Underwater anti-sliding cast-in-situ bored pile foundation and construction method thereof

A technology of bored piles and foundations, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., and can solve the problems of soil shear strength reduction, underwater bored pile foundation slippage, effective stress reduction, etc. problem, achieve the effect of enhancing shear strength, improving installation efficiency and reducing penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

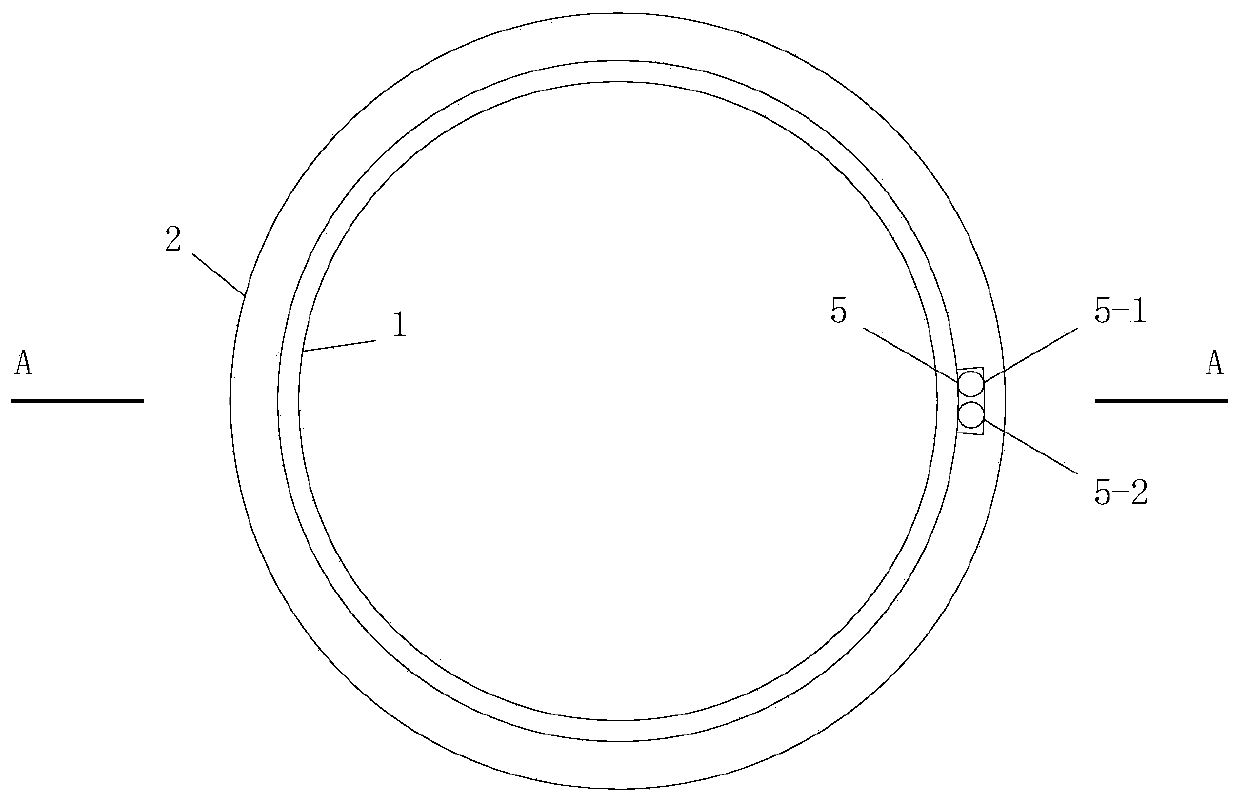

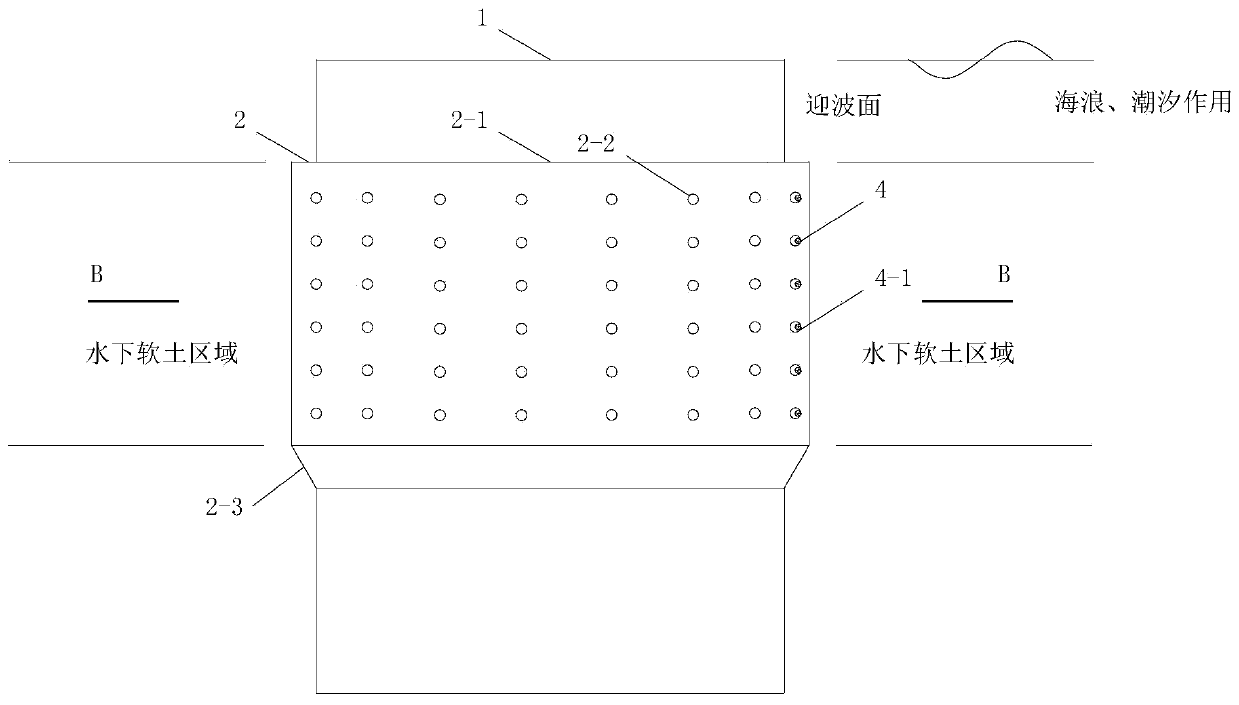

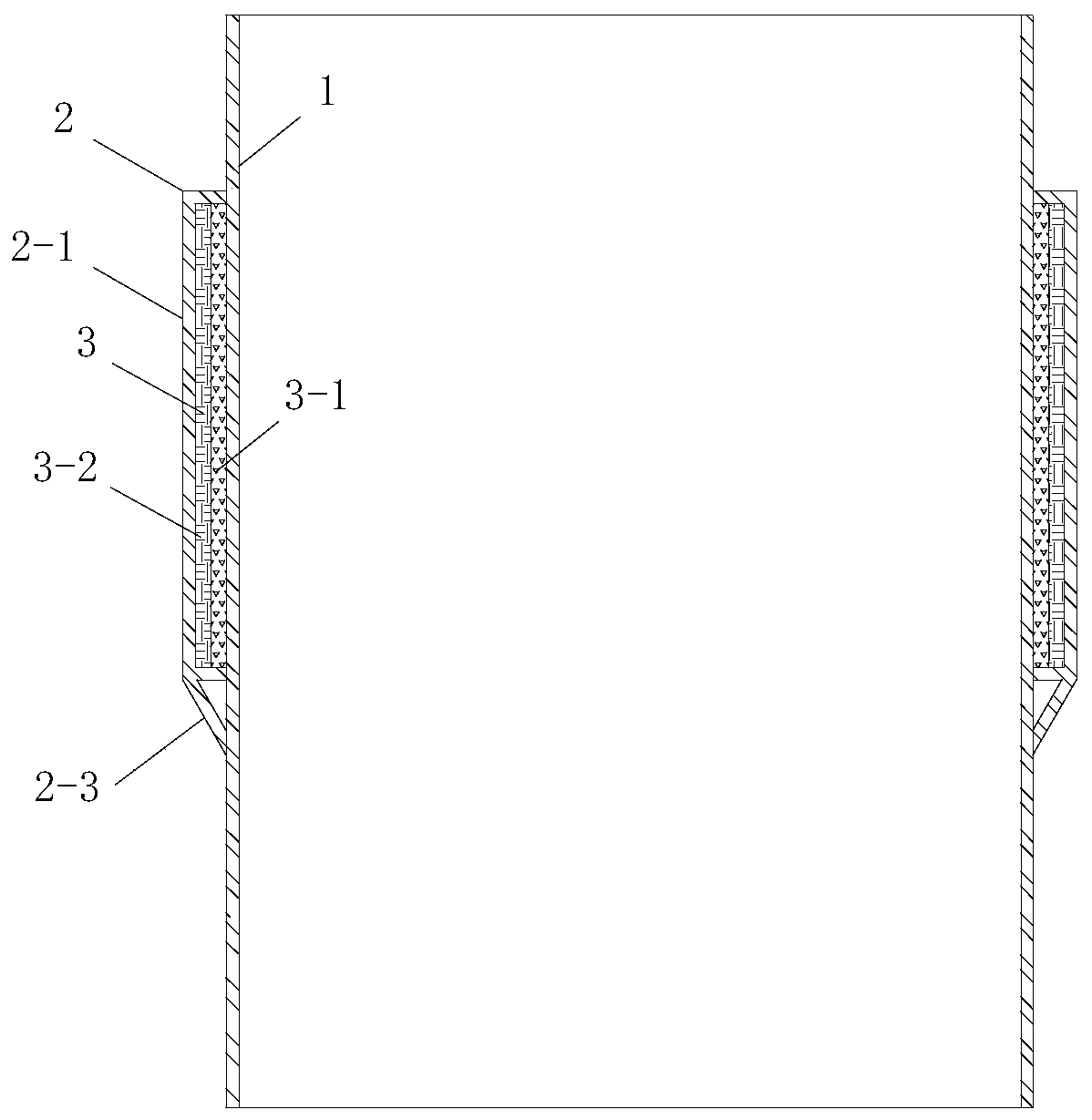

[0056] The underwater anti-skid bored pile foundation provided in this embodiment is used in the underwater soft soil slopes on river alluvial plains, river estuaries and continental shelves. Such as Figure 1-4 As shown, the underwater anti-skid bored pile foundation is formed by sealing and connecting at least one section of new steel casing and at least one section of ordinary steel casing 6 in turn from bottom to top; the new type steel casing and ordinary steel casing The reinforced cage 7 is placed in the 6 and the concrete 8 is poured; the ordinary steel casing 6, the reinforced cage 7 and the concrete 8 constitute the main body of the bored pile;

[0057] The novel steel casing includes an inner cylinder 1, an outer cylinder 2, a cavity 3 between the inner cylinder and the outer cylinder, and an automatic pore pressure adjustment syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com