Method for prolonging shelf life of beer

A technology of shelf life and beer, applied in the field of beer production, can solve the problems of large investment in equipment, large equipment area, damage to beer taste and nutrients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

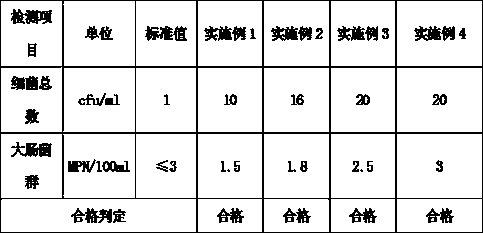

Examples

Embodiment 1

[0015] A method for prolonging the shelf life of beer, comprising steps as follows:

[0016] ⑴ Beer preparation: According to the original production process of beer, malting, saccharification, and fermentation are carried out. After fermentation, the production goes to the beer filling process, and the beer is poured into the beer barrel;

[0017] (2) Use the acid-base precipitation method to extract α-acid and β-acid from hops, and mix the two, and add 50g of the mixture of α-acid and β-acid per 1000L beer, in which α-acid and β-acid -Acids account for 40:80 by mass ratio;

[0018] (3) Mix the α-acid and β-acid with the beer evenly in the beer barrel, and store it in bottle.

Embodiment 2

[0020] A method for prolonging the shelf life of beer, comprising steps as follows:

[0021] ⑴ Beer preparation: According to the original production process of beer, malting, saccharification, and fermentation are carried out. After fermentation, the production goes to the beer filling process, and the beer is poured into the beer barrel;

[0022] (2) Use the acid-base precipitation method to extract α-acid and β-acid from hops, and mix the two, and add 50g of the mixture of α-acid and β-acid per 1000L beer, in which α-acid and β-acid -Acids account for 30:80 by mass ratio;

[0023] (3) Mix the α-acid and β-acid with the beer evenly in the beer barrel, and store it in bottle.

Embodiment 3

[0025] A method for prolonging the shelf life of beer, comprising steps as follows:

[0026] ⑴ Beer preparation: According to the original production process of beer, malting, saccharification, and fermentation are carried out. After fermentation, the production goes to the beer filling process, and the beer is poured into the beer barrel;

[0027] (2) Use the acid-base precipitation method to extract α-acid and β-acid from hops, and mix the two, and add 50g of the mixture of α-acid and β-acid per 1000L beer, in which α-acid and β-acid - The proportions of the acids in mass ratio are 35:80;

[0028] (3) Mix the α-acid and β-acid with the beer evenly in the beer barrel, and store it in bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com