Protective lubricant and preparation method thereof

A lubricant and antioxidant technology, applied in the field of protective lubricants and its preparation, can solve the problems of poor anti-friction and anti-sticking effects, low oil film strength, discoloration of aluminum plates, etc., and achieve good retention, high oil film strength, and excellent adsorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In an embodiment of the present invention, the method for preparing the protective lubricant described above is characterized in that the method includes:

[0030] Weigh each component according to the above-mentioned protective lubricant formula for use;

[0031] Put the fatty alcohol polyoxyethylene polyoxypropane, sodium polyacrylate and reverse block polyether into a container, heat to 60-80°C, stir and mix uniformly to obtain a first mixture;

[0032] The N-methylmorpholine, hydrogenated grease, antioxidant and base oil are added to the first mixture, heated to 100-120° C., stirred and mixed uniformly, to obtain.

[0033] In a preferred embodiment of the present invention, the above-mentioned fatty alcohol polyoxyethylene polyoxypropane, sodium polyacrylate and reverse block polyether are put into a container, heated to 60-80°C, stirred and mixed uniformly, The steps of obtaining the first mixture specifically include:

[0034] Put the fatty alcohol polyoxyethylene polyoxyp...

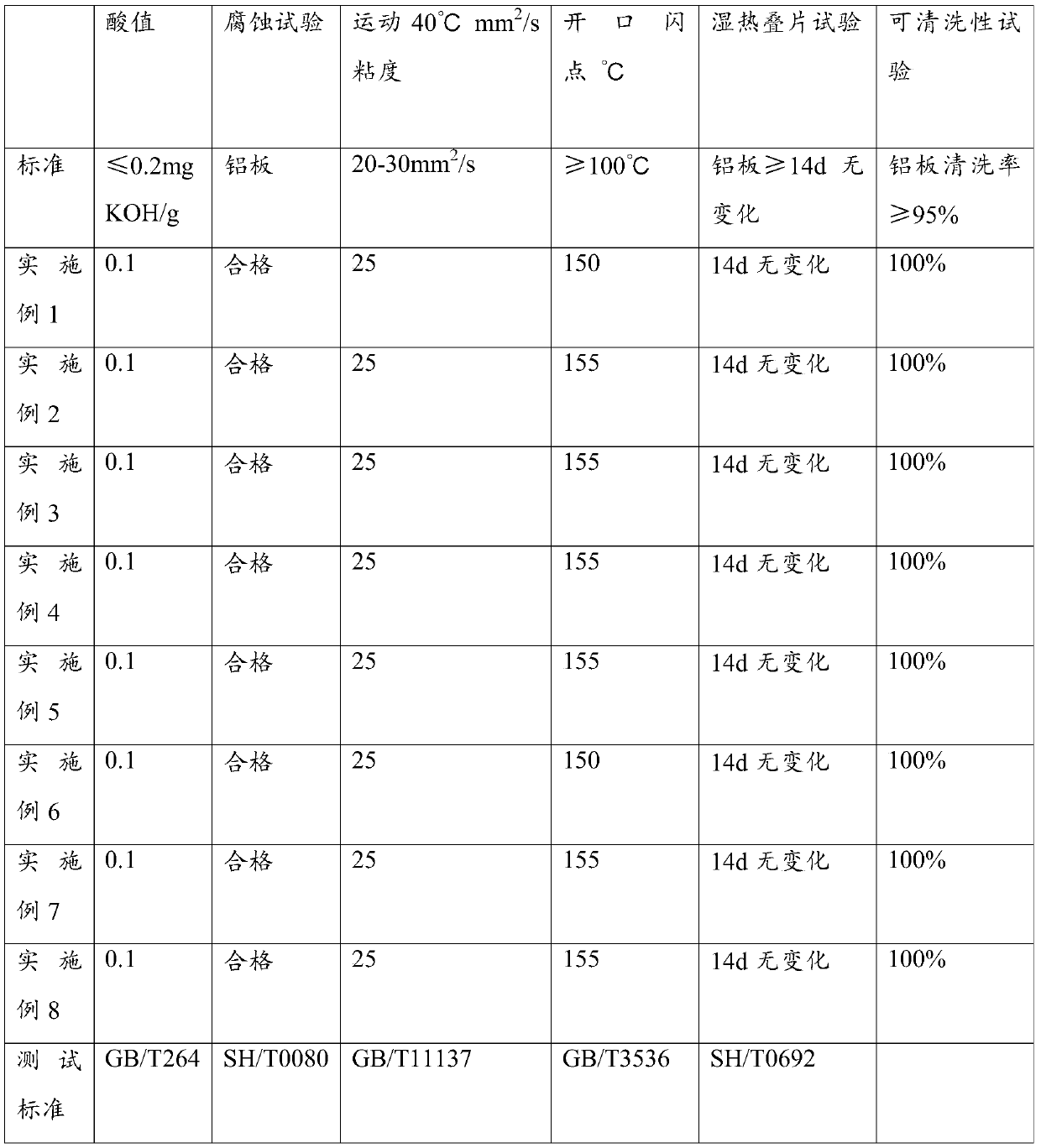

Embodiment 1

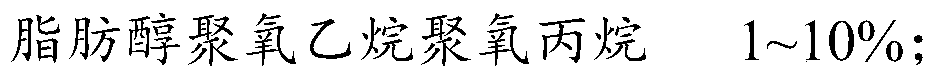

[0039] A protective lubricant, including the following raw materials in weight percentage:

[0040] Fatty alcohol polyoxyethane polyoxypropane 1.5%, N-methylmorpholine 0.2%, sodium polyacrylate 1%, reverse block polyether 1%, hydrogenated grease 5%, antioxidant T501 0.1%, balance The amount is the base oil.

[0041] Weigh each component according to the above-mentioned protective lubricant formula for use;

[0042] Put the fatty alcohol polyoxyethylene polyoxypropane, sodium polyacrylate and reverse block polyether into a container, heat to 60°C, stir and mix uniformly to obtain a first mixture;

[0043] The N-methylmorpholine, hydrogenated grease, antioxidant and base oil are added to the first mixture, heated to 100° C., stirred and mixed uniformly, to obtain.

Embodiment 2

[0045] A protective lubricant, including the following raw materials in weight percentage:

[0046] Fatty alcohol polyoxyethane polyoxypropane 1%, N-methylmorpholine 0.3%, sodium polyacrylate 1.5%, reverse block polyether 2%, hydrogenated grease 6%, antioxidant BHT 0.2%, balance The amount is the base oil.

[0047] Weigh each component according to the above-mentioned protective lubricant formula for use;

[0048] Put the fatty alcohol polyoxyethylene polyoxypropane, sodium polyacrylate and reverse block polyether into a container, heat to 80°C, stir and mix uniformly to obtain a first mixture;

[0049] The N-methylmorpholine, hydrogenated fat, antioxidant and base oil are added to the first mixture, heated to 120° C., stirred and mixed evenly to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com