Engine

An engine, sliding connection technology, applied in the direction of machine/engine, mechanical equipment, etc., can solve problems such as height difference, and achieve the effect of reducing volume, sufficient air intake, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

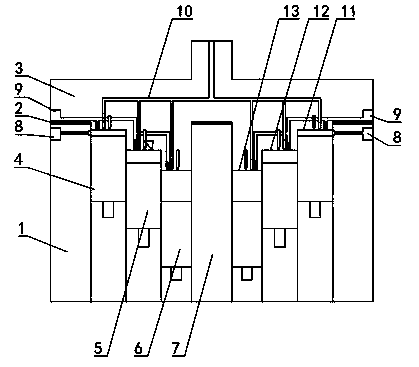

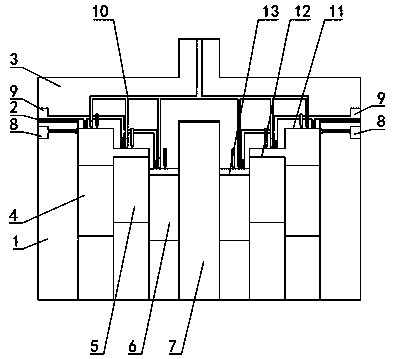

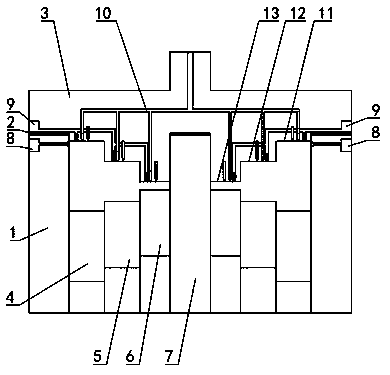

[0032] Such as figure 1 As shown: the upper side of the cylinder block 1 is closed by the cylinder head 3, the cylinder block 1 and the cylinder head 3 are detachably connected, a cylinder gasket 2 is arranged between the cylinder block 1 and the cylinder head 3, and the cylinder gasket 2 connects the cylinder body 1 and the cylinder head 3. The cylinder heads 3 are sealed.

[0033] The piston is slidably installed in the cylinder block 1, and the lower side of the cylinder block 1 is provided with a crankcase. The crankshaft rotates and is installed in the crankcase, and the crankshaft is arranged horizontally. Each piston is connected to the crankshaft through a connecting rod, the upper end of each connecting rod is rotationally connected to the corresponding piston, and the lower end of the connecting rod is rotationally connected to the crankshaft, thereby converting the reciprocating motion of the piston into the rotational motion of the crankshaft.

[0034] The upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com