Processing method of aluminate cement added admixture

A technology of aluminate cement and a processing method, which is applied in the processing field of aluminate cement mixed with mixed materials, can solve the problems of high production raw material costs, and achieve the effects of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

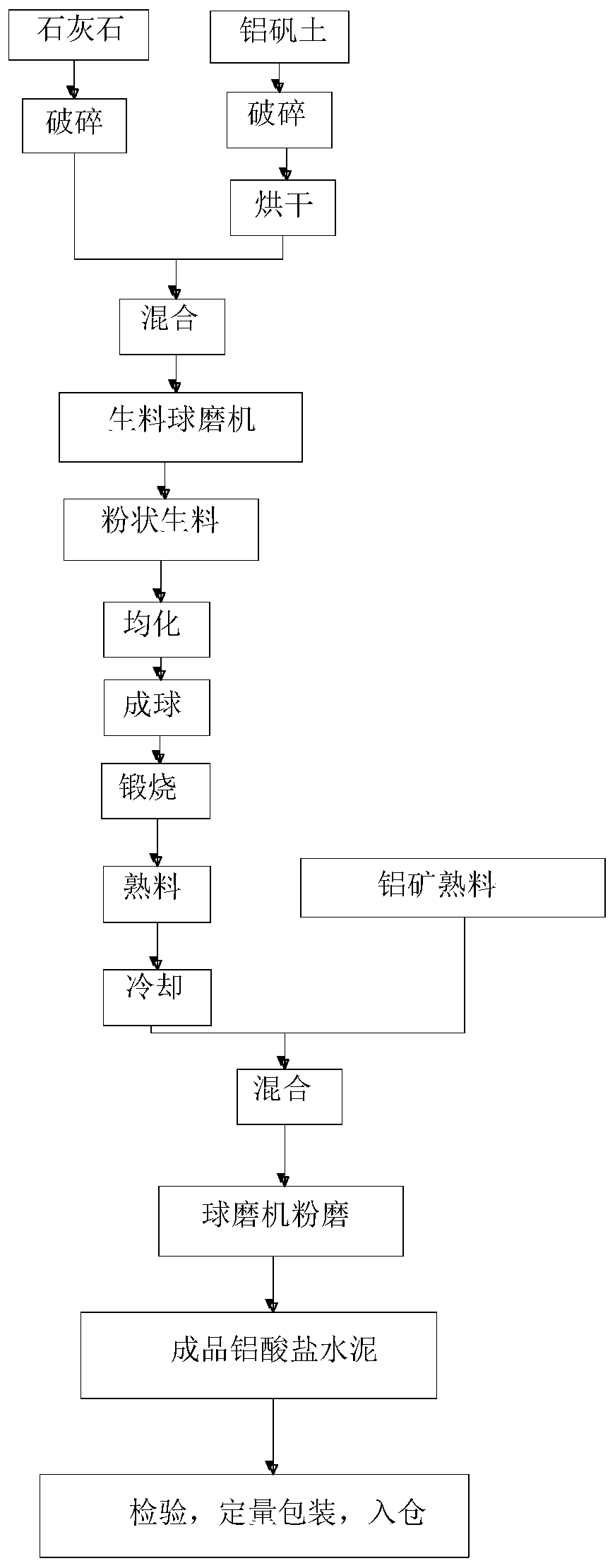

[0024] Such as figure 1 Shown, a kind of processing method of aluminate cement admixture admixture, comprises the following steps:

[0025] Step 1, crushing bauxite and limestone with a crusher respectively, and crushing bauxite material and limestone material with a particle size of no more than 20 mm; before mixing bauxite material with limestone material, the bauxite material is first drying process;

[0026] Step 2, mixing the above-mentioned obtained bauxite material with the limestone material in a ratio of 53%: 47%, to obtain a mixed material;

[0027] Step 3. Grind the above mixed material with a raw meal ball mill, and screen the ground mixed material with a 0.045mm square hole sieve. material;

[0028] Step 4, homogenization;

[0029] Step 5. The homogenized raw meal is pelletized, and then put into a rotary kiln for calcination. The calcination temperature is 1300°C, the calcination time is 240min, and the rotation speed of the rotary kiln is 0.7r / min to obtain ...

Embodiment 2

[0033] Such as figure 1 Shown, a kind of processing method of aluminate cement admixture admixture, comprises the following steps:

[0034] Step 1, crushing bauxite and limestone with a crusher respectively, and crushing bauxite material and limestone material with a particle size of no more than 20 mm; before mixing bauxite material with limestone material, the bauxite material is first drying process;

[0035] Step 2, mixing the above-mentioned gained bauxite material with the limestone material in a ratio of 53%:47%, to obtain a mixed material;

[0036] Step 3. Grind the above mixed material with a raw meal ball mill, and screen the ground mixed material with a 0.045mm square hole sieve. material;

[0037] Step 4, homogenization;

[0038] Step 5. The homogenized raw meal is pelletized, and then put into a rotary kiln for calcination. The calcination temperature is 1350°C, the calcination time is 230min, and the rotation speed of the rotary kiln is 0.7r / min to obtain cl...

Embodiment 3

[0042] Such as figure 1 Shown, a kind of processing method of aluminate cement admixture admixture, comprises the following steps:

[0043] Step 1, crushing bauxite and limestone with a crusher respectively, and crushing bauxite material and limestone material with a particle size of no more than 20 mm; before mixing bauxite material with limestone material, the bauxite material is first drying process;

[0044] Step 2, mixing the above-mentioned obtained bauxite material with the limestone material in a ratio of 53%: 47%, to obtain a mixed material;

[0045] Step 3. Grind the above mixed material with a raw meal ball mill, and screen the ground mixed material with a 0.045mm square hole sieve. material;

[0046] Step 4, homogenization;

[0047] Step 5. The homogenized raw meal is pelletized, and then put into a rotary kiln for calcination. The calcination temperature is 1400°C, the calcination time is 210min, and the rotation speed of the rotary kiln is 0.7r / min to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com