Copolymerized nylon 612 material

A technology of copolymerizing nylon and nylon, which is applied in the field of materials, and can solve the problems of reduced rigidity, surface brightness, and chemical resistance that need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of Copolymerized Nylon 612A

[0036] Raw material: nylon 612 monomer: 97 parts, nylon 6I monomer 3 parts, antioxidant 0.08 part, distilled water: 100 parts

[0037] 1. Weigh 9.7 kg of nylon 612 monomer, 0.3 kg of nylon 6I monomer, 8 g of antioxidant, and 10 kg of distilled water into a 27L reactor, heat up to 90-105°C, start stirring, and react for 0.5 hours , continue to heat up to 205-260°C, when the pressure reaches 1.5-1.8MPa, react for 2-4 hours, then maintain the temperature at 205-260°C and exhaust to normal pressure, the reaction ends.

[0038] 2. Inject carbon dioxide or other inert gas to press out the material from the reaction kettle, cool it in a water tank, and drag it to a pelletizer for pelletizing to obtain the copolymerized nylon 612A product.

experiment example 1

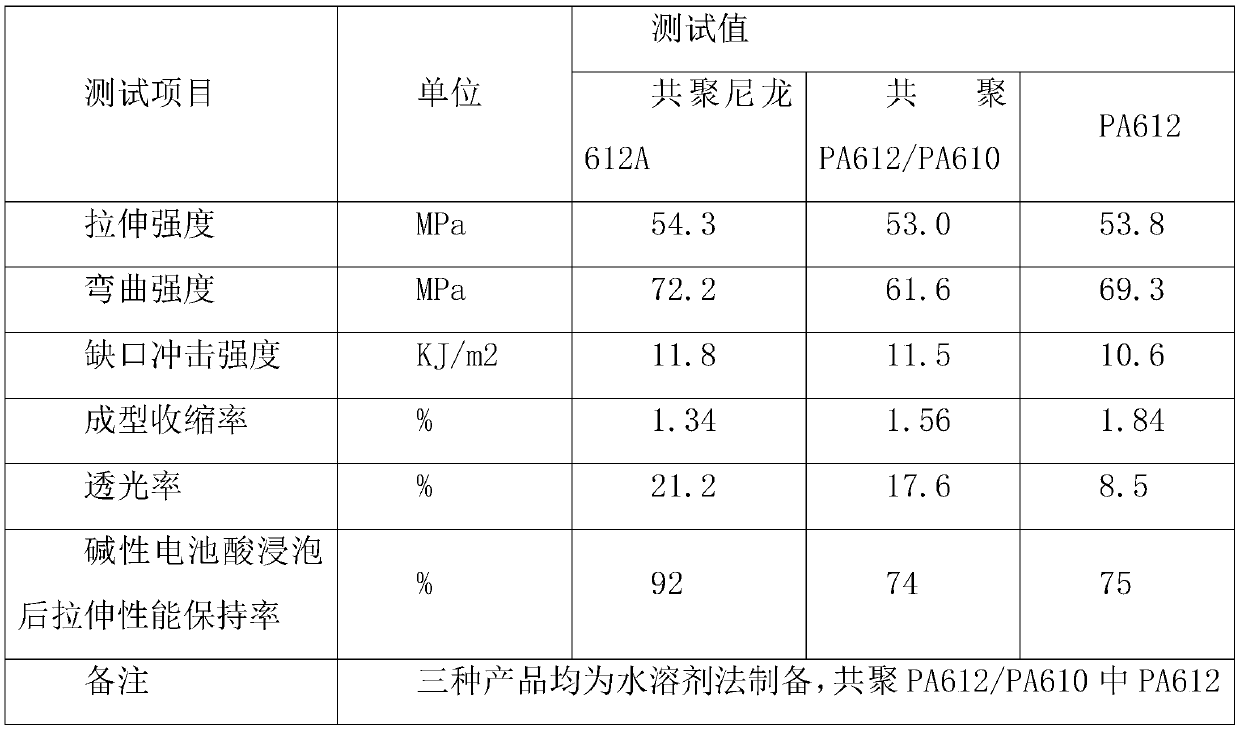

[0039] Experimental example 1: Product performance test of copolymerized nylon 612A

[0040] After drying the copolymerized nylon 612A prepared in Example 1, use an injection molding machine to make various standard specimens, and place it for 24 hours for testing; injection molding machine temperature: 230°C, 235°C, 235°C; injection speed 60g / s, injection time 12s, The injection pressure is 36MPa, the holding pressure is 28MPa, and the holding time is 25s.

[0041] The test results are as follows:

[0042]

[0043]

Embodiment 2

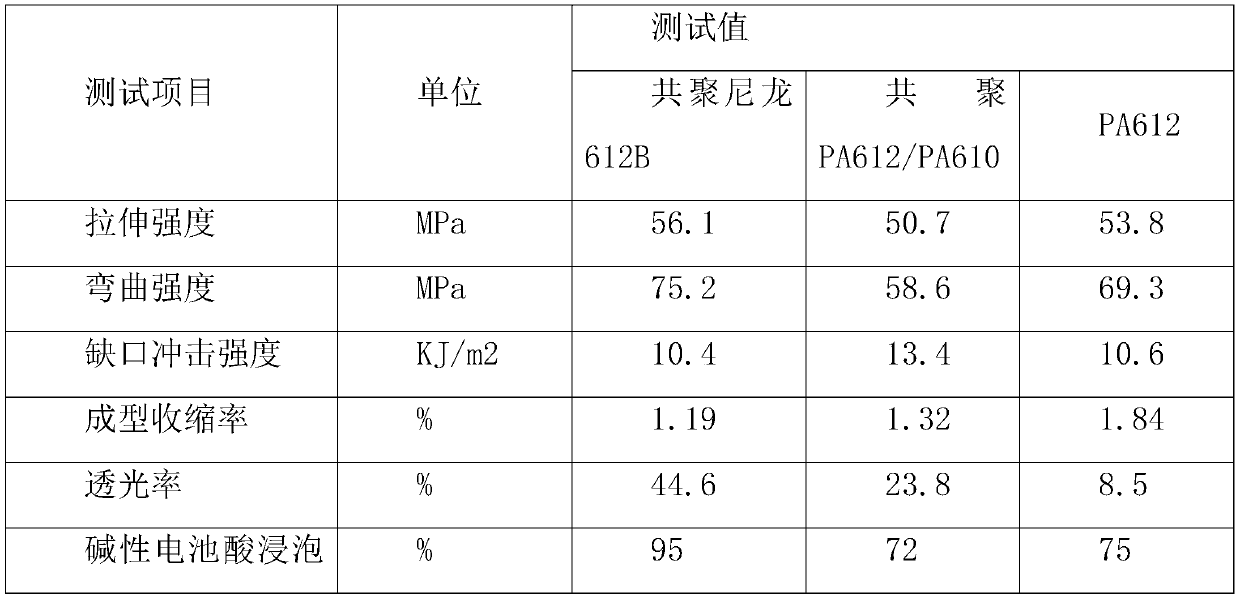

[0044] Embodiment two: the preparation of copolymerized nylon 612B

[0045] Raw materials: nylon 612 monomer: 88 parts, nylon 6I monomer 12 parts, antioxidant 0.2 parts, distilled water: 100 parts

[0046] 1. Weigh 8.8 kg of nylon 612 monomer, 1.2 kg of nylon 6I monomer, 20 grams of antioxidant, and 10 kg of distilled water into a 27L reactor, heat up to 90-105°C, start stirring, and react for 0.5 hours , continue to heat up to 205-260°C, when the pressure reaches 1.5-1.8MPa, react for 2-4 hours, then maintain the temperature at 205-260°C and exhaust to normal pressure, the reaction ends.

[0047] 2. Inject carbon dioxide or other inert gas to press the material out of the reaction kettle, cool it in a water tank, and drag it to a pelletizer for pelletizing to obtain the copolymerized nylon 612B product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com