One-steel dual-purpose cold-rolled high-strength steel based on carbon partitioning process and manufacturing method thereof

A technology of carbon distribution and high-strength steel, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of inability to cover strength levels and steel types, extremely high production line capacity requirements, and difficult process control, etc., to achieve product integration Good performance, reduce the production and operation cost of the enterprise, and avoid the effect of reheating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Production of TRIP780 steel grades:

[0024] The smelting chemical composition includes: 0.20% C, 1.6% Si, 1.9% Mn, 0.20% Cr, 0.040% Nb, 0.035% Ti, 0.035% Al, 0.0021% B, 0.007% S, 0.003% P in terms of weight percentage.

[0025] Hot rolling process:

[0026] The heating temperature is 1230°C, and the heat preservation time is 2.2 hours; the starting rolling temperature is 1150°C; the intermediate billet temperature after rough rolling is 990°C; the final rolling temperature is 890°C; the coiling temperature is 710°C, and finally a 3.2mm thick hot rolled steel plate .

[0027] Cold rolling process:

[0028] The reduction rate of cold rolling is 62.5%, the rolling target specification is 1.2mm, the temperature of the acid solution is 86°C, and the pickling speed is 110m / min.

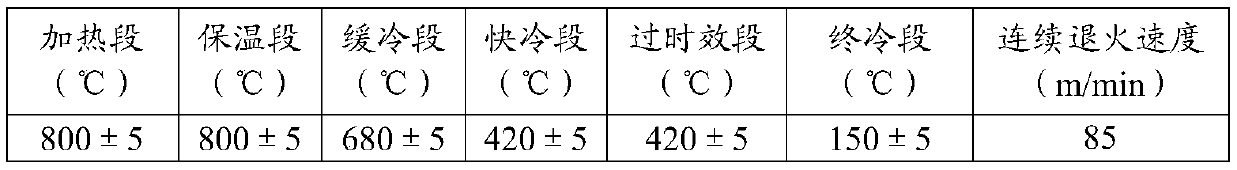

[0029] The annealing process for TRIP780 production by rapid cooling to the bainite medium temperature transformation zone is:

[0030]

[0031] Through heat preservation in the two-phase zon...

Embodiment 2

[0035] QP980 steel production:

[0036] The smelting chemical composition includes: 0.22% C, 1.8% Si, 2.2% Mn, 0.25% Cr, 0.035% Nb, 0.04% Ti, 0.03% Al, 0.0025% B, 0.009% S, 0.007% P in terms of weight percentage.

[0037]Hot rolling process: heat the billet in a walking heating furnace at a heating temperature of 1250°C and hold for 2.3 hours; the starting rolling temperature is 1160°C; the intermediate billet temperature after rough rolling is 980°C; the final rolling temperature is 885°C; The coiling temperature is 700° C., and a hot-rolled steel sheet with a thickness of 2.5 mm is finally obtained.

[0038] Cold rolling process:

[0039] The reduction rate of cold rolling is 60%, the rolling target specification is 1.0mm, the temperature of the acid solution is 88°C, and the pickling speed is 100m / min.

[0040] The annealing process for QP980 production by rapid cooling to the martensitic low-temperature transformation zone is:

[0041]

[0042] Through heat preservat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com