Automobile finish paint composite coating capable of being rapidly cured and having long activation period and preparation method thereof

A composite coating and automotive topcoat technology, which is applied in coatings, pretreatment surfaces, and devices for coating liquids on surfaces, can solve problems such as fast drying speed, accelerated reaction, and shortened construction time, so as to improve drying speed , prolong the activation period, improve the effect of fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The car topcoat composite coating that can be cured quickly and has a long pot life provided by the present embodiment is an automobile topcoat composite coating composed of three kinds of paint coatings sprayed successively from bottom to top, wherein: the first One layer is a 1k base paint layer sprayed without chemical crosslinking reaction, the second layer is sprayed with a 1k transparent accelerator coating layer containing 0.5-1wt% drier without chemical crosslinking reaction, and the third layer is sprayed with chemical 2k varnish layer without driers for cross-linking reaction; 1k clear in this three-layer automotive topcoat composite coating promotes the migration of driers in the paint layer into the 2k varnish coating and contributes to the Rapid curing of the 2k varnish layer; the composite coating can be cured and polished after drying at room temperature for 1 hour, and the activation period of the 2k varnish used is not less than 6 hours, and the composit...

Embodiment 2

[0054] The fast-curing and long pot life automotive finish composite coating and preparation method thereof provided in this embodiment are basically the same as in Example 1, except that:

[0055] The 1K transparent accelerating paint is made of 20wt% main resin, 20.4wt% auxiliary resin, 55wt% solvent, 0.6wt% drier and 4wt% auxiliary agent.

[0056] The solvent therein is butyl acetate.

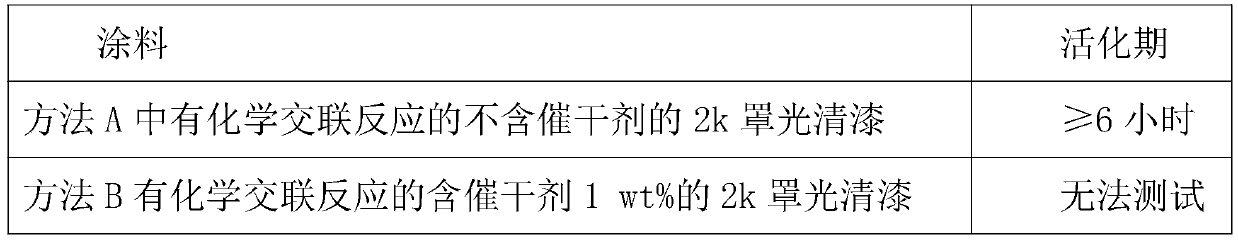

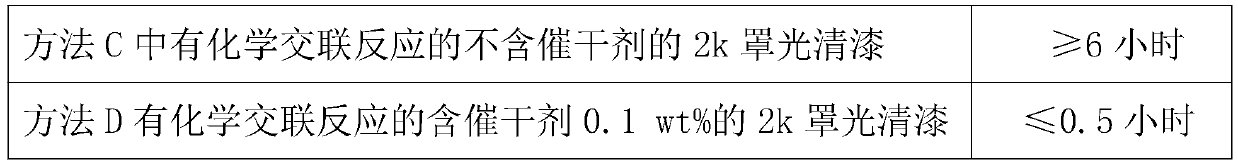

[0057] When the temperature is 8°C and the humidity is 50%RH, four methods are used for construction.

[0058] Method A: Spray 1k primer without chemical crosslinking reaction, surface dry for 10 minutes, spray 2k finish varnish with chemical crosslinking reaction without drier;

[0059] Method B: Spray a 1k primer without a chemical crosslinking reaction, let it dry for 10 minutes, and spray a 2k finish varnish with a chemical crosslinking reaction containing 0.6wt% drier;

[0060] Method C (i.e. the present invention): spray the 1k primer without chemical crosslinking reaction, surface d...

Embodiment 3

[0068] The fast curing and long pot life automotive finish composite coating provided by this embodiment and its preparation method are basically the same as those in Examples 1 and 2, except that:

[0069] The 1K transparent accelerating paint is made of 25wt% of main resin, 20wt% of auxiliary resin, 47wt% of solvent, 0.5wt% of drier and 7.5wt% of auxiliary agent.

[0070] The solvent is a mixture of ethyl 3-ethoxy propionate and methyl isobutyl ketone, prepared according to 50 wt% of each.

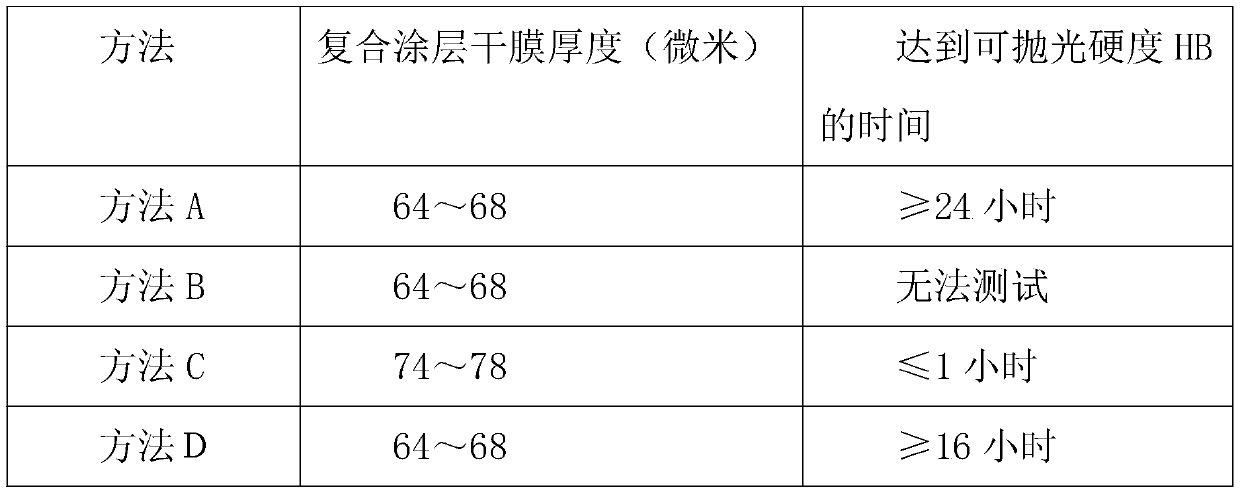

[0071] When the temperature is 25°C and the humidity is 40%RH, four methods are used for construction.

[0072] Method A: Spray a 1k primer without chemical crosslinking reaction, let it dry for 5 minutes, and then spray a 2k finish varnish with chemical crosslinking reaction without drier;

[0073] Method B: Spray a 1k primer without chemical crosslinking reaction, let it dry for 5 minutes, and spray a 2k finish varnish with chemical crosslinking reaction containing 1% drier;

[0074]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com