Optical observation window capable of being used in high-temperature and high-pressure environment

A high temperature and high pressure, observation window technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc. Achieving the effect of wide application, reducing safety hazards, and simple cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with accompanying drawing

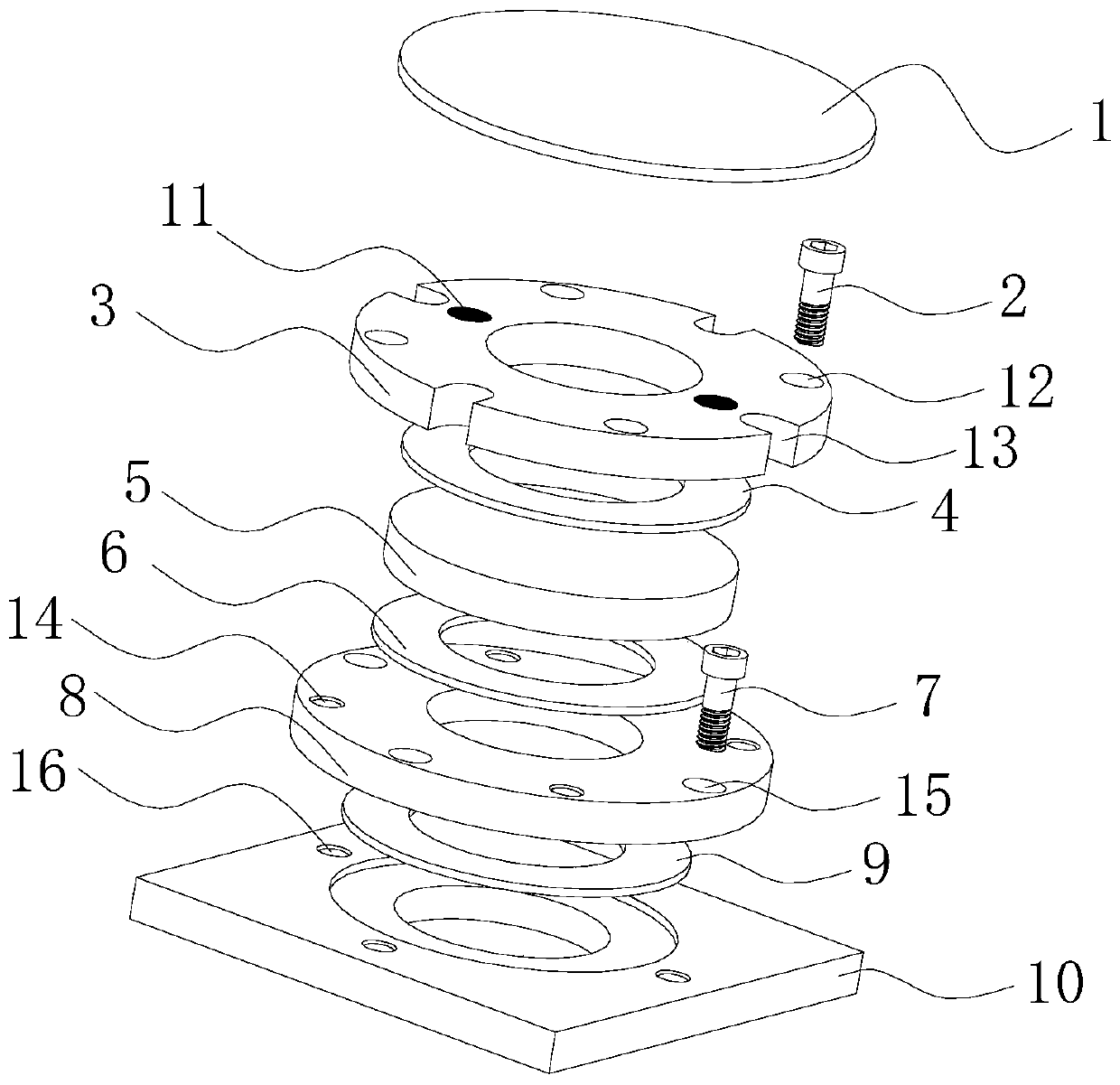

[0022] Such as figure 1 As shown, it is an optical observation window that can be used in high temperature and high pressure environment provided by the present invention. The optical observation window includes a protective cover plate 1, an upper flange plate 3, an upper sealing gasket 4, a light-transmitting material 5, a lower sealing gasket 6, a lower flange plate 8 and a sealing gasket for installing the observation window arranged in sequence 9;

[0023] The observation window also includes an observation window assembly bolt 2 and a bolt 7 for installing the observation window;

[0024] The observation window assembly bolt 2 is used to assemble the observation window assembly;

[0025] The bolts 7 for installing the observation window are used to install the observation window on the observation object.

[0026] A magnet 11 is buried on the upper flange, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com