Mining engineering vehicle lightweight model acquisition method and device

A lightweight model and vehicle model technology, which is applied in the field of obtaining lightweight models for mining engineering vehicles, can solve the problems that the accuracy cannot meet the requirements, the three-dimensional size gap is large, and the computing resource consumption is large, so as to avoid the lack of model parameters and improve the accuracy. to avoid the effects of insufficient precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

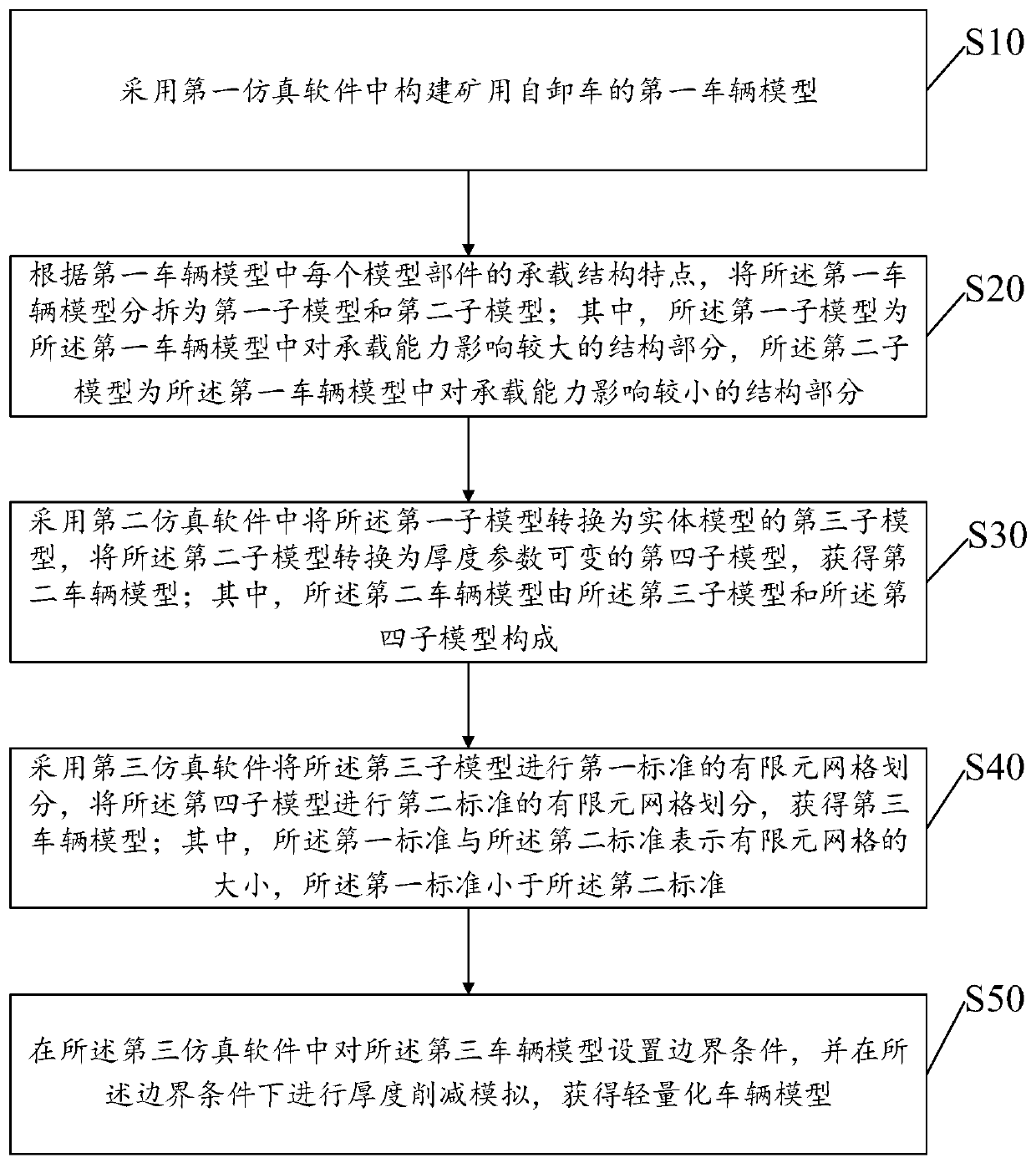

[0035] See figure 1 , figure 1 A method for acquiring a lightweight model of an engineering vehicle provided by the first embodiment of the present invention is shown, and the method includes:

[0036] Step S10: using the first simulation software to construct the first vehicle model of the mining dump truck;

[0037] Step S20: Split the first vehicle model into a first sub-model and a second sub-model according to the bearing structure characteristics of each model component in the first vehicle model; wherein, the first sub-model is the first sub-model A structural part in the vehicle model that has a greater impact on the bearing capacity, the second sub-model is a structural part in the first vehicle model that has a lesser impact on the bearing capacity;

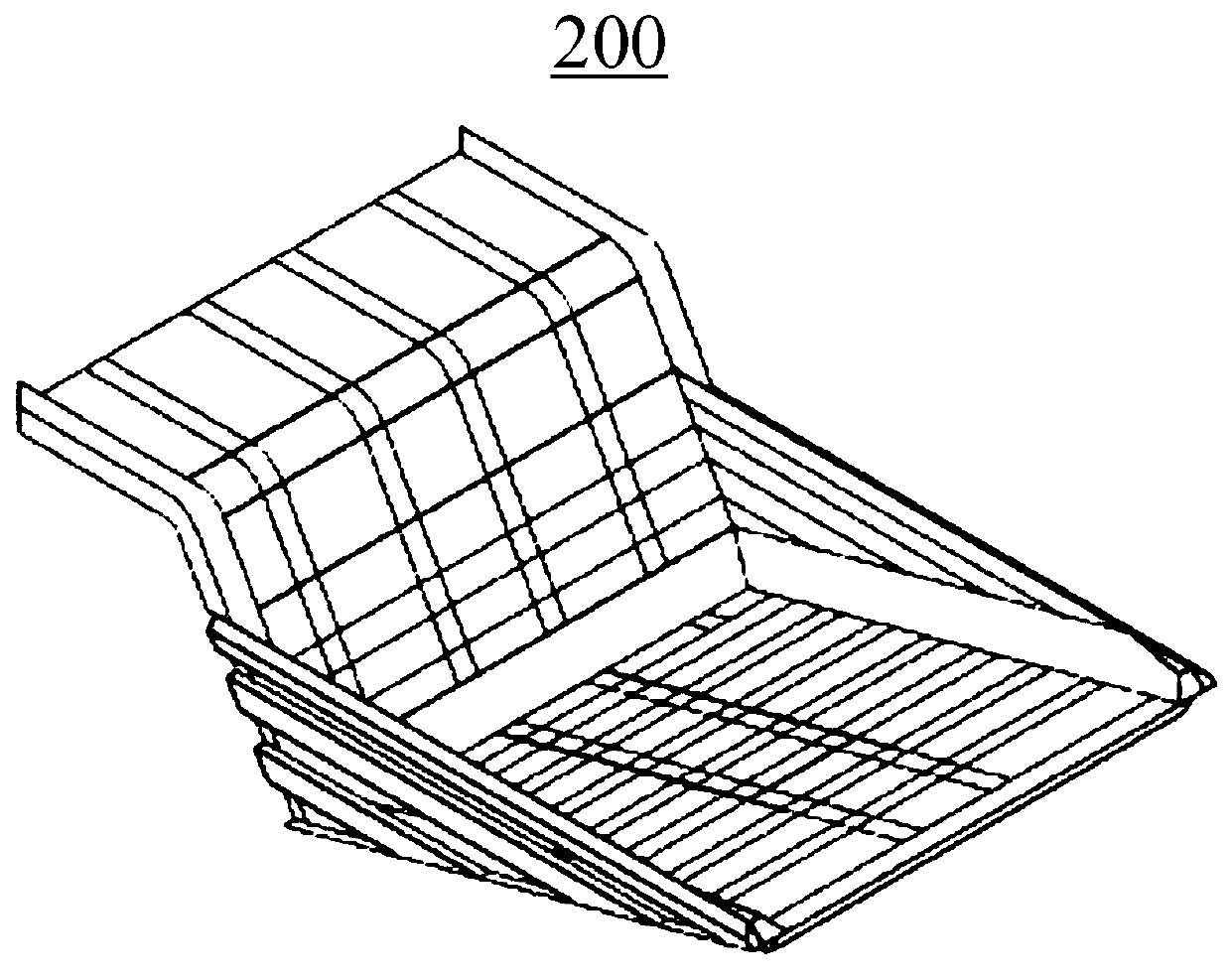

[0038] Step S30: Using the third sub-model in the second simulation software that converts the first sub-model into a solid model, converts the second sub-model into a fourth sub-model with variable thickness paramete...

Embodiment approach

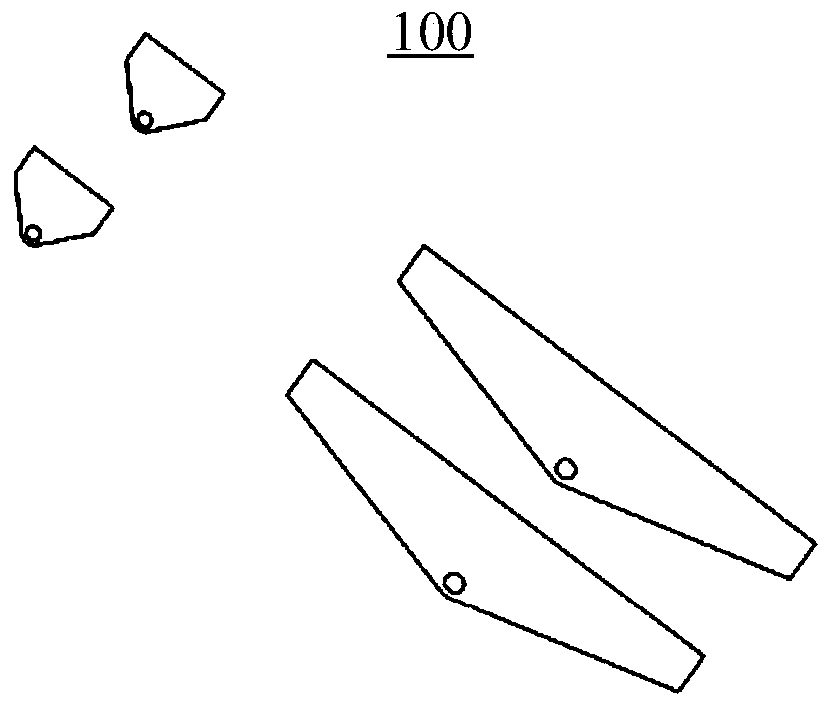

[0053] Step S31: Thickening the curved three-dimensional model of the first sub-model to obtain a third sub-model. Wherein, after stretching the thickness of the surface three-dimensional model of the first sub-model, a solid three-dimensional model, that is, the third sub-model is generated. Such as Figure 4 Shown is a solid three-dimensional model 100a representing a bottom connector.

[0054] Step S32: Group the model components in the second sub-model based on thickness to obtain a component group; wherein, model components with the same thickness in the component group are one group. The thickness parameters of each model part can be adjusted more efficiently by grouping, that is, the thickness parameters of each group can be adjusted correspondingly to the thickness parameters of each model part in the group.

[0055] Step S33: Setting variable thickness parameters for each group of model components in the component group to obtain a fourth sub-model. Specifically, u...

no. 2 example

[0077] see Figure 5 , based on the same inventive concept, this embodiment provides an engineering vehicle lightweight model acquisition device 300, the device 300 includes:

[0078] The model construction module 301 is used to construct the first vehicle model of the mining dump truck in the first simulation software; the model split module 302 is used to convert the described The first vehicle model is split into a first sub-model and a second sub-model; wherein, the first sub-model is a structural part of the first vehicle model that has a greater impact on the carrying capacity, and the second sub-model is The structural part in the first vehicle model that has little influence on the bearing capacity; the model conversion module 303 is used to convert the first sub-model into the third sub-model of the solid model in the second simulation software, and convert the The second sub-model is converted into a fourth sub-model with variable thickness parameters to obtain a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com