Large-size frozen soil true triaxial loading test device

A loading test device, true triaxial technology, applied in the direction of measuring device, using applied repetitive force/pulsation force to test material strength, using applied stable tension/pressure to test material strength, etc., can solve the problem that dynamic monitoring and real-time display cannot be realized , Can not be used to study problems such as multi-field coupling and mutual feedback effects, to achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

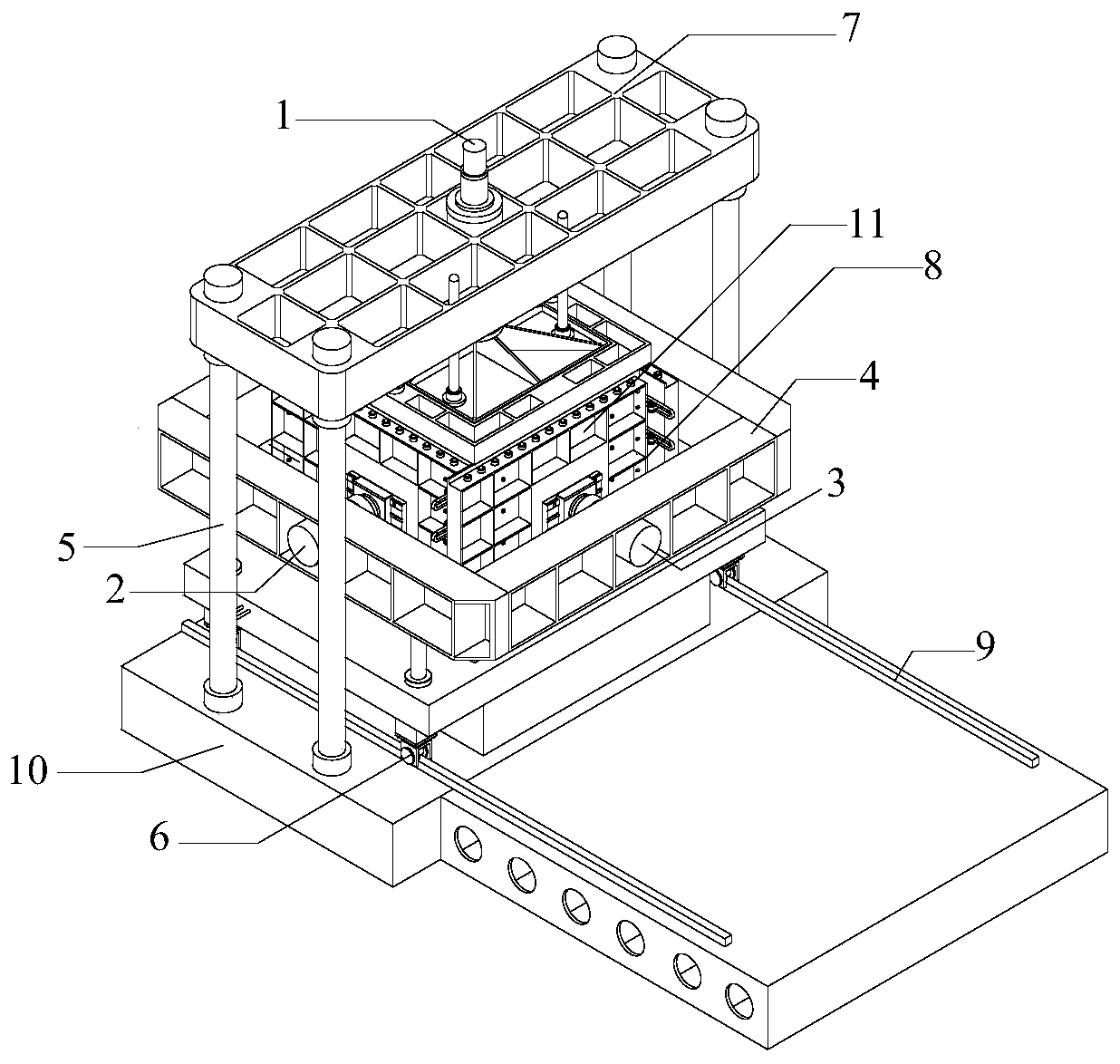

[0022] The main structure of this embodiment includes five major systems: a main frame, a loading system, a hydraulic servo system, a stress-strain measurement system, and a data acquisition system. The reaction force frame 7 of the system and the base 10 are connected by fixed nuts through four columns. After the frame is cast, the overall normalizing process is performed, and all surfaces are cut. The columns are made of 45# steel (quenched and tempered HBS220-250). The surface is polished and plated with hard chrome, and the surface of the fixed nut is polished and plated with nickel to ensure a smooth and flat appearance. The length × width × height of the main frame is 4700mm × 3200mm × 3400mm, the weight is about 20 tons, and the performance level of each column reaches Grade 12.9, the tensile strength is 1.2MPa; the performance grade of each nut reaches Grade 12, the hydraulic nut is locked, and the locking force reaches 1000kN, which can eliminate the tensile force. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com