Semi-automatic cement mixing pile strength uniformity device

A cement mixing pile, semi-automatic technology, applied in mixing plants, clay preparation devices, mixing operation control devices, etc., can solve the problems of inability to quantitatively control the amount of cement, lack of monitoring of pile quality, uneven depth distribution, etc. The pile quality effect is remarkable, the construction safety requirements are met, and the semi-automation is remarkable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

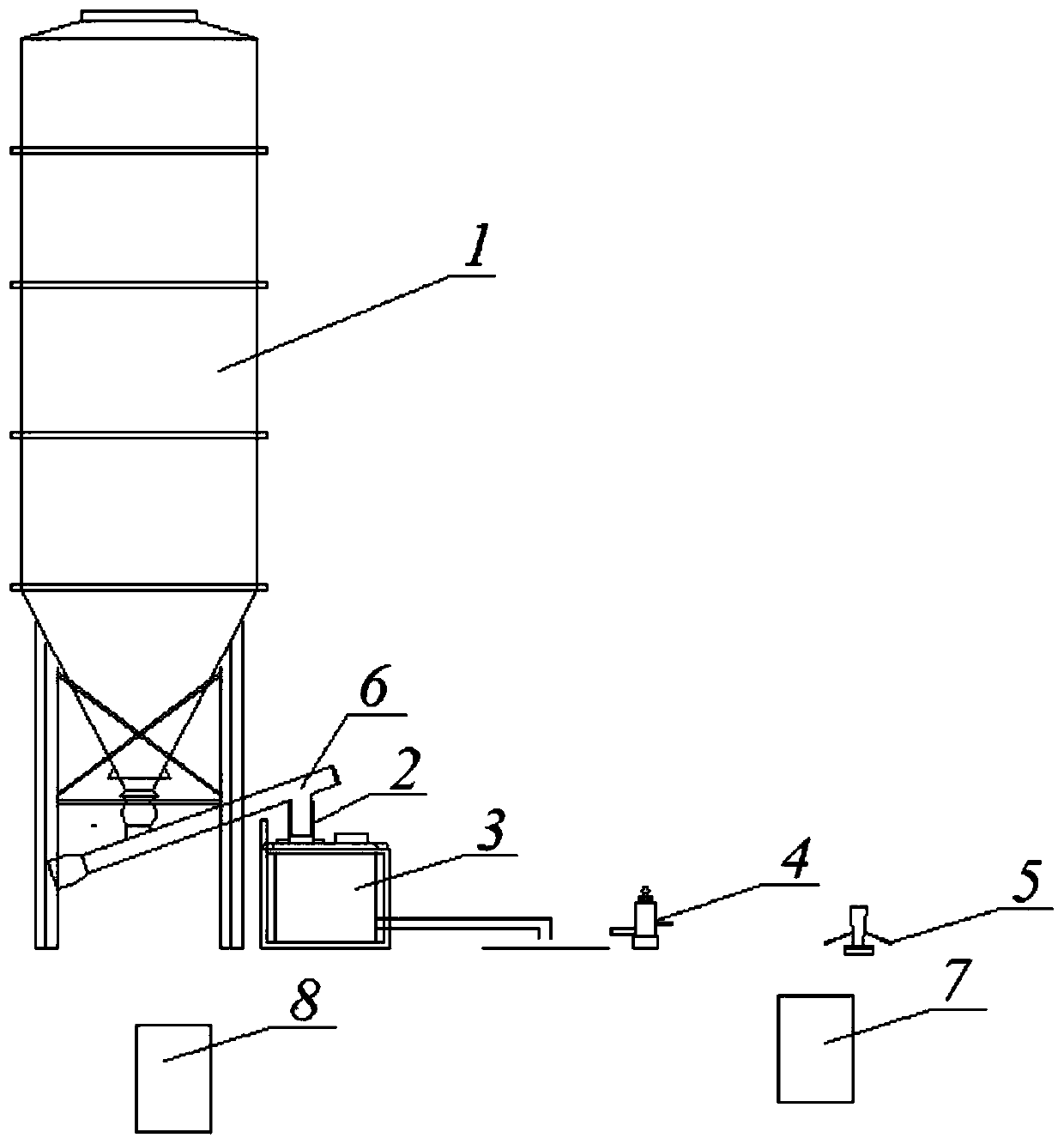

[0013] Embodiments of the present invention: the structure diagram of the semi-automatic cement mixing pile strength uniformity device of the present invention is as follows figure 1 As shown, including cement storage tank 1, JLSNC 30T is used to store cement, and LSY219 screw conveyor 6 is used. The cement delivery pipe 2 is used to connect the cement storage tank to the automatic mixer, so that the cement is delivered to the automatic mixer. Cement slurry automatic mixer 3 Its function is to weigh water and cement according to the water-cement ratio according to the design requirements, and stir them into a uniform slurry. The effect of the mud pump 4 is to pump the mud pool slurry to the pile driver to control the spray flow. Its effect of pressure surge tank 5 is to stabilize pressure. During construction, first put water into the cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com