A Gasket Type Pressure Sensor Used to Detect Bolt Pretightening Force

A bolt pre-tightening force and pressure sensor technology, applied in the direction of measuring force, torque/torsional force during tightening, instruments, etc. Unreliable and other problems, to achieve the effect of real-time detection of bolt pre-tightening force, compact structure, and increase of total electrical capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

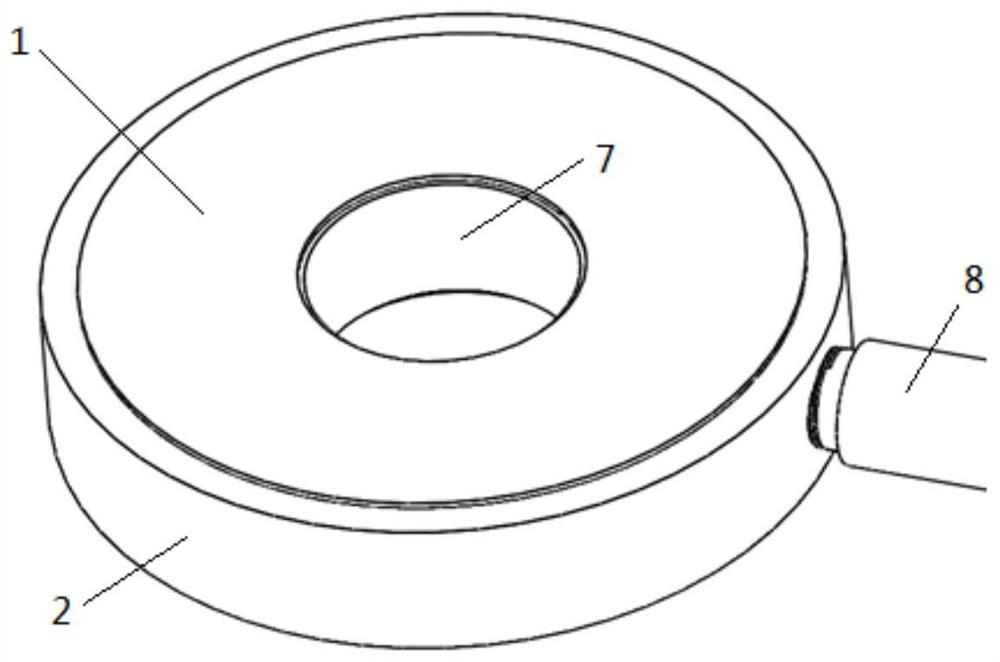

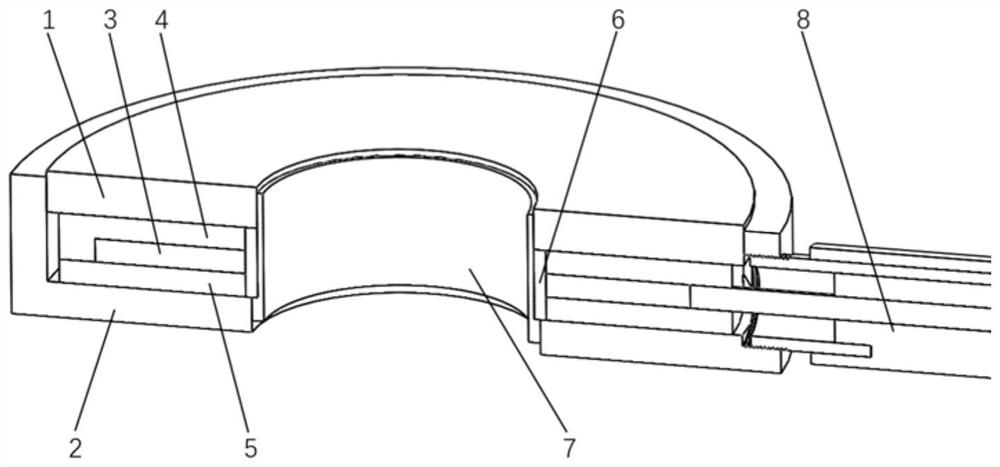

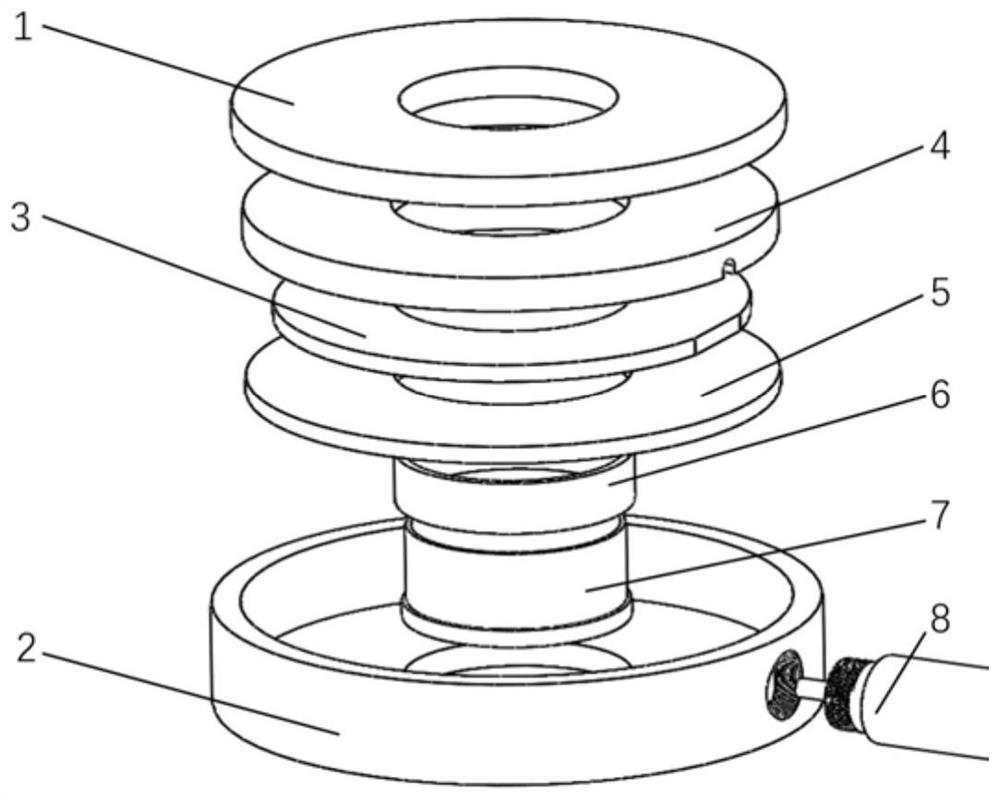

[0025] Such as Figure 1 ~ Figure 3 As shown, a gasket-type pressure sensor for detecting the pre-tightening force of bolts includes an upper cover 1, a housing 2, an upper plate 3, a first elastic body 4, a second elastic body 5, an isolation ring 6, an inner ring 7 and signal connector 8.

[0026] Wherein, the upper cover 1 is embedded in the top of the casing 2, that is, the outer diameter of the upper cover 1 is equal to the inner diameter of the casing 2, and the diameters of the two match, and can cover the upper pole plate 3 and the first elastic body after being aligned with each other. 4 and the second elastic body 5, the upper cover 1 and the casing 2 are made of carbon steel, which can ground the circuit when connected with the fastener, and the upper cover 1 and the casing 2 together form the lower plate;

[0027] There is a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com