sand cement mortar is made of three components: water, cement and standard sand. The mass ratio of standard sand cement mortar components is water: cement: standard sand = 1:1.1:8.1.

[0059] The preparation method of Bengang sand cement mortar is the same as that of standard sand cement mortar. Under the same conditions, after the mortar is evenly stirred, the consistency, air content, uniaxial compressive strength, and flexural strength are measured and compared with cement, and the consistency of the Bengang sand cement mortar is 72mm, which is 99mm less than the standard sand cement mortar; the air content is 1.7 % is slightly greater than 1.4% of river sand cement mortar;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com