Degradable wound dressing preparation method and burdening equipment for dressing

A technology of wound dressing and batching equipment, which is applied in the direction of chemical instruments and methods, dissolving, and mixers with rotating stirring devices, etc. It can solve the problems of material and structure wound skin hypoxia, wound suppuration or inflammation, and poor use effect. Achieve the effect of improving the mixing effect, convenient operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

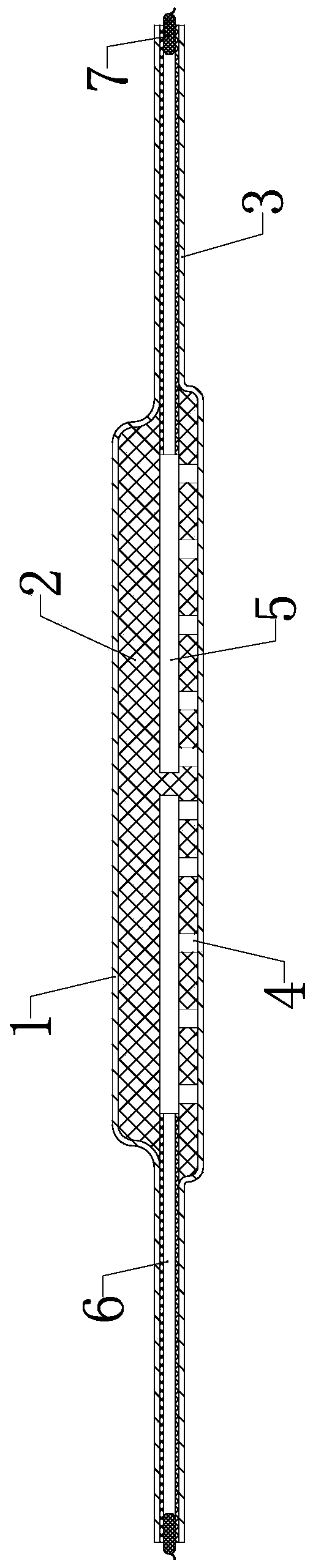

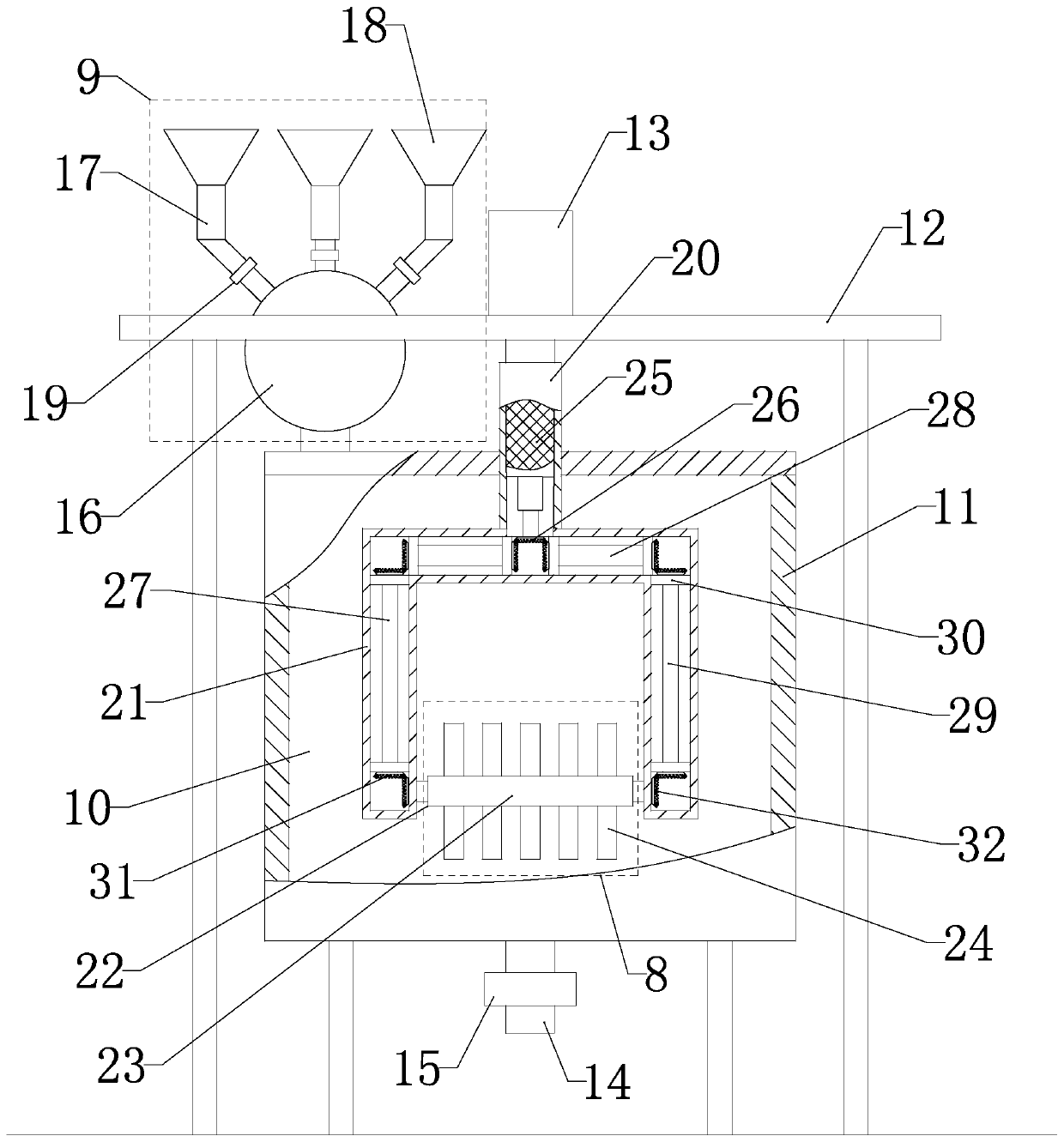

[0043] like Figure 1-2 As shown in , a degradable wound dressing includes an outer film adhesive layer 1, a dressing layer 2, and a protective film 3 arranged sequentially from the inside to the outside, and several circulation holes 4 are arranged in the middle section of the dressing layer 2, The bottoms of the flow holes 4 all pass through the bottom of the dressing layer 2, and a number of dosing channels 5 are arranged in the middle section of the thickness of the dressing layer 2, and a dosing hose 6 is glued inside the dosing channels 5, The outer membrane adhesive layer 1 is a degradable semipermeable mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com