Automatic cement applying machine for outdoor ceramic tile adhering

A smearing machine and ceramic tile technology, which is applied in the direction of construction and building construction, can solve the problems of hand fatigue, cumbersome operation, low efficiency, etc., and achieve the effect of ensuring the effect of smearing, fast feeding and discharging, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

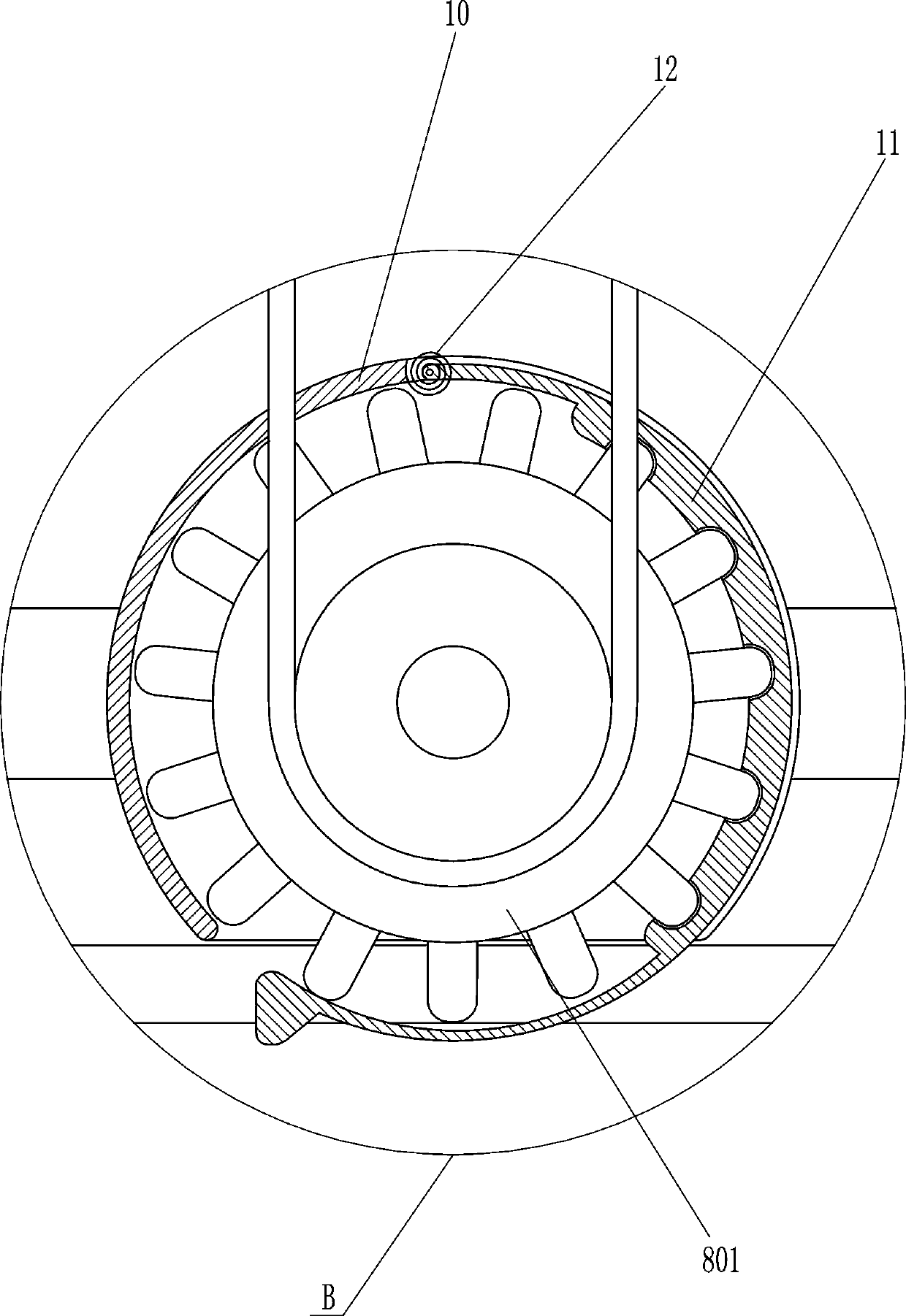

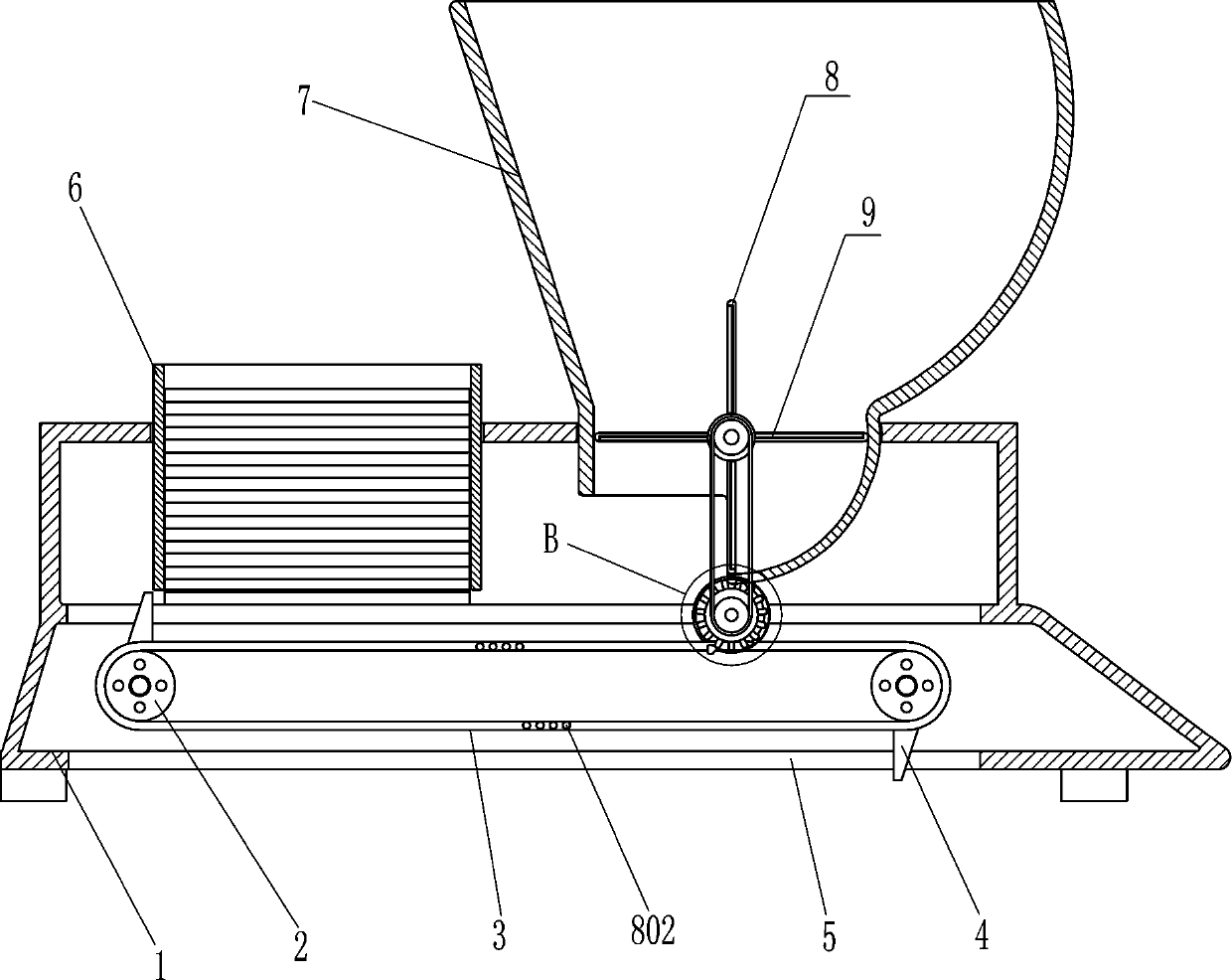

[0017] A cement automatic applicator for outdoor tile bonding, such as figure 1 As shown, it includes a housing 1, an electric sprocket 2 and a chain 3. The electric sprockets 2 are arranged on the lower parts of the left and right sides of the housing 1, and the electric sprockets 2 on both sides are symmetrically arranged on the left and right. A chain 3 is connected, and also includes a conical push block 4, a blanking frame 6, a hopper 7 and a blanking mechanism 8. The upper and lower sides of the surface of the chain 3 are connected with a conical push block 4, and the conical push block 4 is connected by bolts. The way is connected with the chain 3, the middle part and the bottom of the housing 1 are provided with a through groove 5 for the passage of the conical push block 4, and the left side of the housing 1 is provided with a blanking frame 6, the shape of the blanking frame 6 is Cuboid, between the bottom of the blanking frame 6 and the through groove 5 in the middl...

Embodiment 2

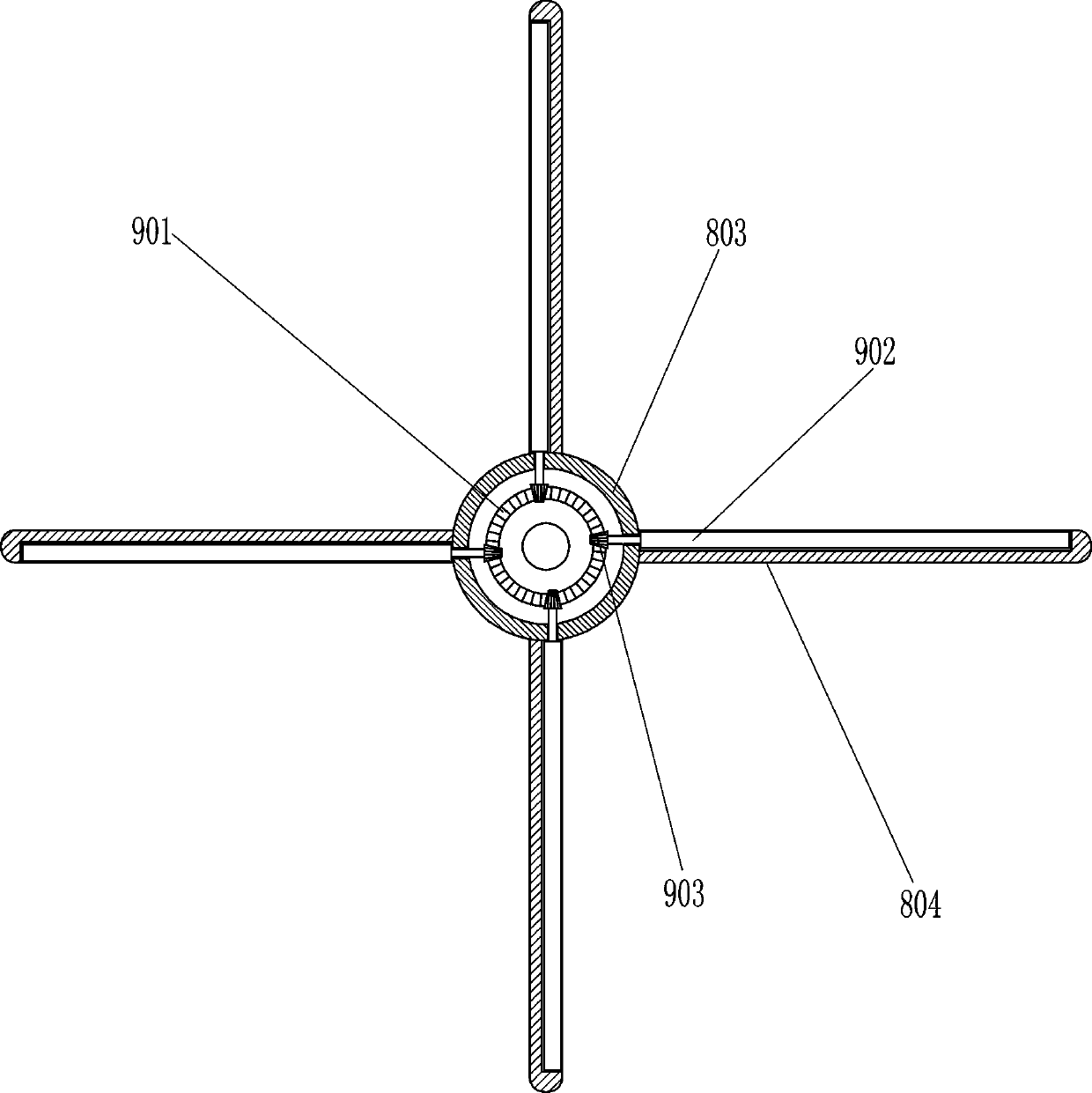

[0022] Such as figure 2 As shown, a scraper assembly 9 is also included, and the scraper assembly 9 includes a first bevel gear 901, a roller shaft 902 and a second bevel gear 903, and 4 sets of second cones are evenly spaced on the side wall of the hollow shaft sleeve 803. The number of gears 903, each group of second bevel gears 903 is 6, and the 6 second bevel gears 903 are evenly distributed along the axial direction of the hollow shaft sleeve 803, and the second bevel gears 903 are connected with the hollow shaft sleeve 803 through bearing seats Rotational connection, each baffle plate 804 is rotationally connected with 6 roller shafts 902, the roller shafts 902 are connected with the second bevel gear 903, and the hollow shaft sleeve 803 is provided with 6 first bevel gears 901, 6 The first bevel gears 901 are evenly distributed along the axial direction of the hollow shaft sleeve 803 , and the six first bevel gears 901 are connected by rotating shafts fixed on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com