Concrete pavement construction method

A technology of concrete pavement and construction method, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of cracking, breaking, the road surface is no longer smooth, and the vehicle rolls over, etc. Excellent, high structural stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

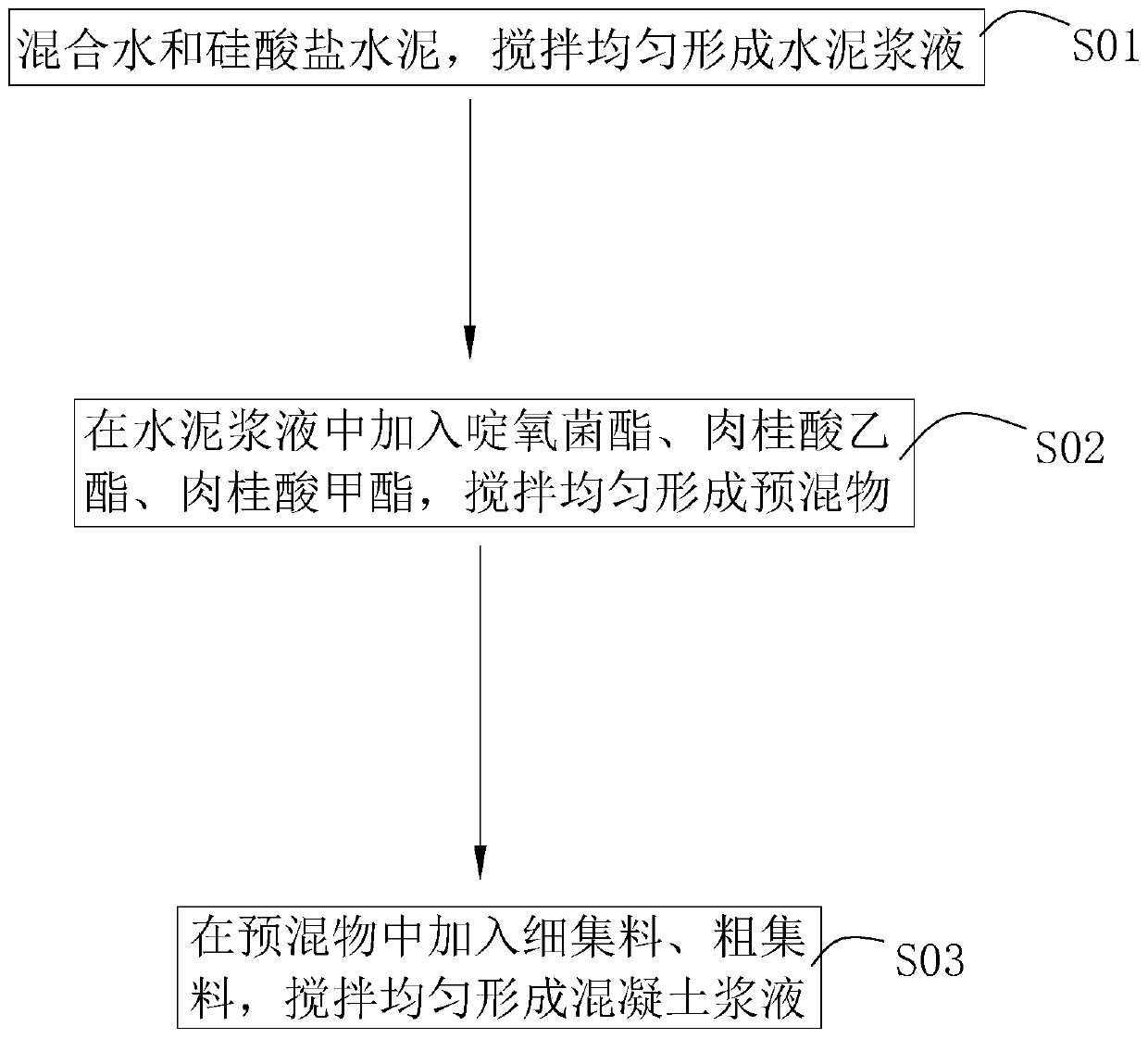

[0075] refer to figure 1 , a concrete slurry, the preparation method of the concrete slurry is as follows:

[0076] S01. Add 100kg of Portland cement, 90kg of water, and 11kg of water reducing agent into the stirring tank at a rotating speed of 90r / min, and stir for 3min to form cement slurry;

[0077] S02. Add 25 kg of picoxystrobin, 2 kg of ethyl cinnamate, and 2 kg of methyl cinnamate to the cement slurry, and stir at a speed of 60 r / min for 8 min to form a premix;

[0078] S03. Add 250kg of fine aggregate and 300kg of coarse aggregate to the premix at a speed of 45r / min, and stir for 10 minutes to form a concrete slurry at a speed of 20r / min, and continue stirring until it is used up.

Embodiment 2

[0080] refer to figure 1 , a concrete slurry, the preparation method of the concrete slurry is as follows:

[0081] S01. Add 100kg of Portland cement, 100kg of water, and 10kg of water reducing agent into the stirring tank at a rotating speed of 90r / min, and stir for 3min to form cement slurry;

[0082] S02. Add 27.5kg of picoxystrobin, 2.5kg of ethyl cinnamate, and 2.5kg of methyl cinnamate to the cement slurry, and stir at a speed of 60r / min for 8min to form a premix;

[0083] S03. Add 275kg of fine aggregate and 325kg of coarse aggregate to the premix at a speed of 45r / min, and stir for 10 minutes to form a concrete slurry at a speed of 20r / min, and continue stirring until it is used up.

Embodiment 3

[0085] refer to figure 1 , a concrete slurry, the preparation method of the concrete slurry is as follows:

[0086] S01. Add 100kg of Portland cement, 110kg of water, and 9kg of water reducing agent into the stirring tank at a rotating speed of 90r / min, and stir for 3min to form cement slurry;

[0087] S02. Add 30 kg of picoxystrobin, 3 kg of ethyl cinnamate, and 3 kg of methyl cinnamate to the cement slurry at a speed of 60 r / min and stir for 8 min to form a premix;

[0088] S03. Add 300kg of fine aggregate and 350kg of coarse aggregate to the premix at a speed of 45r / min, and stir for 10 minutes to form a concrete slurry at a speed of 20r / min, and continue stirring until it is used up.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com