Radar level meter

A radar level gauge and support plate technology, which is applied in liquid/fluid solid measurement, engine lubrication, electric vehicles, etc., can solve the problems affecting the accuracy of radar level gauge measurement results, loss of radar level gauge, and lack of protective structures. and other problems, to achieve the effect of convenient installation and disassembly, delaying rust, and avoiding sun exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

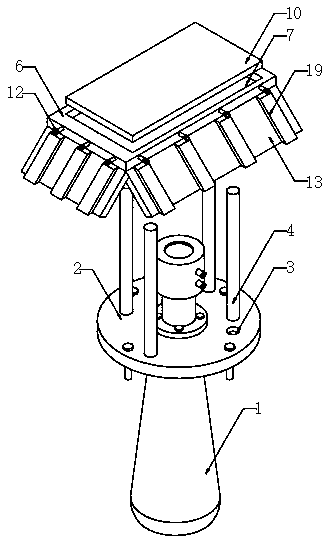

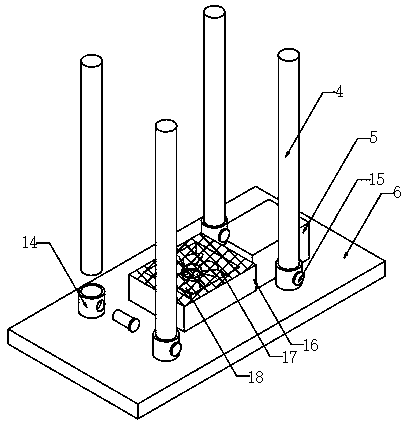

[0023] Such as Figure 1-Figure 3 As shown, a radar level gauge includes a radar level gauge body 1, a mounting flange 2 is fixed in the middle of the radar level gauge body 1, and a plurality of mounting holes 3 are opened on the top of the mounting flange 2, and a plurality of The mounting holes 3 are threadedly connected to the bottoms of the corresponding vertical rods 4 respectively, and the tops of a plurality of vertical rods 4 are engaged with the corresponding sleeves 14 respectively. The top of the tube 14 is fixedly connected to the four corners of the bottom end of the support plate 6 respectively, the vertical rod 4 is screwed into the inside of the mounting hole 3, the sleeve 14 at the bottom end of the support plate 6 is aligned with the vertical rod 4 and then put down, so that the vertical rod 4 The rod 4 is snapped into the sleeve 14, and then inserted into the pin shaft 15 to complete the installation of the support plate 6. The operation is simple and conve...

Embodiment 2

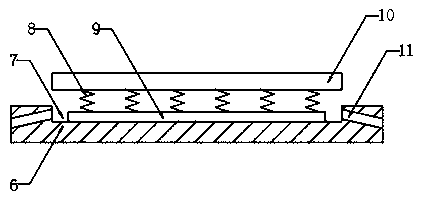

[0025] On the basis of Embodiment 1, such as figure 1 with figure 2 As shown, the protective structure includes a groove 7 set in the middle of the top of the support plate 6, the middle of the top of the groove 7 is fixedly provided with a boss 9, and the top of the boss 9 is fixed with a plurality of compression springs 8, and the plurality of compression springs The tops of 8 are fixedly connected with the bottom of the top plate 10. When a foreign object falls on the top plate 10, the top plate 10 is impacted and falls, and squeezes the compression spring 8. The compression spring 8 compresses the top plate 10 in the process of restoring deformation. Jacking up can bounce foreign matter away to avoid accumulation on the top plate 10 and cause excessive pressure on the top plate 10. The top of the support plate 6 is provided with a plurality of drainage chutes 11, and one end of the drainage chute 11 is fixedly communicated with the groove 7 , the other end of the drain c...

Embodiment 3

[0027] On the basis of embodiment one and embodiment two, such as figure 1 with image 3 As shown, light baffles 13 are fixedly installed on the edge of the support plate 6, and a plurality of solar photovoltaic panels 19 are fixedly installed on one side of the four light baffles 13. The light baffles 13 can block sunlight and avoid radar level gauges. The main body 1 is exposed to the sun, while the solar photovoltaic panel 19 absorbs solar energy and converts it into electrical energy. The middle part of the bottom end of the support plate 6 is fixed with a fan base 16, and the middle part of the bottom end of the fan base 16 is provided with a mounting groove 17. The inside of the mounting groove 17 is fixed and installed There is a fan 18, and the bottom of the fan base 16 is fixedly provided with a protective screen. On the one hand, the wind blown by the fan 18 can clean the surface of the radar level gauge body 1, sweep the dust on the radar level gauge body 1, and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com