Device and method for pre-coating metal solder on vacuum glass

A technology of metal solder and vacuum glass, which is applied in the field of devices for pre-coating metal solder on vacuum glass, can solve the problems of affecting the vacuum degree of the final product, flux pollution of packaging equipment, and the inability to use solder flux materials, etc., to achieve reduction requirements and thickness Controlled, uniform thickness results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

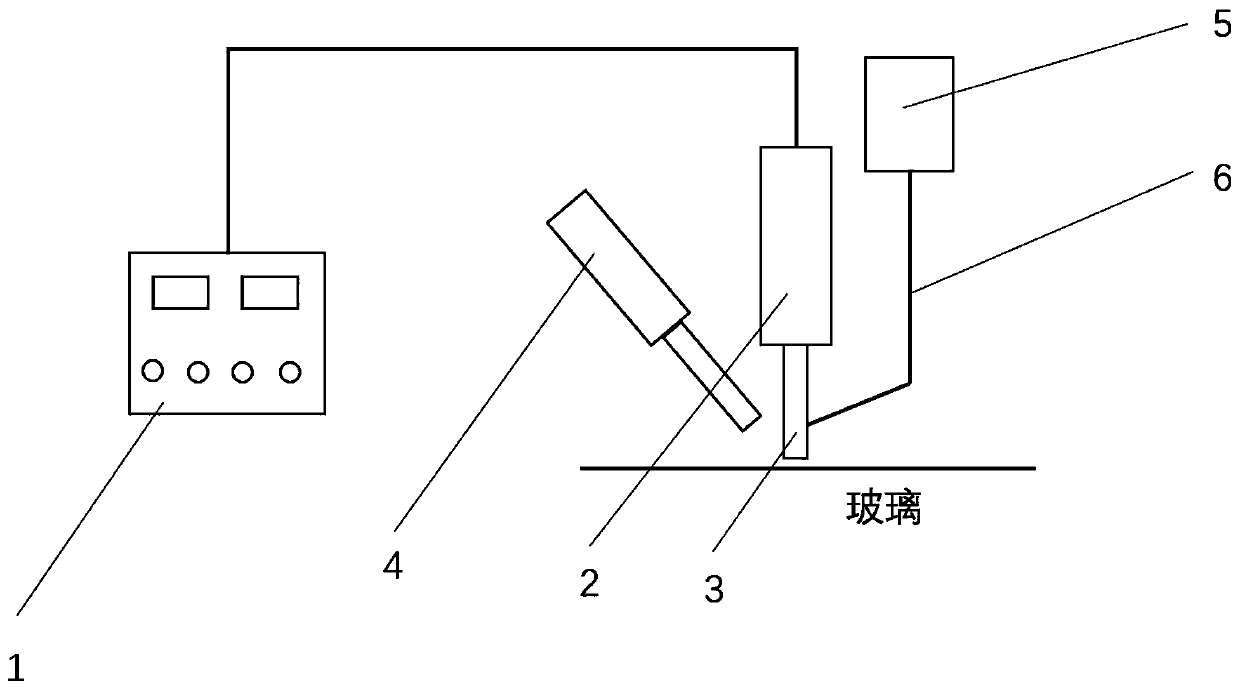

[0027] Such as figure 1 As shown, the device for pre-coating metal solder on vacuum glass includes an ultrasonic electric soldering iron. The ultrasonic electric soldering iron includes an ultrasonic generator 1, an electric soldering iron head 3, a wire feeding device and a heat gun 4, and the transducer 2 of the ultrasonic generator 1 and The electric soldering iron tip 3 is connected to drive the electric soldering iron tip 3 to generate radial vibration; the heat gun 4 is set close to the electric soldering iron tip 3, and the wire feeding device delivers the welding wire to the electric soldering iron tip 3 and before the welding wire touches the electric soldering iron tip 3, the heat gun 4 Preheat the wire.

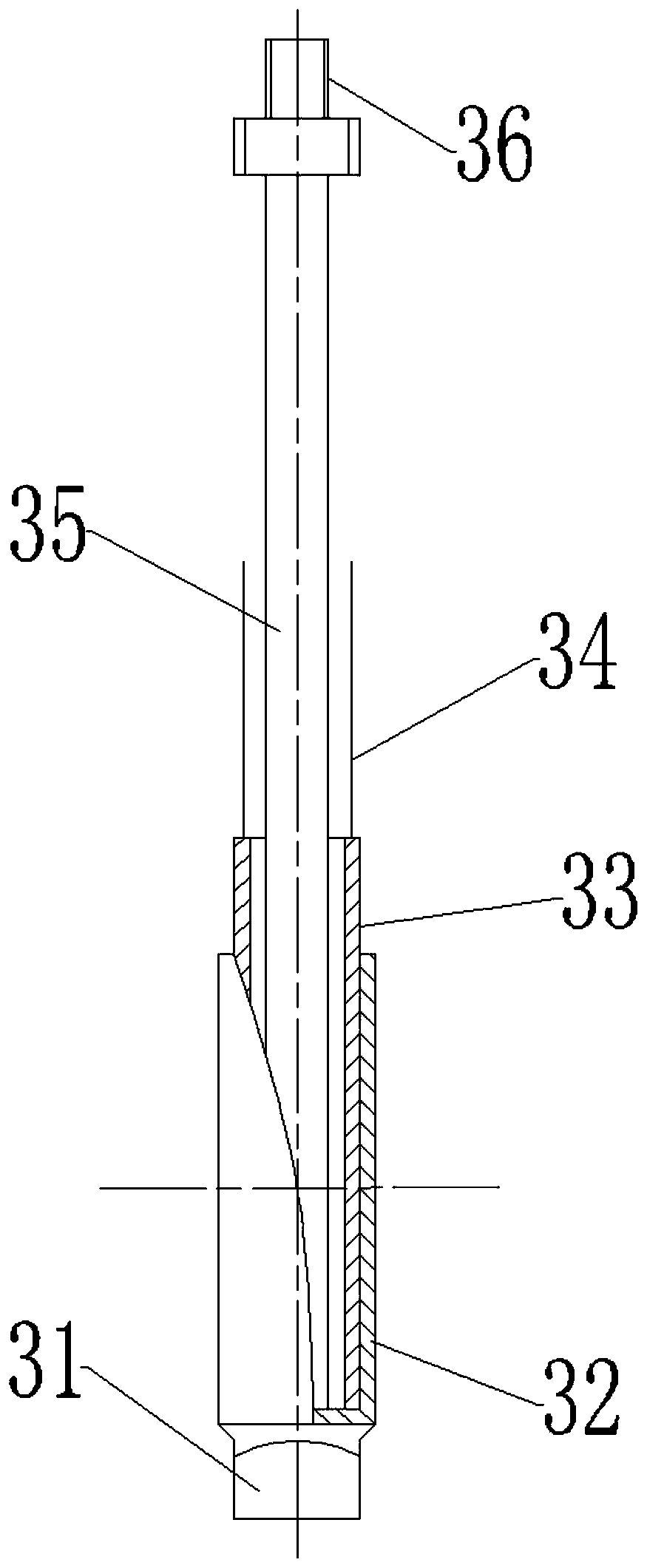

[0028] Such as figure 2 As shown, the electric soldering iron head 3 includes a soldering iron head 31, the rear end of the soldering iron head 31 is provided with an installation cavity, and a ceramic heating element 33 is arranged in the installation cavity, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com