A kind of preparation method and product thereof of water-based polyurethane textile finishing agent doped in situ with nano-silver

A water-based polyurethane and textile finishing technology, applied in textiles and papermaking, fiber treatment, abrasion-resistant fibers, etc., can solve the problems of poor film formation, poor hydrophilicity of chitosan, hard hand feeling, etc., and improve the antibacterial effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

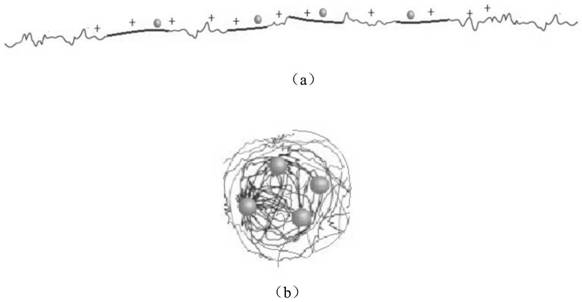

Image

Examples

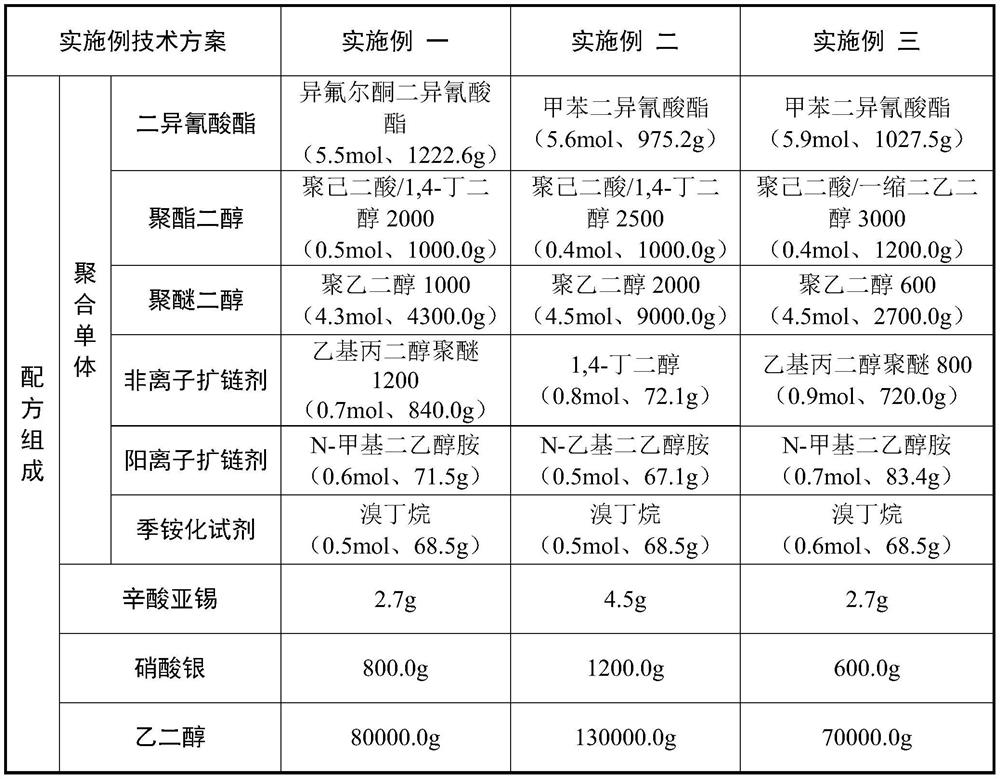

Embodiment 1

[0054] Embodiment 1 The preparation method of the water-based polyurethane textile finishing agent doped in situ with nano-silver of the present invention

[0055] The concrete steps of this preparation method:

[0056] (1) The step of polyurethane dispersion preparation, this step reacts polyester diol, polyether diol and diisocyanate, nonionic chain extender, cationic chain extender, quaternizing agent, stannous octoate, and then Glycol is dispersion medium, makes polyurethane dispersion liquid; Specifically:

[0057] (1.1) drop into polyester diol, the polyether diol of total amount 70%, the nonionic chain extender of total amount 60% in reactor;

[0058] (1.2) Heat up to 75°C, add diisocyanate and react under stirring for 30min;

[0059] (1.3) Add stannous octoate, heat up to 85-90°C and react for 120min under stirring;

[0060] (1.4) Cool down to 45°C, add the cationic chain extender dropwise evenly within 15 minutes, control the temperature at 50-55°C after the droppi...

Embodiment 2

[0070] Embodiment 2 The preparation method of the water-based polyurethane textile finishing agent doped with nano-silver in situ of the present invention

[0071] The concrete steps of this preparation method:

[0072] (1) The step of polyurethane dispersion preparation, this step reacts polyester diol, polyether diol and diisocyanate, nonionic chain extender, cationic chain extender, quaternizing agent, stannous octoate, and then Glycol is dispersion medium, makes polyurethane dispersion liquid; Specifically:

[0073] (1.1) drop into polyester diol, the polyether diol of total amount 75%, the nonionic chain extender of total amount 60% in reactor;

[0074] (1.2) Heat up to 70°C, add diisocyanate and react for 40min under stirring;

[0075] (1.3) Add stannous octoate, heat up to 80-85°C and react for 100min under stirring;

[0076] (1.4) Cool down to 45°C, add cationic chain extender evenly dropwise within 10 minutes, control the temperature at 55±5°C and react under stirr...

Embodiment 3

[0086] Embodiment 3 The preparation method of the water-based polyurethane textile finishing agent doped in situ with nano-silver of the present invention

[0087] The concrete steps of this preparation method:

[0088] (1) The step of polyurethane dispersion preparation, this step reacts polyester diol, polyether diol and diisocyanate, nonionic chain extender, cationic chain extender, quaternizing agent, stannous octoate, and then Glycol is dispersion medium, makes polyurethane dispersion liquid; Specifically:

[0089](1.1) drop into polyester diol, the polyether diol of total amount 65%, the nonionic chain extender of total amount 50% in reactor;

[0090] (1.2) Heat up to 70°C, add diisocyanate and react for 40min under stirring;

[0091] (1.3) Add stannous octoate, heat up to 80-85°C and react for 150min under stirring;

[0092] (1.4) Cool down to 50°C, add cationic chain extender evenly dropwise within 15 minutes, control the temperature at 55±5°C after dropping, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com