Environment-friendly waste gas treatment device

A waste gas treatment device, an environmentally friendly technology, applied in the direction of gas treatment, combined devices, membrane technology, etc., can solve the problems of building waste gas treatment devices, achieve the effect of improving speed and efficiency, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Treatment methods for organic industrial waste gas

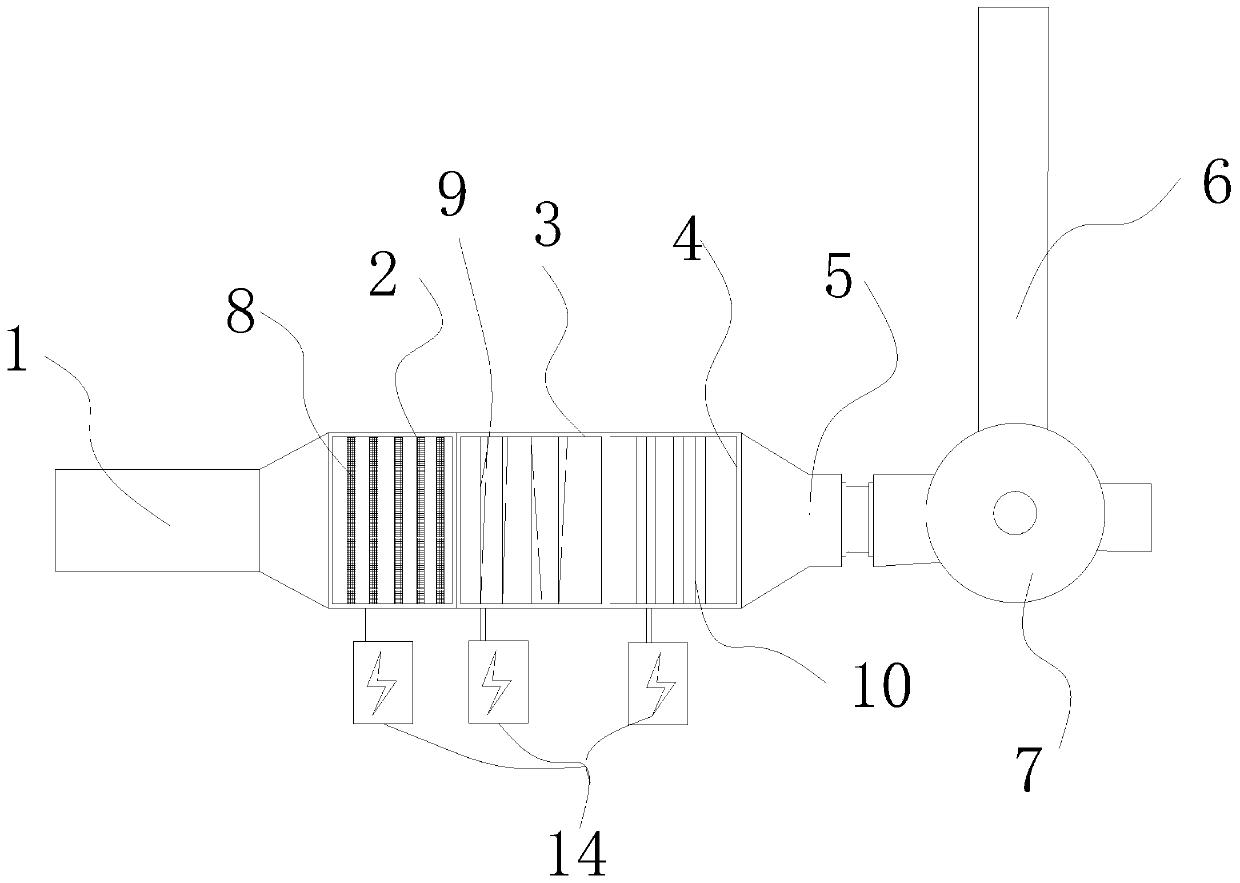

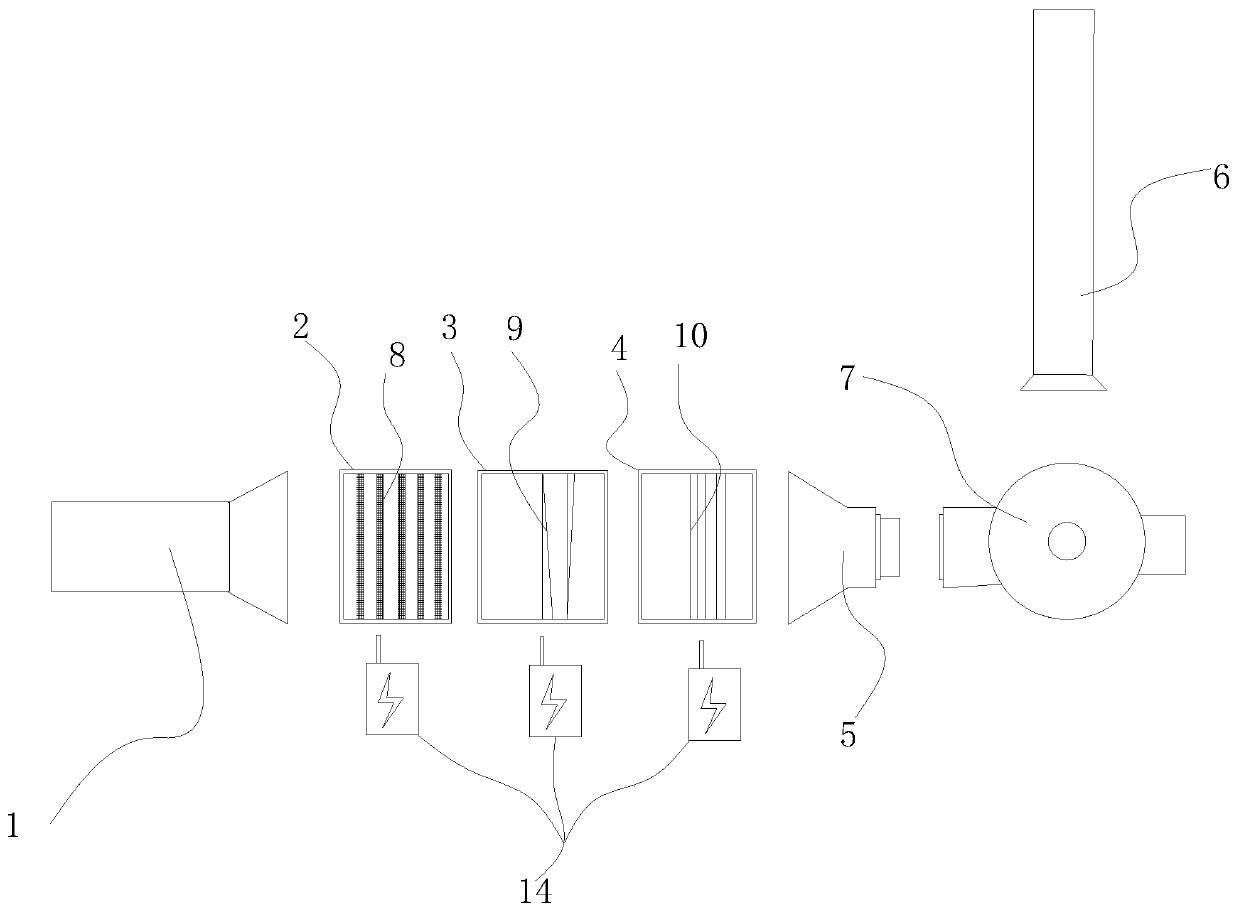

[0032] Open the door of each treatment box, and the adsorbate filling box 8, heating lamp tube 9 and uv light tube 10 are respectively arranged on the horizontal rails in the first treatment box 2, the second treatment box 3 and the third treatment box 4.

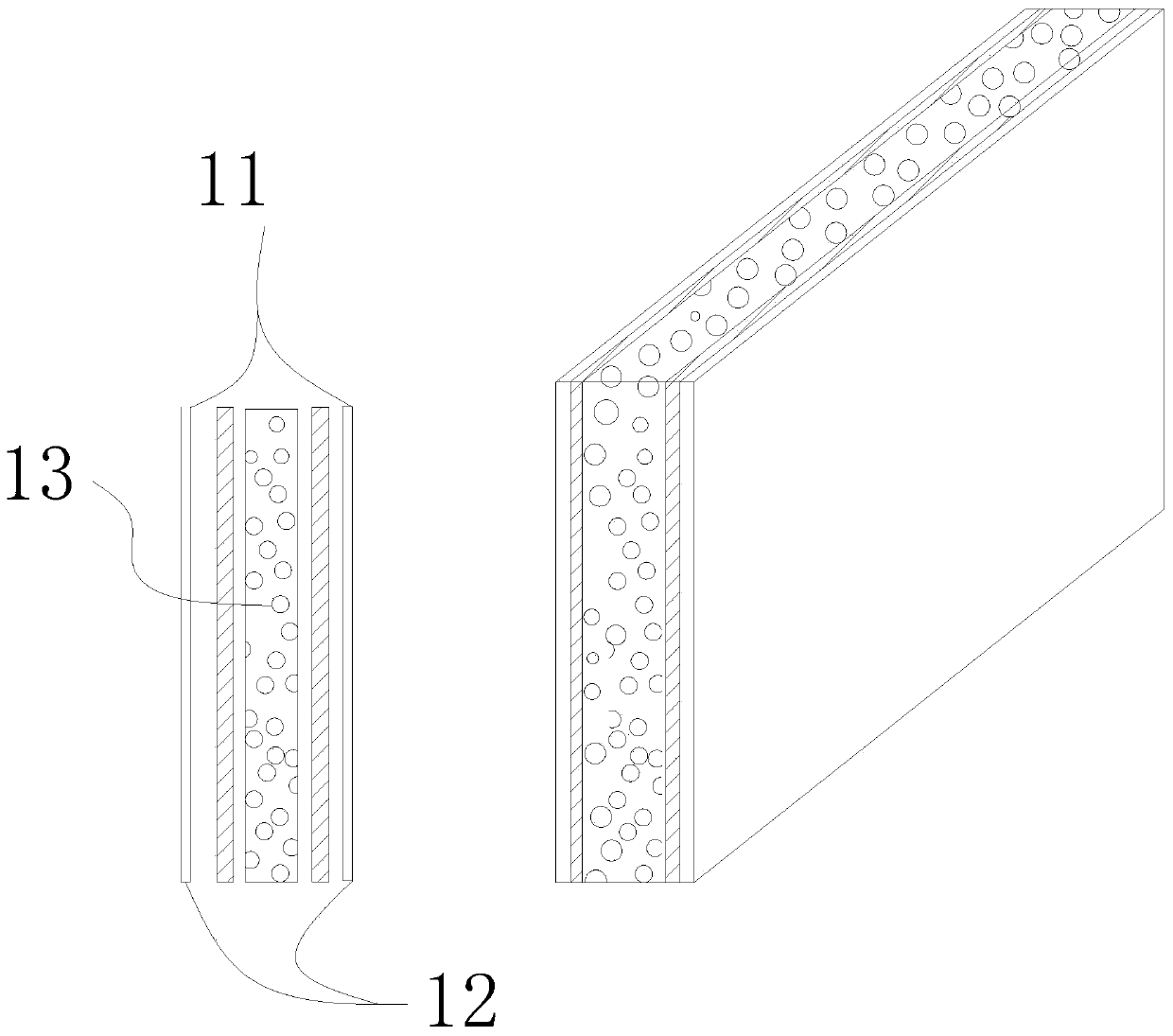

[0033] Wherein the adsorbate filling box 8 has a three-layer structure, which is respectively a filter fabric layer 11, a filter screen 12 and a sponge-filled activated carbon filling layer 13.

[0034] The second processing box 3 and the third processing box 4 are provided with a relay box 14

[0035] The heating lamp tube 9 and the uv light tube 10 are connected to the relay box 14 on the second treatment box 3 and the third treatment box 4 respectively.

[0036] The industrial waste gas is introduced, and the exhaust fan 7 is turned on. Under the directional action of the exhaust fan 7, the exhaust gas enters the first treatment box 2, and the adsorbate filling...

Embodiment 2

[0041] Treatment methods for oil fume and fire smoke exhaust gas

[0042] Open the doors of each treatment box, and set the adsorbate filling box 8, heating lamp tube 9 and adsorbate filling box 8 on the horizontal rails in the first treatment box 2, the second treatment box 3 and the third treatment box 4 respectively.

[0043] The adsorbate filling box 8 has a three-layer structure, which is an organic polymer composite fabric layer 11 with high oil absorption performance, a filter screen 12 and a filling layer 13 added with hydrophobic perlite, ceramsite and coke.

[0044] The second processing box 3 is provided with a relay box 14

[0045] The heating lamp tube 9 is connected to the relay box 14 on the second processing box 3 .

[0046] Feed oily smoke and fire smoke waste gas, turn on the exhaust fan 7, and the exhaust gas enters the first treatment box 2 under the directional action of the exhaust fan 7, and the adsorbate filling box 8 provided in the first treatment bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com