Vibration and noise reduction shockproof telescopic device and method

A technology of vibration reduction, noise reduction and telescopic device, applied in the fields of civil engineering and earthquake resistance, can solve the problems of lack of displacement restraint device, noise pollution, traffic paralysis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

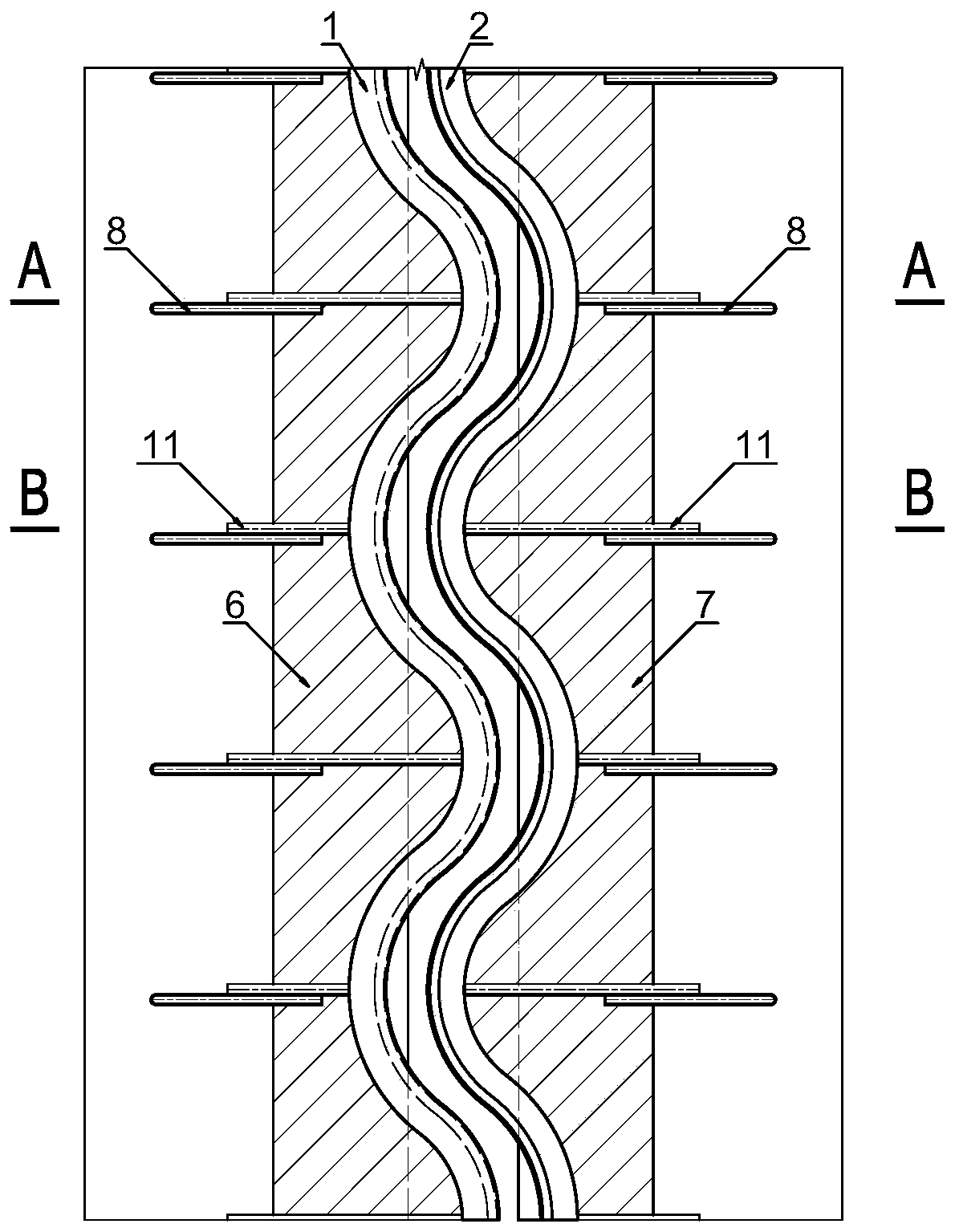

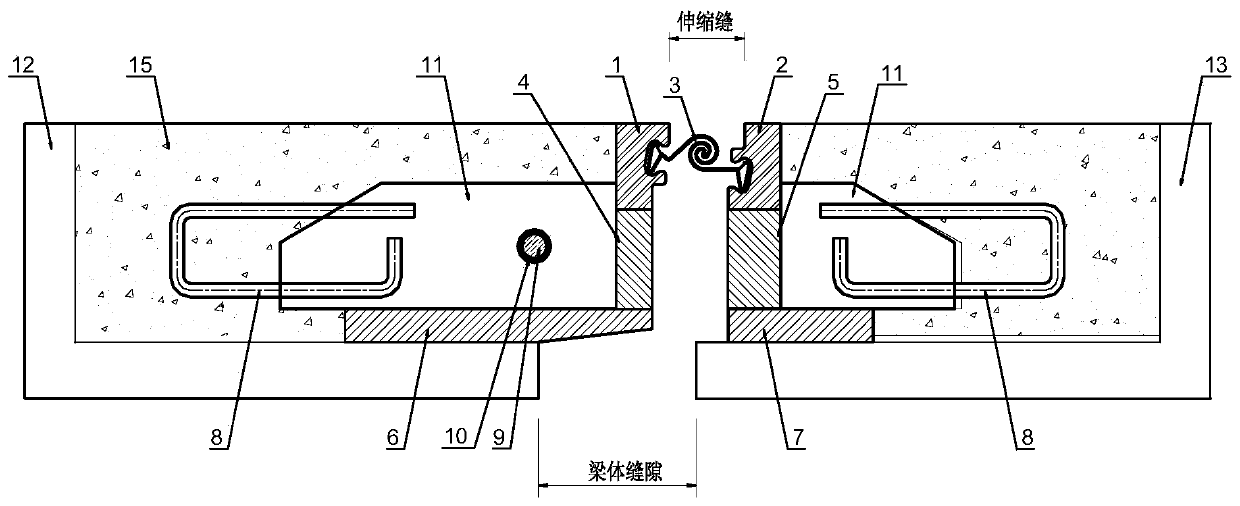

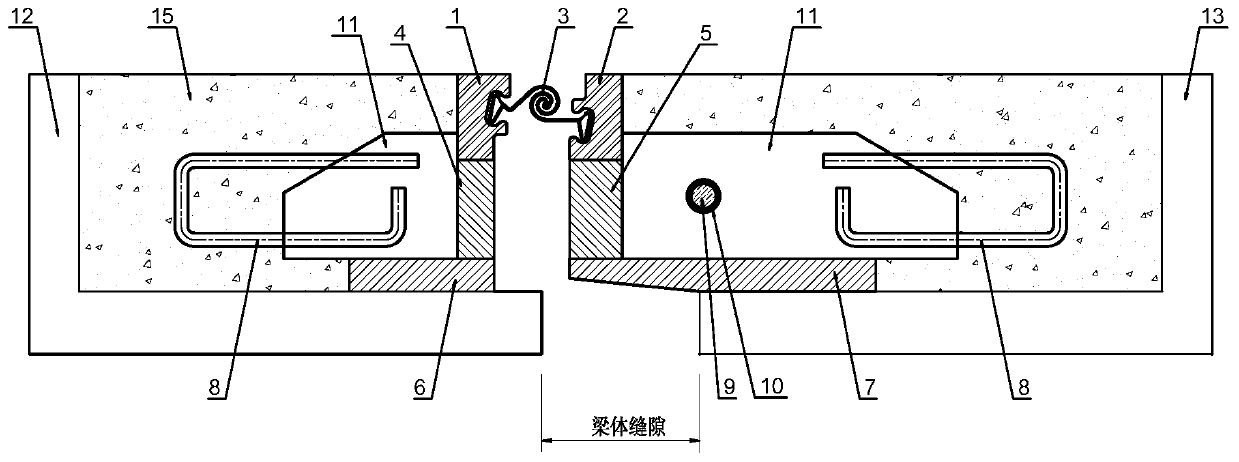

[0051] please see Figure 1 to Figure 8 :

[0052] A shock-absorbing and noise-reducing anti-shock telescopic device, characterized in that it includes Shaped steel edge beam , Limiter ;

[0053] The special-shaped steel edge beam comprises a first special-shaped steel edge beam (1) and a second special-shaped steel edge beam (2); the first special-shaped steel edge beam (1) and the second special-shaped steel edge beam (2) are both It is wave-shaped and arranged in parallel along the edge of the seam, which weakens the sudden change of the edge of the expansion joint. This arrangement improves the deformation ability of a single seam and can effectively reduce the driving noise at the same time. In terms of section shape design of section steel, the shape and position relationship of the second special-shaped steel side beam (2) is formed by rotating the first special-shaped steel side beam (1) by 180°, and the two sides of the expansion joint formed by interlocking arran...

Embodiment 2

[0065] A method for realizing vibration reduction, noise reduction and earthquake prevention of bridge expansion joints, characterized in that,

[0066] Step 1, in structural design:

[0067] expansion joint Special-shaped steel edge beams in cross-sectional shape design , the shape and position relationship of the second special-shaped steel edge beam (2) is formed by the rotation of the first special-shaped steel edge beam (1) by 180°. Type, an S-shaped cavity is formed inside, so that the cross-sectional shape of the special-shaped steel on both sides of the expansion joint is complementary and interlocking, which changes the noise generation environment of the expansion joint cavity, is conducive to noise reduction, and improves the expansion joint. deformation adaptability and anti-collision ability.

[0068] in the bridge plane , the special-shaped steel side beams of the expansion joints are arranged in waves, which weakens the abruptness of the edges of the expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com