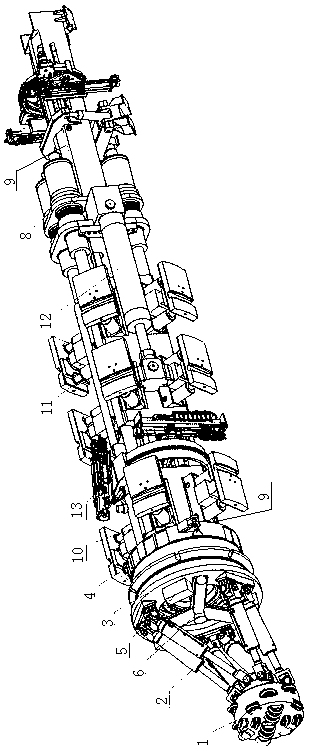

Novel soft arm TBM and tunnel boring method thereof

A flexible arm, a new type of technology, applied in the new flexible arm TBM and its excavation field, can solve the problems of low excavation efficiency of the flexible arm roadheader, and achieve the effect of meeting the needs of on-site construction, improving the excavation efficiency and improving the applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

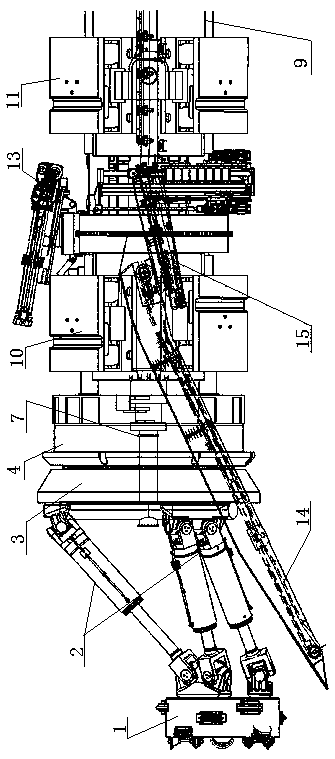

[0047] Embodiment 4: a kind of excavation method of novel flexible arm TBM, such as Figure 9 As shown, the specific steps are as follows:

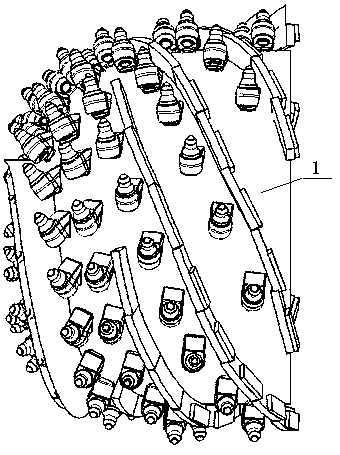

[0048] S1: The parallel cylinder arm 2 is fully retracted, the central axis of the rotary cutting cutterhead 1 of the cutterhead tunneling system coincides with the central axis of the main bearing 4 of the slewing mechanism, and the cutterhead tunneling system is in the initial state;

[0049] S2: The background controller determines the pre-excavation contour according to the tunnel boundary parameters, and plans the movement route of the rotary cutter head 1;

[0050] S3: The background controller sets the displacement of the six parallel oil cylinders of the parallel oil cylinder arm 2 according to the movement route of the rotary cutter head 1 planned in S2;

[0051] S4: When the TBM starts to excavate, the auxiliary support shoe 10 and the main support shoe 11 are braced tightly on the cave wall, the background controller controls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com