A kind of saturated steam treatment equipment for fiberboard raw material pulping

A technology for processing equipment and fiberboard, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as the inability to improve the utilization rate of saturated steam, reduce resource loss, ensure stable operation, and ensure efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

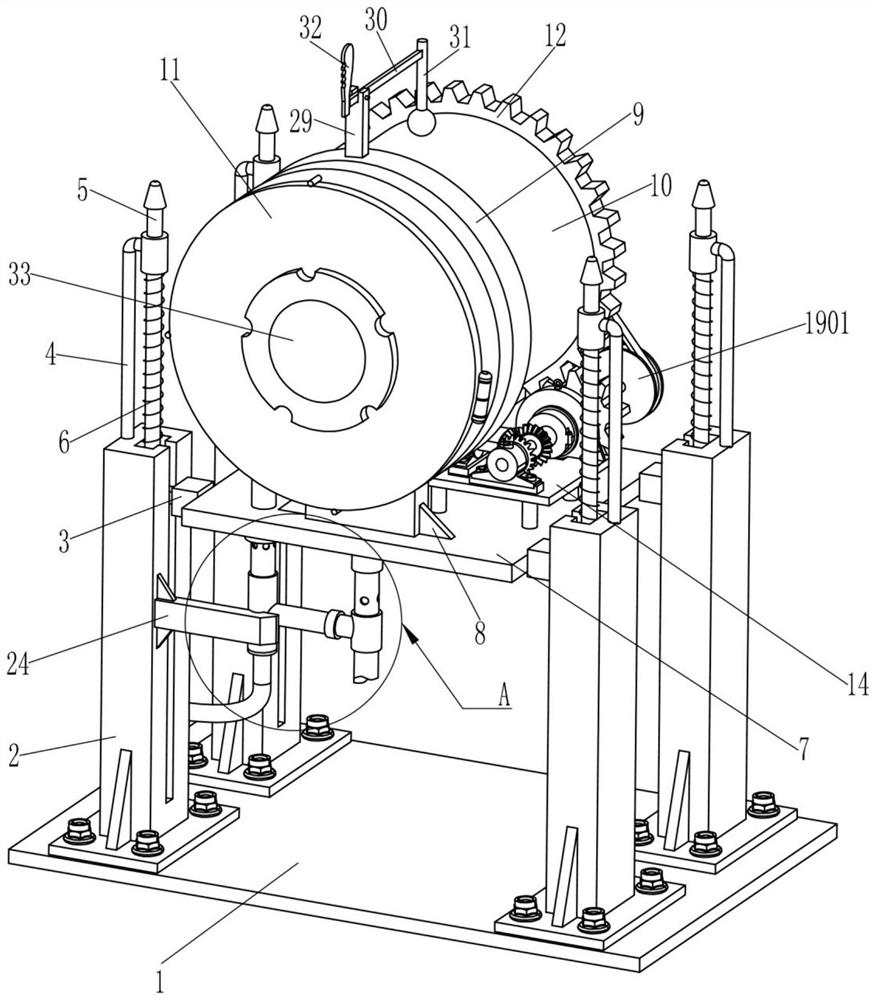

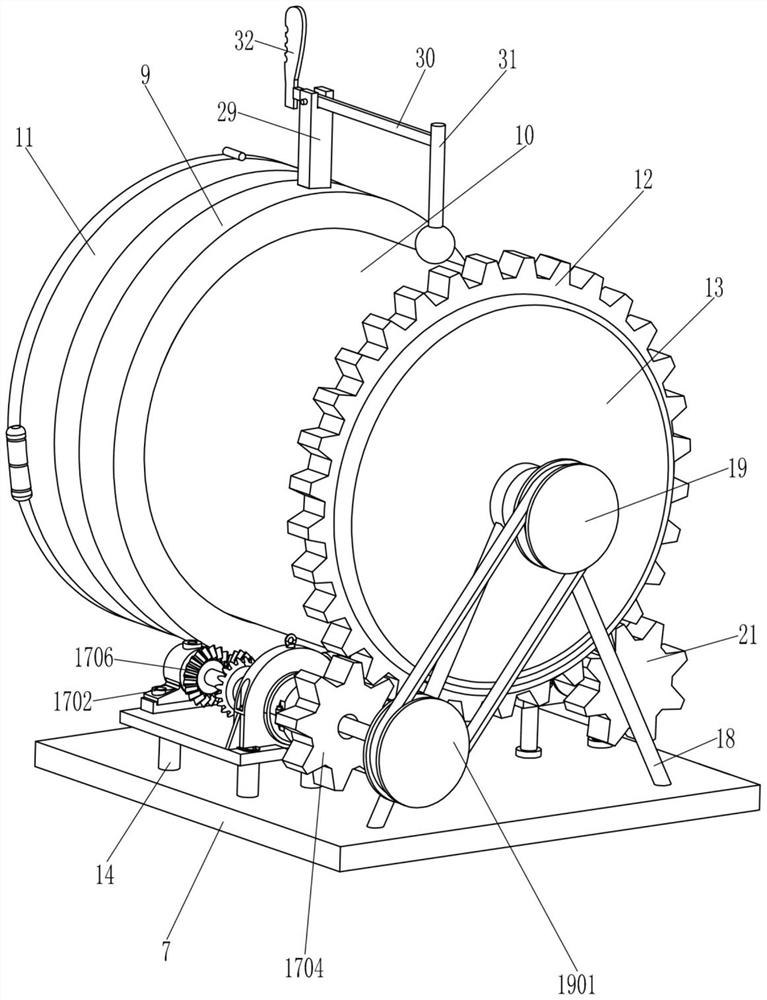

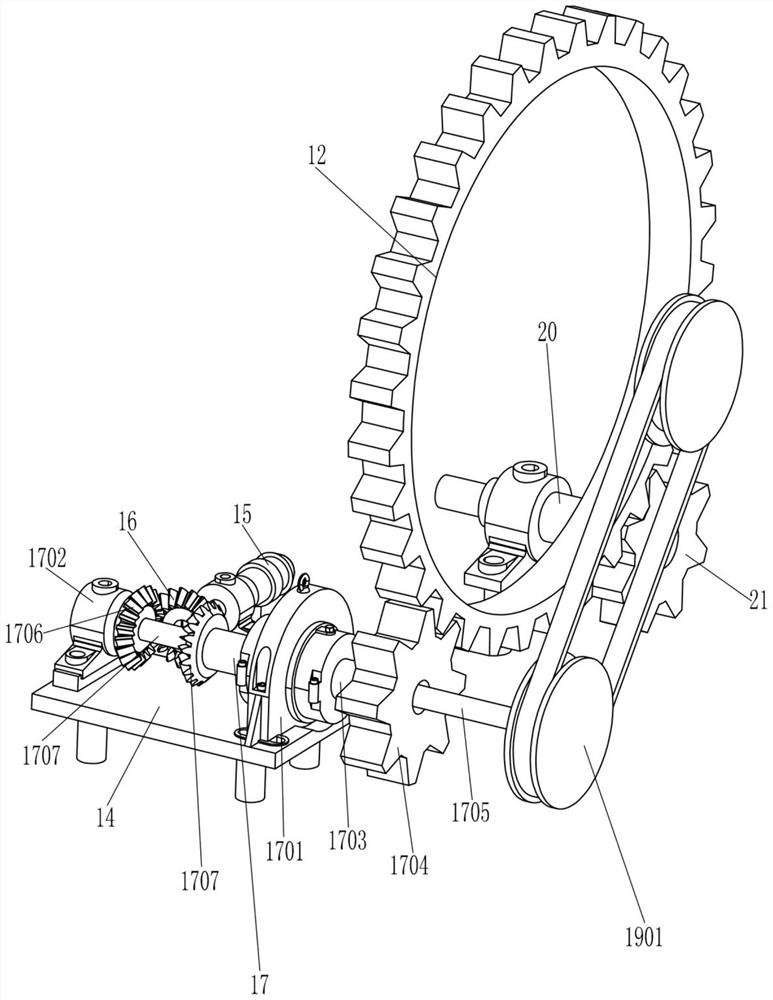

[0025] A saturated steam treatment equipment for fiberboard raw material pulping, such as Figure 1-6 As shown, it includes a bottom plate 1, a guide frame 2, a sliding plate 3, a guide frame 4, a guide rod 5, a first compression spring 6, a horizontal plate 7, a support seat 8, a slotted ring 9, a rotating opening cylinder 10, an opening and closing Assembly 11, gear ring 12, filter mesh cylinder 13, mounting plate 14, reduction motor 15, first bevel gear 16, reverse drive device 17, mounting seat 18, stirring device 19, base 20, second gear 21, air intake pipe 22 and the drain pipe 23, four guide frames 2 are arranged around the top of the bottom plate 1, the guide frame 2 is slidably connected with the sliding plate 3, the top of the guide frame 2 is provided with a guide frame 4, and the guide frame 4 is slidably connected with a guide frame. The rod 5, the first compression spring 6 is connected between the guide rod 5 and the guide frame 4, the inner side of the sliding ...

Embodiment 2

[0030] On the basis of Example 1, as Image 6 As shown, it also includes a mounting frame 24, a three-way pipe 25, a one-way valve 26, a guide sleeve 27 and an air intake hose 28. One side of the guide frame 2 is provided with a mounting frame 24, and the mounting frame 24 is provided with a three-way pipe. 25. The lower part of the intake pipe 22 is slidably located in the tee pipe 25, the tee pipe 25 is provided with a one-way valve 26, one end of the tee pipe 25 is provided with a guide sleeve 27, and the drain pipe 23 is slidably located in the guide sleeve 27, An air intake hose 28 is connected to the bottom end of the three-way pipe 25 .

[0031] When the horizontal plate 7 moves downward, the horizontal plate 7 drives the intake pipe 22 and the liquid discharge pipe 23 to move downward, and the liquid discharge pipe 23 and the intake pipe 22 are both provided with small holes. When the fiberboard material is used, the filter mesh cylinder 13 presses the horizontal plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com