Activated sludge process and biofilm process combined wastewater treatment device

A technology of activated sludge method and biofilm method, which is applied in the field of combined wastewater treatment devices of activated sludge method and biofilm method, can solve the problems of low treatment efficiency, low sludge concentration, poor sludge settling performance, etc., and achieve The effect of low operating cost, less suspended matter in the effluent, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical purpose, technical solution and beneficial effect of the present invention clearer, the technical solution of the present invention will be further described below in conjunction with the drawings and specific embodiments.

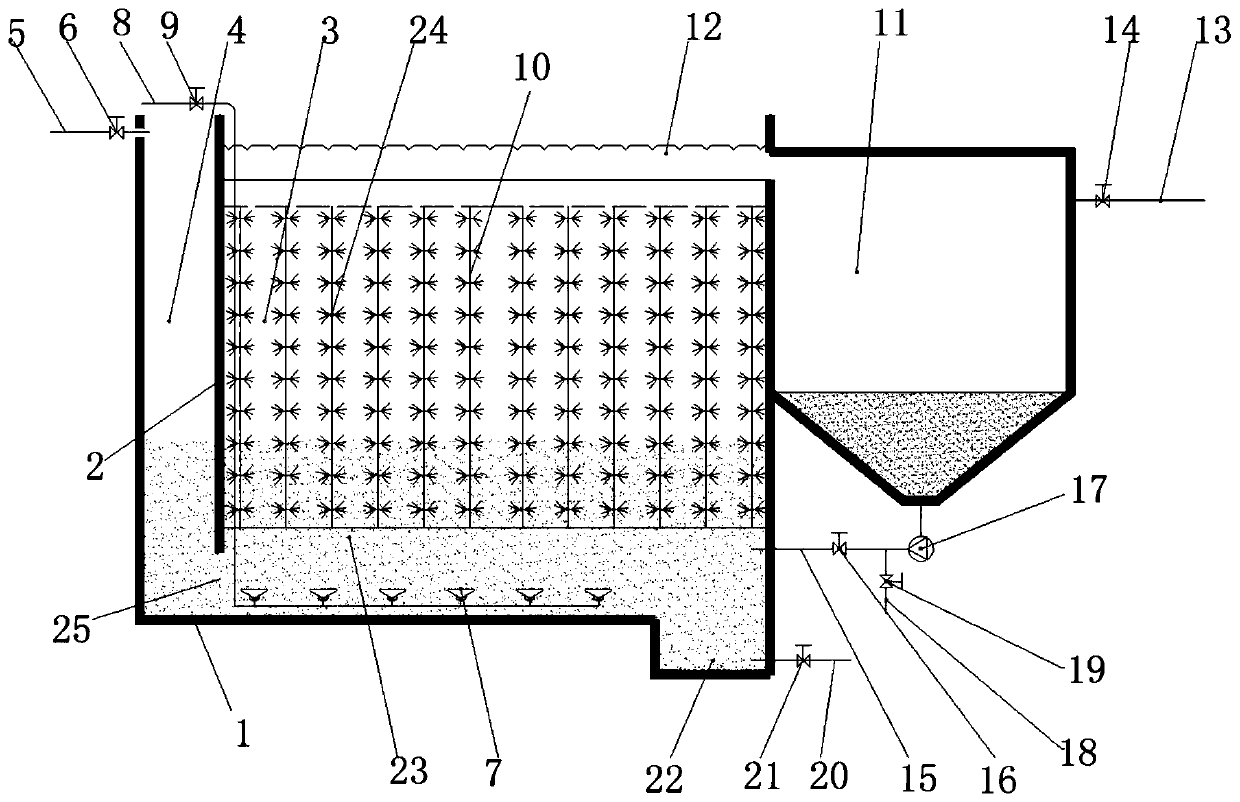

[0022] The specific embodiment of activated sludge method and biofilm method combined wastewater treatment device involved in the present invention, as figure 1 As shown, the treatment device includes a treatment pool 1. In this embodiment, waste water enters the treatment pool 1 for treatment process, and all other structures are arranged on the treatment pool 1. Its structure is a square structure, and it is made of steel or steel concrete. Structure, of course, in other embodiments, the processing tank 1 can also be a circular or polygonal structure, or its specific shape is not limited, and its material is not specifically limited, and those skilled in the art can design arbitrarily according to actual needs.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com