Gleeble thermal simulated test machine pipe extrusion mold and use method thereof

A technology of extrusion dies and testing machines, applied in the field of material processing, to achieve the effects of wide application, improved product quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

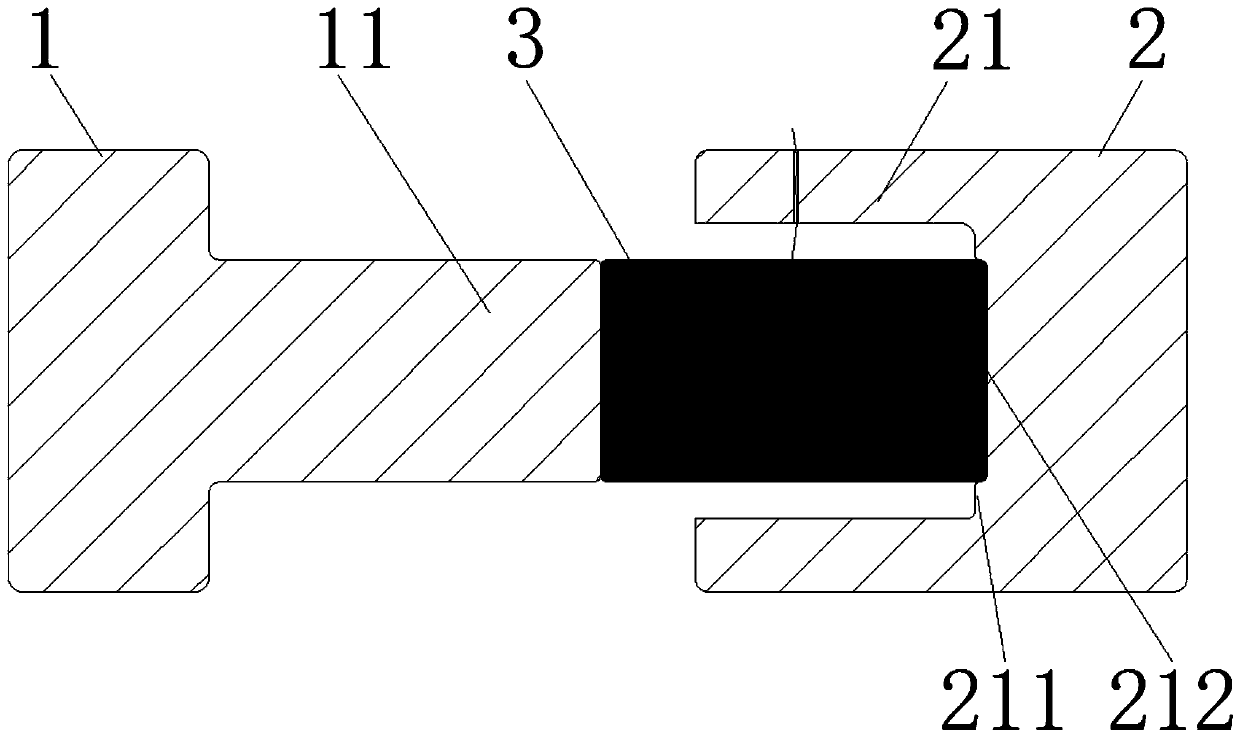

[0032] A pipe extrusion die for a Gleeble thermal simulation testing machine, including a left mold 1 and a right mold 2, one end of the left mold 1 is connected to the mechanical transmission pressure head of the Gleeble thermal simulation testing machine, and the size of the connecting end of the left mold is The same size as the mechanical transmission indenter, one end surface of the right mold 2 is connected with the bearing indenter of the Gleeble thermal simulation testing machine and the size of the connecting end of the right mold is the same as that of the bearing indenter.

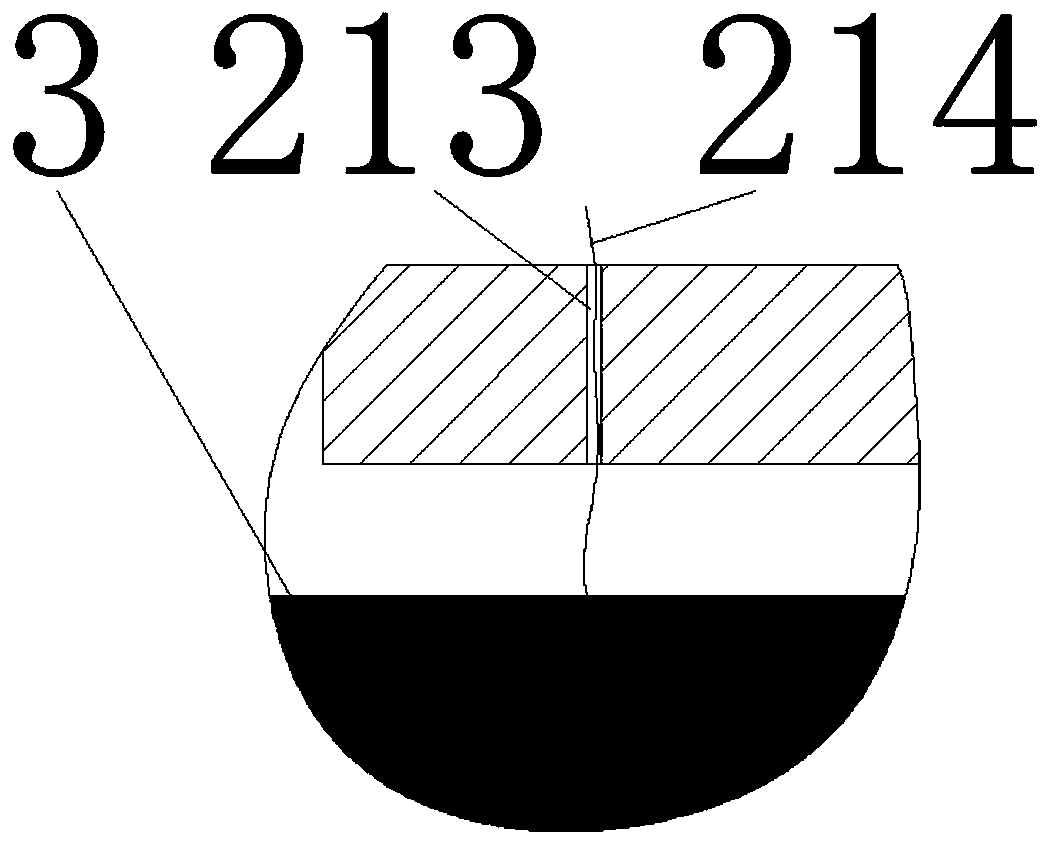

[0033] On the basis of the above structure, such as Figure 1-3 As shown, the other end surface of the left mold 1 is fixed with a cylindrical left mold lug 11, and the other end surface of the right mold 2 is provided with a hollow cylinder that matches the left mold lug 11. The extrusion concave cavity 21, and the diameter of the extrusion concave cavity 21 is greater than the diameter of the ...

Embodiment 2

[0037] On the basis of the structure of the pipe extrusion die of a Gleeble thermal simulation testing machine disclosed in Example 1, further technical improvements are made. The specific improved structure is as follows:

[0038] The position of the positioning groove 212 is set at the center position of the side surface 211 where it is located in the extrusion cavity 21 . In this way, the extruded sample 3 is conveniently snapped into the positioning groove to play a positioning role, and at the same time, the sample is ensured to be in the middle of the extruded cavity 21 . In addition, the diameter of the positioning groove 212 is the same as that of the extrusion sample 3 .

[0039]Simultaneously, in order to ensure the accuracy of extrusion, it is also ensured that the size of the left die bump 11 is the same as that of the extrusion sample 3 .

Embodiment 3

[0041] On the basis of the structure of a pipe extrusion die of a Gleeble thermal simulation testing machine disclosed in Example 2, further technical improvements are made. The specific improved structure is as follows:

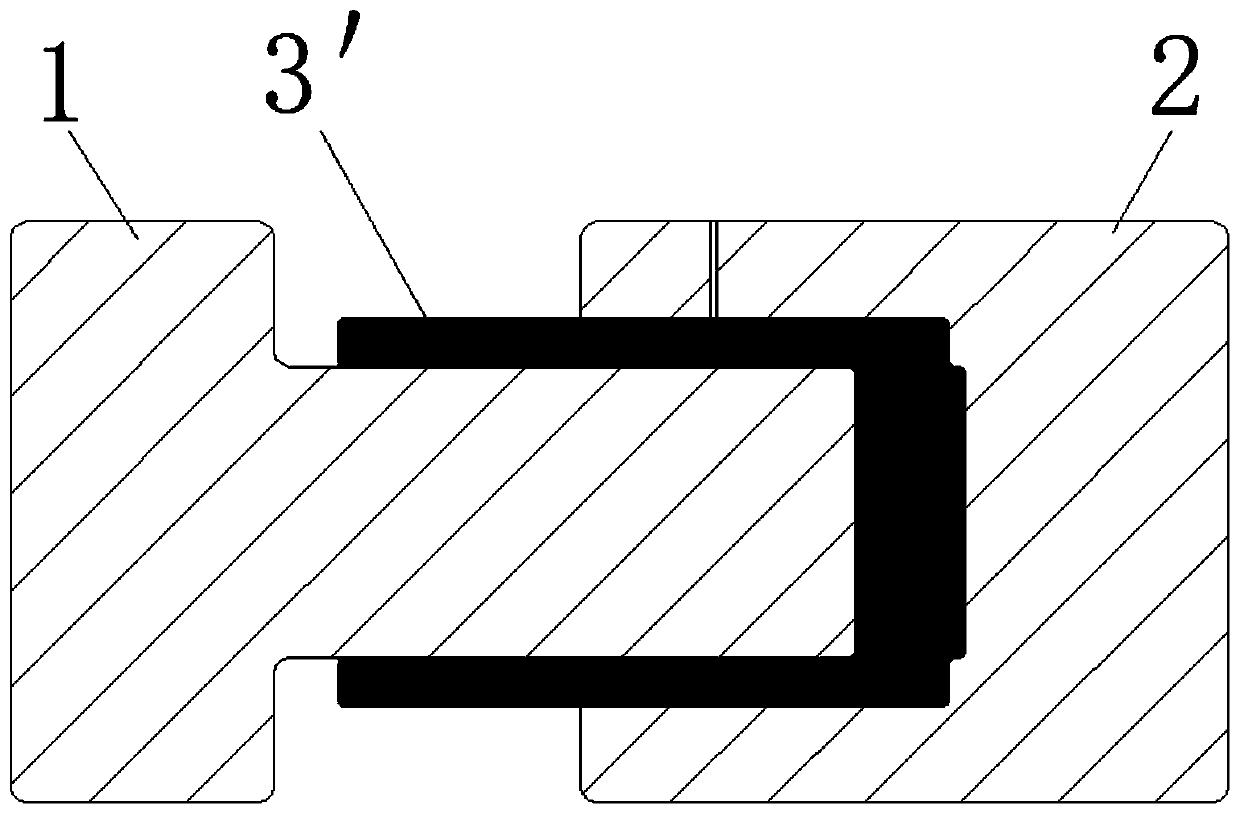

[0042] On the other end face of the left mold 1, a detachable cylindrical left mold lug 11 is arranged. Because the inner diameter of the extruded pipe material 3' is the same as the diameter of the left die bump 11. Therefore, the inner diameter of the extruded pipe material 3 ′ can be determined by changing the diameter of the left mold block 11 . In this way, pipes of various specifications can be extruded conveniently.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com