Glass deep machining production line of shower room

A glass deep processing and production line technology, applied in glass tempering, stone processing equipment, glass manufacturing equipment, etc., can solve the problems of long drilling time, large drilling process rhythm, drilling process interruption, etc., to improve the overall Line production efficiency and drilling accuracy and quality, reducing the drilling process beat, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

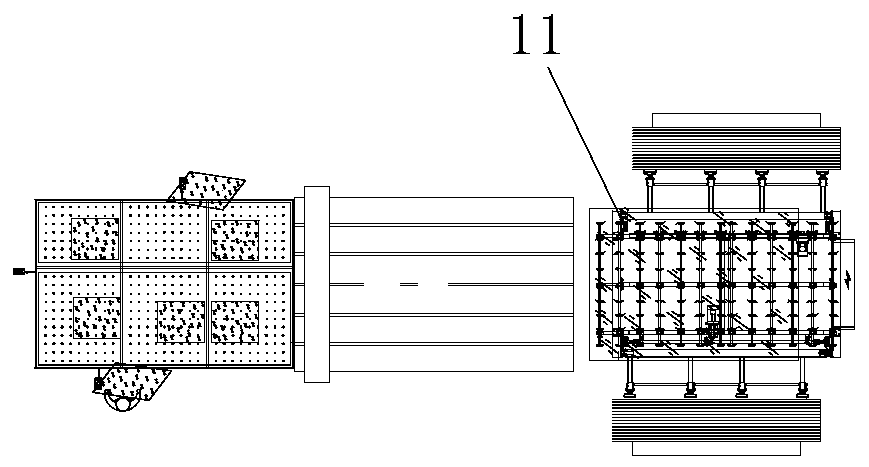

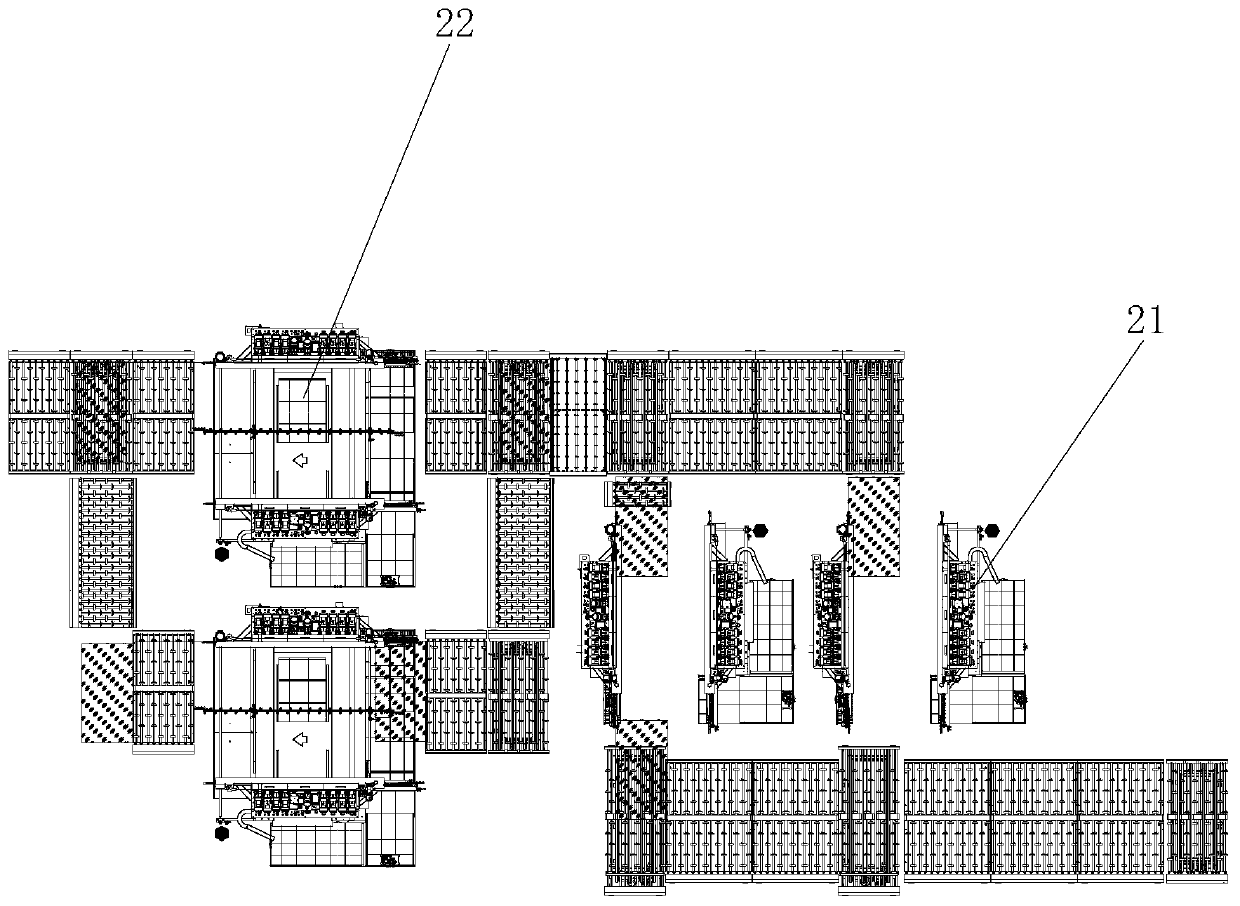

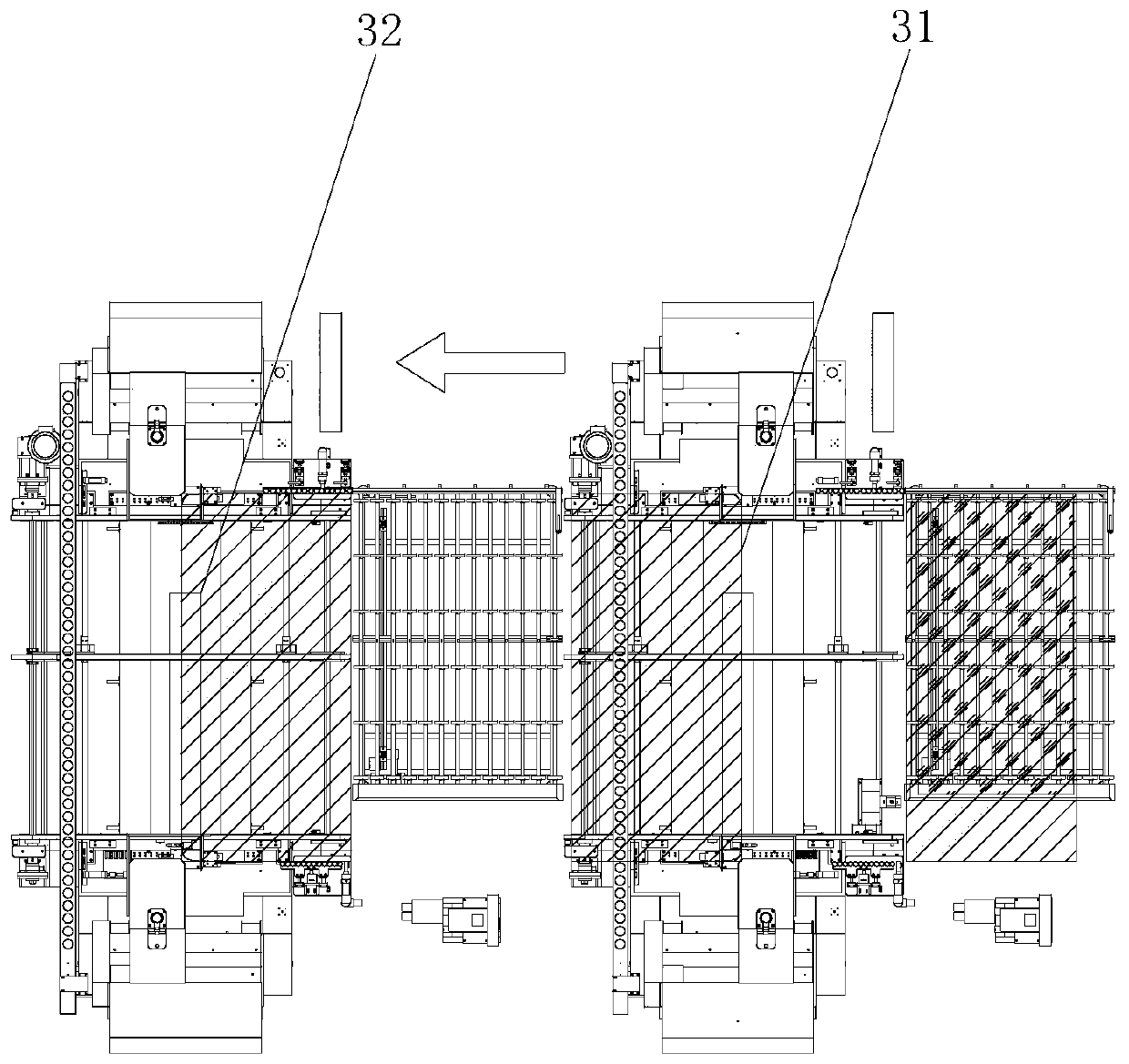

[0050] see Figure 1 to Figure 11 , Figure 13 , Figure 14 ,, a shower room glass deep processing production line, used for processing glass workpieces, including cutting system 1, edging system 2, chamfering system 3, tempering system 5, control system, drilling system 4, easy cleaning system 6 , film system 7 and transmission system, etc. The control system connects and controls each system and makes its tempo match with the production tempo of the whole line.

[0051] The original glass sheet or glass workpiece is transmitted through the transmission device among the cutting system 1, edging system 2, chamfering system 3, drilling system 4, tempering system 5, easy-cleaning system 6, and film sticking system 7. The conveying system includes a conveying platform, and the conveying platform includes a support and a plurality of conveying rollers arranged at intervals on the support and the like.

[0052] In addition, scanning units can be installed at the feed ports of t...

Embodiment 2

[0084] see Figure 12 , a shower room glass deep processing production line, its main structure is the same as that of Embodiment 1, the difference is that it is a 6mm-6-hole flat glass production line. Its easy-cleaning system 6 and film sticking system 7 are different from the first embodiment, and the coating system 8 is not provided.

[0085] Specifically, in the S03 line, it adopts the flat glass easy-clean line, and the film sticking system 7 corresponds to the flat glass film sticking line.

[0086] In this embodiment, the average beat of the easy-clean system 6 is 13.3 seconds, and the average beat of the film sticking system 7 is 10 seconds, matching the beat of the entire production line.

Embodiment 3

[0088] see Figure 13 , a shower room glass deep processing production line, its main structure is the same as that of Embodiment 1, the difference is that it is a mixed production line of 6mm-6 hole flat glass and curved glass. Its easy-cleaning system 6 and film sticking system 7 are different from Embodiment 1.

[0089] Specifically, in the S03 line, it adopts the curved glass easy-to-clean line, and the film sticking system 7 corresponds to the curved glass film sticking line.

[0090] In this embodiment, the average beat of the easy-clean system 6 is 13.3 seconds, and the average beat of the film sticking system 7 is 10 seconds, matching the beat of the entire production line.

[0091] The present invention scans the two-dimensional code on the glass workpiece in the shower room by a two-dimensional code scanner to obtain the two-dimensional code code of the glass workpiece, and the control system outputs the process parameters of the equipment according to the code or g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com