A kind of production technology of silk cashmere semi-worsted yarn

A production process, cashmere technology, applied in the processing of textile materials, textile processing machine accessories, yarn, etc., can solve the problems of easy precipitation of dyes, easy breakage of semi-worsted yarns, easy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

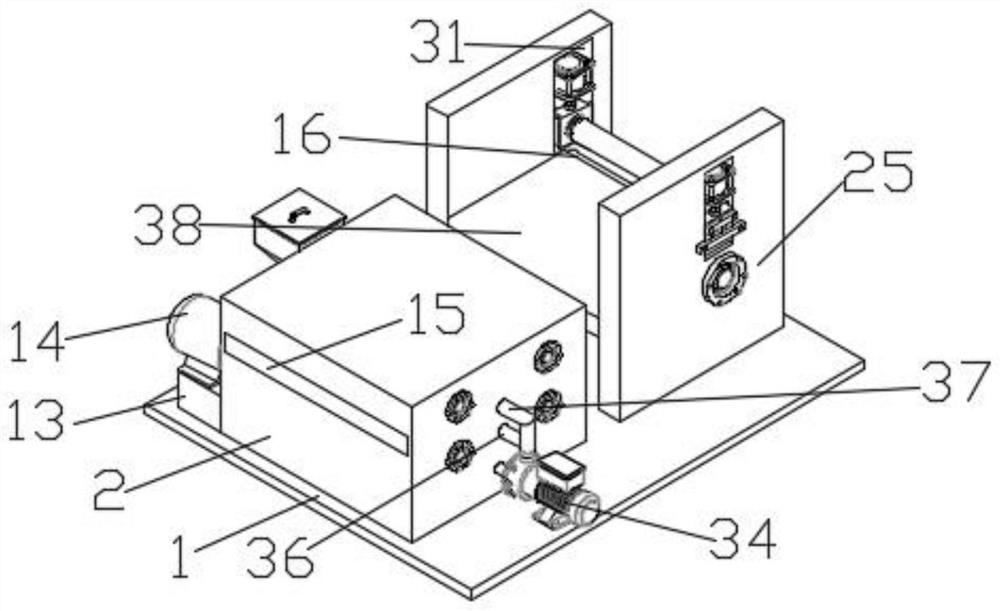

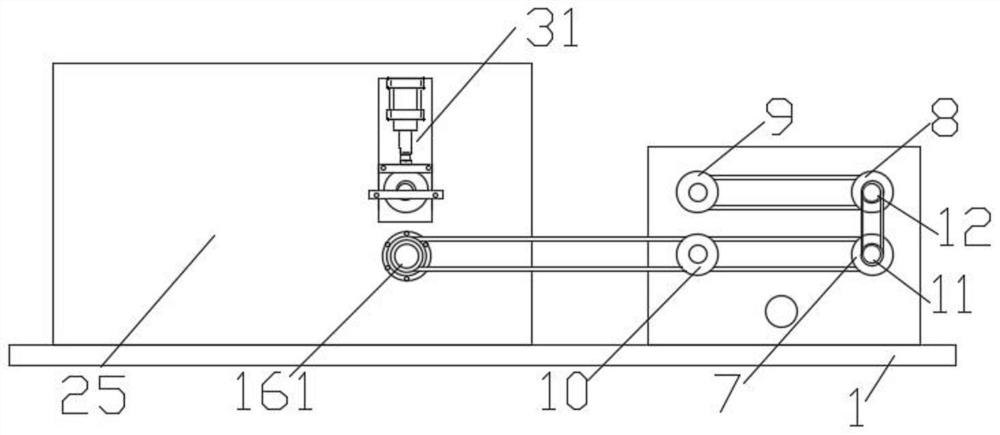

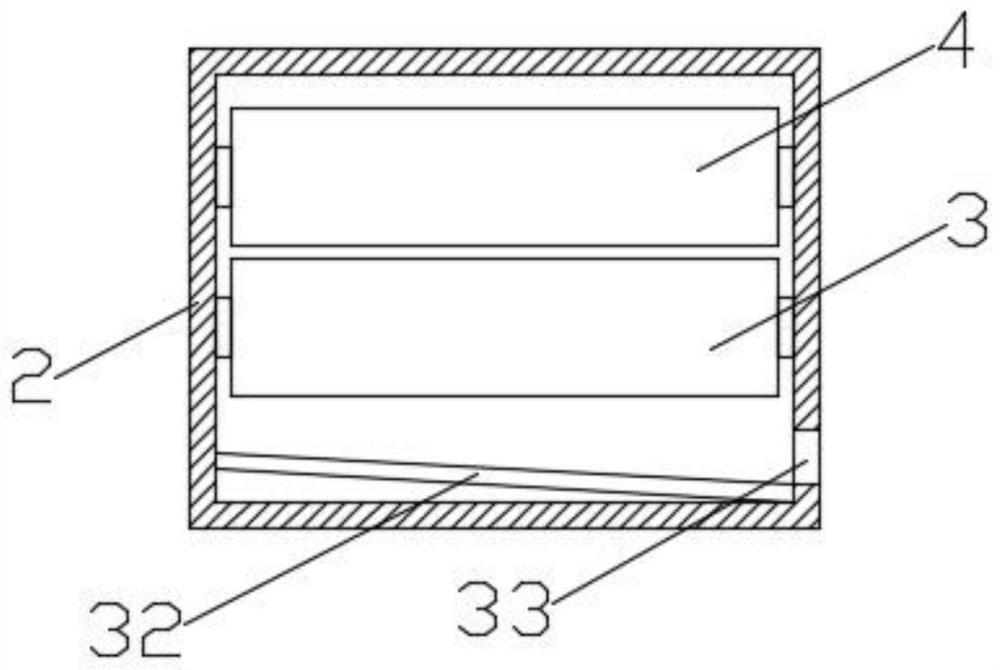

Method used

Image

Examples

Embodiment 1

[0037] A kind of production technology of silk cashmere semi-worsted yarn, comprises the following steps:

[0038] Step 1: in parts by weight, weigh 30 parts of cotton fiber, 20 parts of mercerized wool fiber, and 15 parts of cashmere fiber, add 1.5 parts of oil agent by weight to the cashmere fiber, and disperse and mix. Obtain pretreated cashmere fiber;

[0039] Step 2: adding the above-mentioned cotton fiber, mercerized wool fiber, and pretreated cashmere fiber into a wool machine for mixing to obtain a wool fiber;

[0040] Step 3: adding the above-mentioned wool fibers to the carding machine to prepare carded fibers;

[0041] Step 4: adding the above-mentioned carded fibers to a drawing frame to prepare drawn fibers;

[0042] Step 5: Put the above drawn fibers into the roving frame to prepare roving;

[0043] Step 6: Put the above-mentioned roving fiber into the spinning frame to obtain semi-finished silk cashmere semi-worsted yarn;

[0044] Step 7: Pass the above-ment...

Embodiment 2

[0048] Step 1: Take 50 parts by weight of cotton fiber, 40 parts of mercerized wool fiber and 35 parts of cashmere fiber, add 2 parts by weight of oil agent to the cashmere fiber, break up and mix, Obtain pretreated cashmere fiber; Steps 2, 3, 4, 5, 6, and 7 are all the same as in Example 1;

[0049] Specifically, the oil agent is prepared from the following raw materials in parts by weight: 0.7 part of antistatic agent, 0.8 part of crude oil, and 0.15 part of silica sol. The mercerized wool fiber is prepared by the following method: (1) placing the wool in a scouring liquid, washing it at a constant temperature of 35°C, and drying it at 90°C after washing; (2) putting the dried wool into 35ml of 30% hydrogen peroxide / L, sodium pyrophosphate 1.3g / L, pH 7.5 mixed solution, temperature 45°C, bath ratio 1:30 for 40min; (3) Add protease to the treated wool, the amount of protease added is 4% , the treatment temperature is 60°C, and the treatment time is 60min; (4) adding deoxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com