Cylinder body surface wireless temperature measurement and detection system

A wireless temperature and detection system technology, which is applied in the field of temperature measurement, can solve problems such as structural design defects and high temperature, and achieve the effects of reliable temperature detection, improved accuracy, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

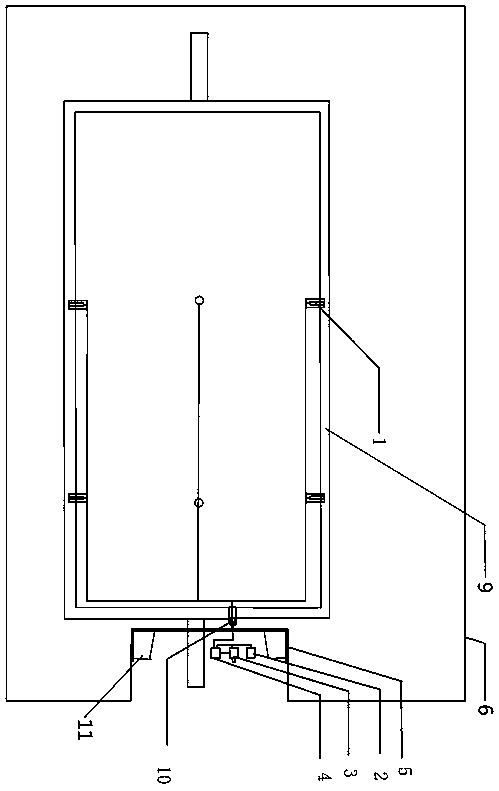

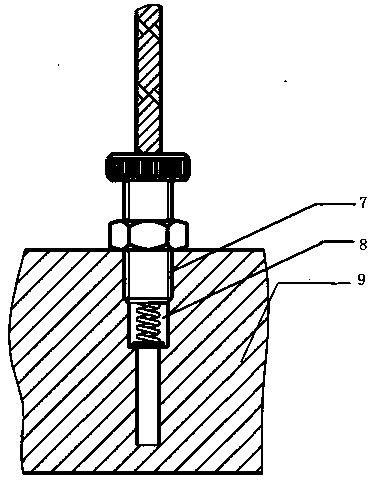

[0026] Such as figure 1 Shown is a wireless temperature measurement and detection system on the surface of a cylinder body 9, including a cylinder body 9, a temperature sensor 1, a power module and a signal processing unit, and a heat insulation unit. The sensor 1 is placed in the installation hole 7, the heat insulation unit is arranged outside the cylinder body 9, the signal processing unit is connected to the temperature sensor 1, the power module and the signal processing unit are arranged outside the cylinder body 9 and separated from the cylinder body 9 by the heat insulation unit . In order to detect the temperature of the side wall of the cylinder body 9, a temperature sensor 1 needs to be installed, but there are high-temperature substances in the cylinder body 9 during operation, which causes the temperature of the cylinder body 9 itself to be high, exceeding the normal operating temperature of the electronic components, so only the temperature The sensor 1 is kept ...

Embodiment 2

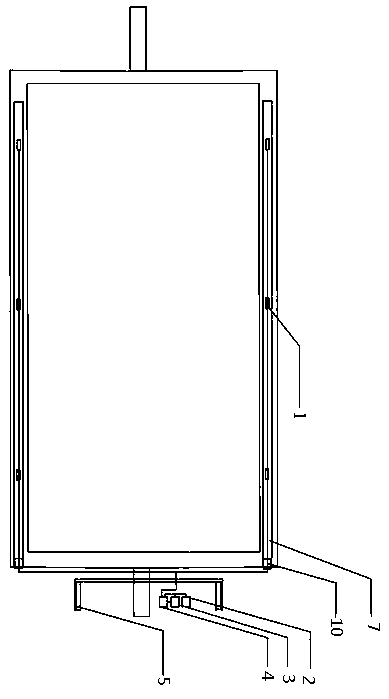

[0035] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the installation hole 7 is parallel to the central axis of the cylinder body 9, a plurality of temperature sensors 1 are arranged in the installation hole 7, and the installation hole 7 is filled with a heat-conducting medium, and the temperature sensor 1 and the signal The processing unit is connected through a sealed cable, and the outlet of the installation hole 7 is sealed. Different from the previous solution, this method is easy to disassemble and maintain the temperature sensor 1. In addition, due to the difference in temperature at different parts of the cylinder body 9, the elongated installation hole 7 parallel to the central axis of the cylinder body 9 and the heat transfer medium can be used. The temperature detected by the temperature sensor 1 is more accurate, and at the same time, the heat transfer medium can prevent the change of the contact surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com