Screw turning machine for segment impermeability test bed

A technology of impermeability test and screw machine, which is applied in the direction of permeability/surface area analysis, measuring devices, manufacturing tools, etc. It can solve the problems of low test efficiency, time-consuming and labor-intensive screwing and loosening of nuts, etc., and achieves exquisite structure and high efficiency. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

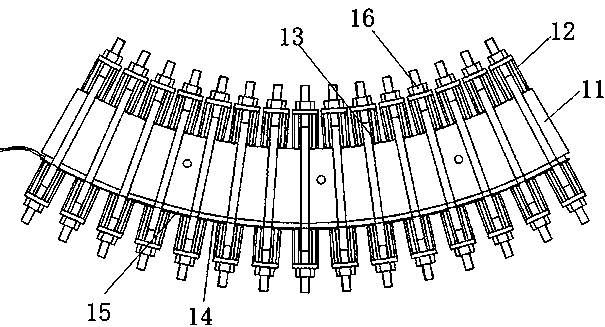

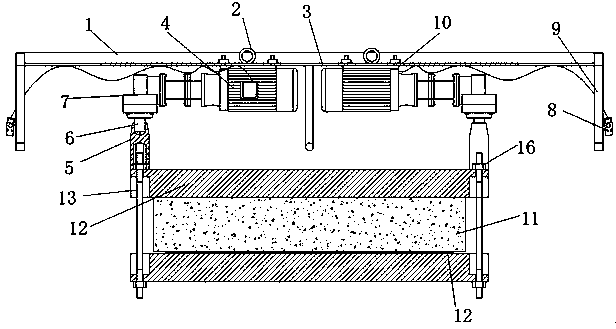

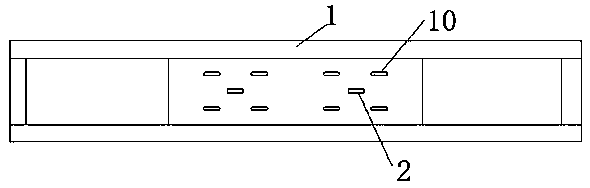

[0020] The specific embodiment of the segment anti-seepage test bench screwing machine involved in the present invention, as Figure 2-3 As shown, the segment anti-seepage test bench screwing machine is used for synchronously screwing the nuts 16 at the two ends of the same fastening cross bar 12 separately. It includes a frame 1. In this embodiment, the frame 1 is a rectangular flat plate structure, which is formed by welding steel plates and steel pipes. This can ensure that the overall structure of the frame 1 is lighter and facilitates processing. The frame 1 is other The specific structure of the basic carrier of the component is not limited in other embodiments, and those skilled in the art can design it arbitrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com