Device for producing and distributing nitrogen, in particular for liquefied gas carrier

A liquid gas and nitrogen technology, applied in refrigeration and liquefaction, specific gas purification/separation, liquefaction, etc., can solve problems such as unsuitable buffer tank and nitrogen generator cycle operation, frequent maintenance operations, and shortened generator service life , to achieve a stable and continuous effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0137] In the following description, the terms "upstream" and "downstream" refer to the flow of a fluid, such as a gas or a liquid, in a pipe or circuit.

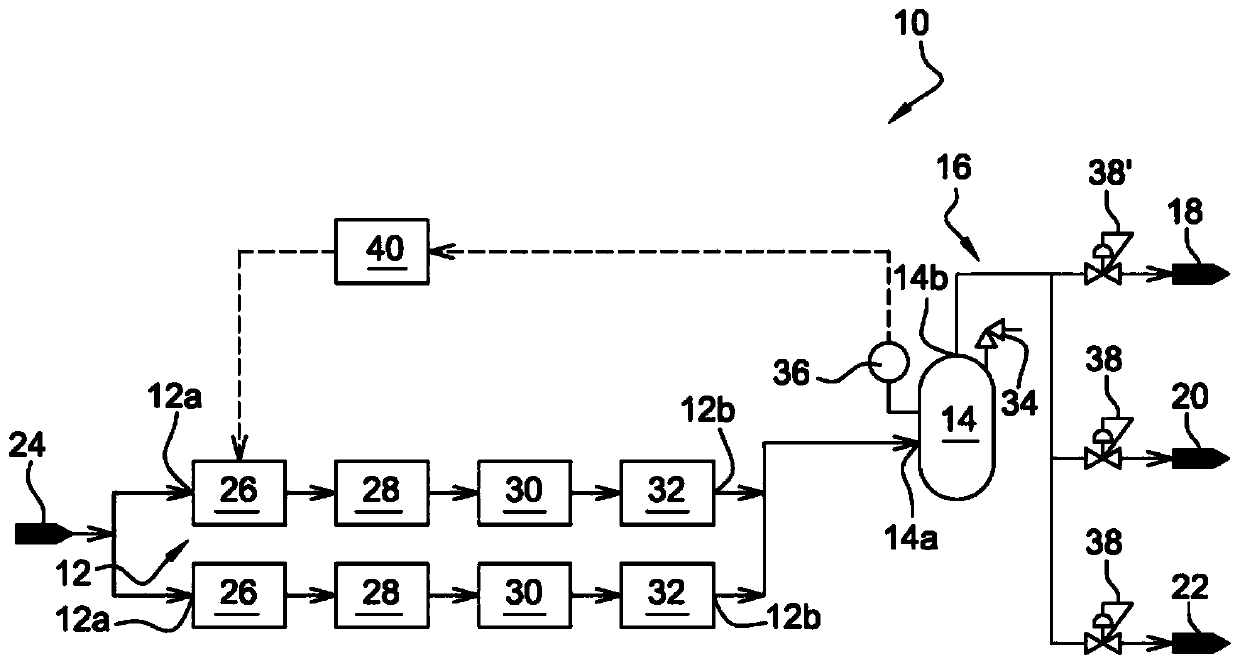

[0138] figure 1 Shown is a device 10 for generating and distributing nitrogen, in particular for liquid gas transport ships.

[0139] The device 10 basically comprises nitrogen generators 12, each nitrogen generator comprising: an air inlet 12a and a nitrogen outlet 12b; a buffer tank 14 for storing nitrogen; and a distribution device 16 for distributing nitrogen, which is designed to supply The consumers 18, 20 and 22 are supplied with nitrogen.

[0140] There are two generators 12, mounted in parallel, with their inlets 12a connected together and to a single port 24 for supplying air to the generators. Their outlets 12b are connected together by a manifold and to an inlet 14a of a surge tank 14 .

[0141] From upstream to downstream, i.e. from inlet 12a to outlet 12b, each generator 12 includes an air compressor 26, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com