Extrusion forming machine for pastry food processing

A food processing and molding machine technology, applied in the field of food processing, can solve the problems of inconvenient mold replacement, low processing efficiency, and low production efficiency, and achieve the effects of saving processing consumables, fast molding speed, and simple and convenient extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

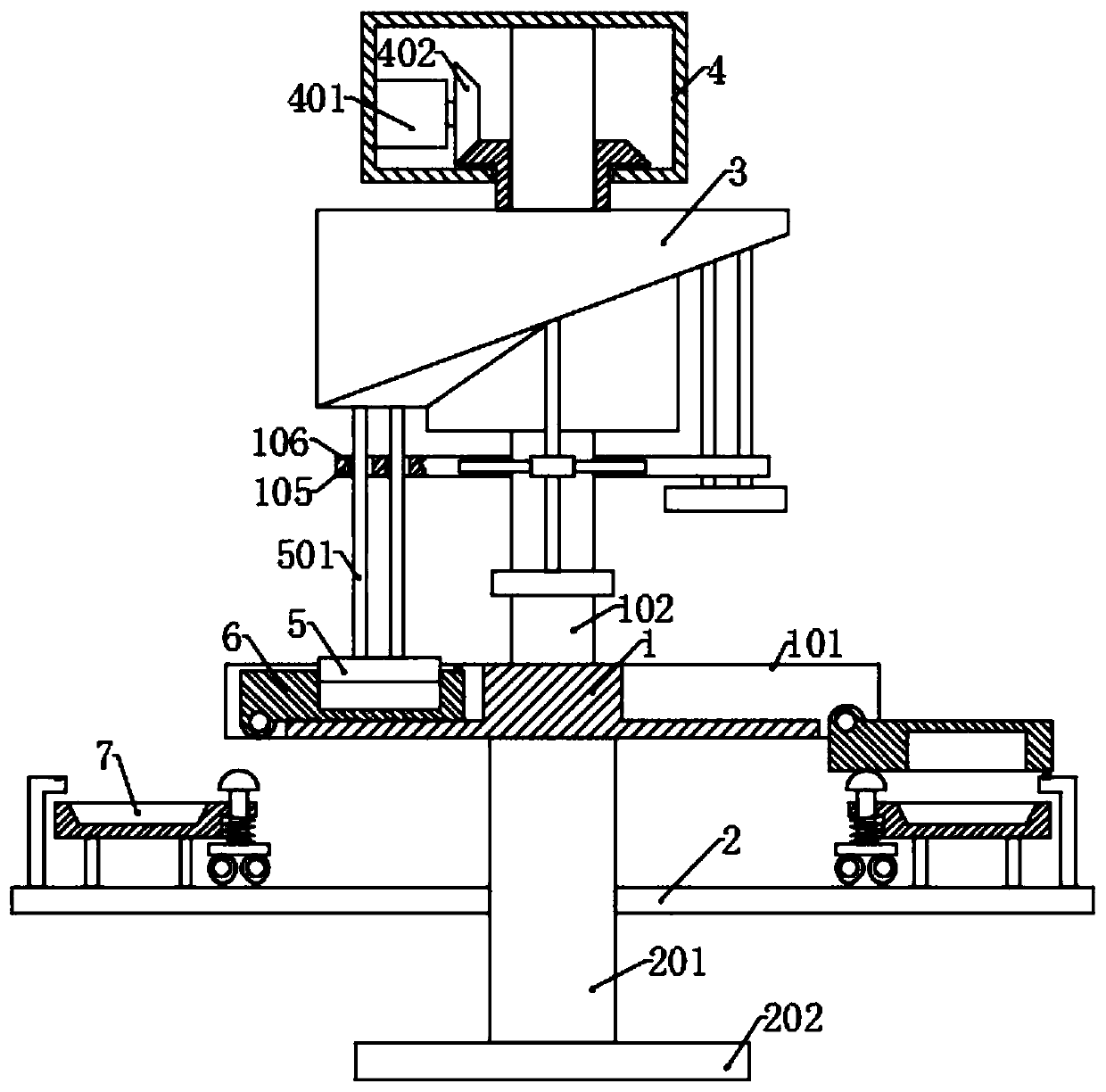

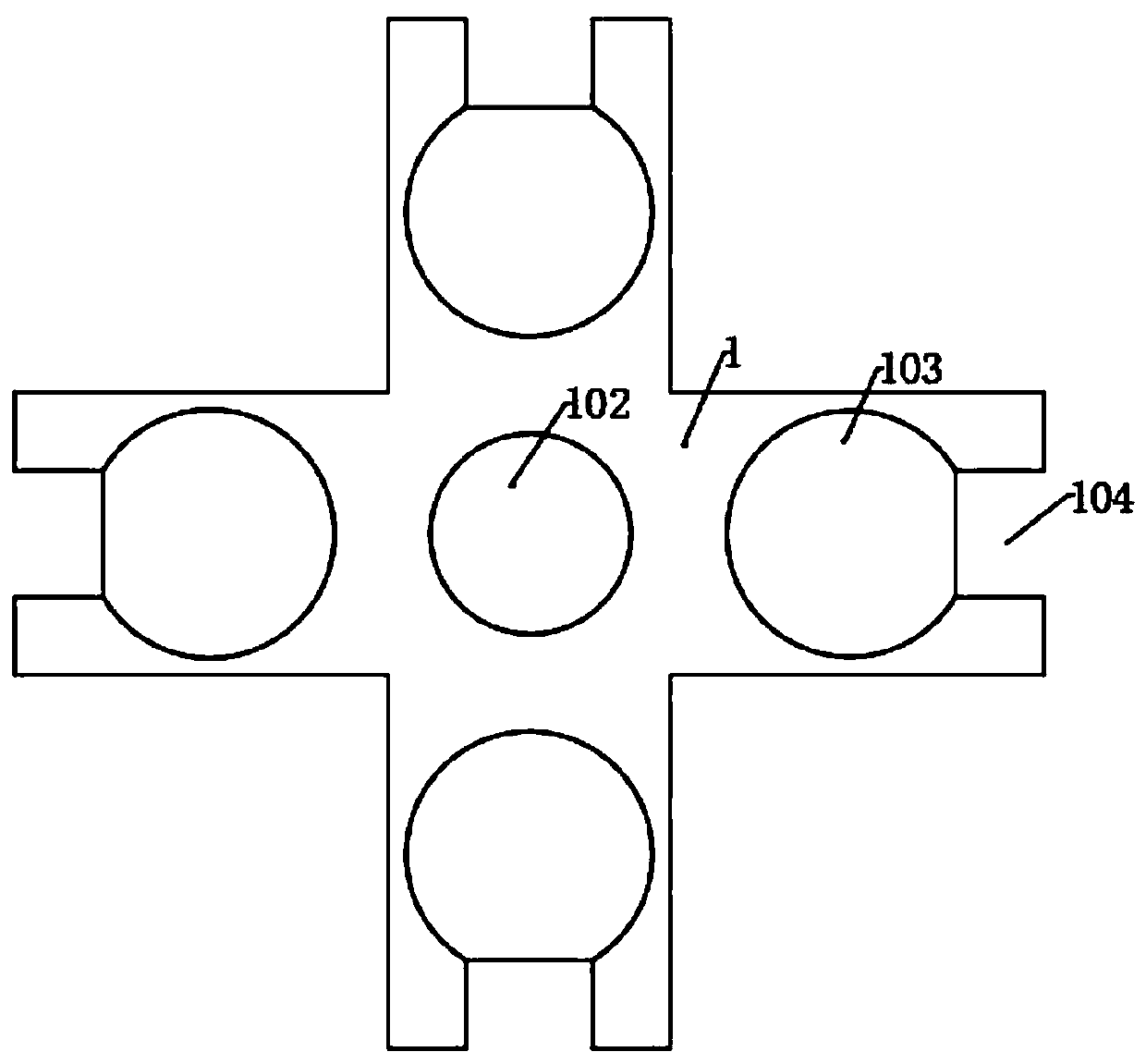

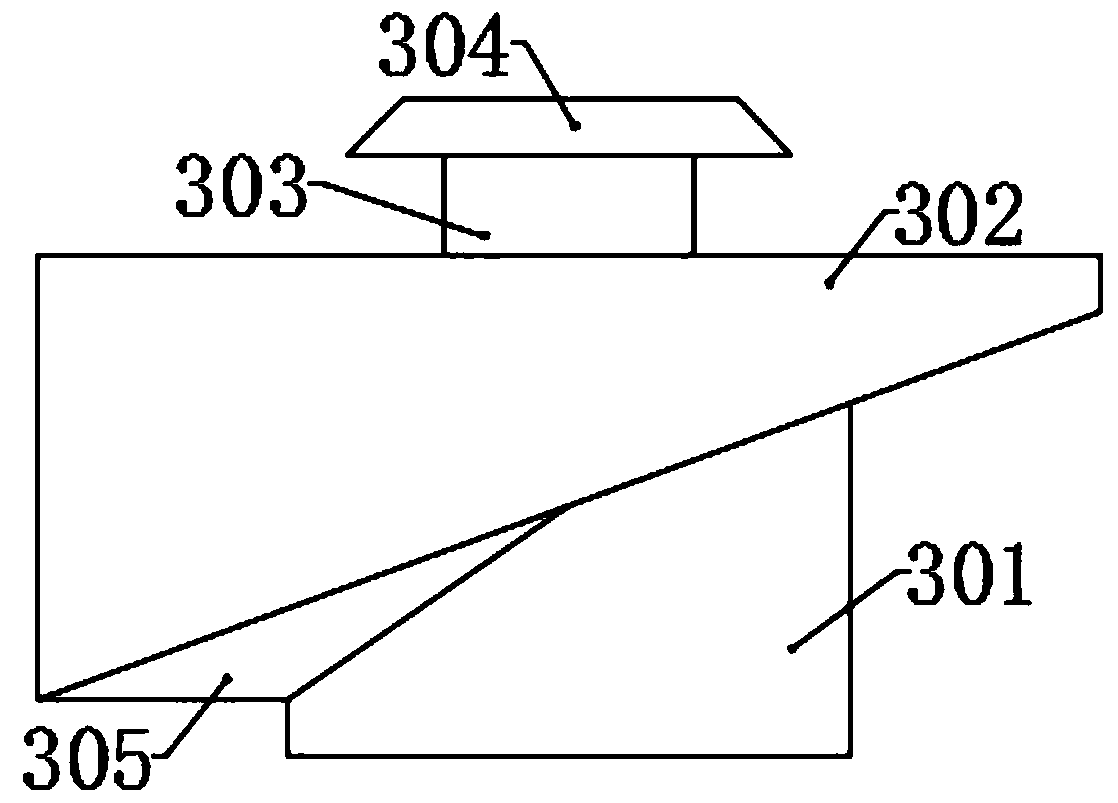

[0034] Please refer to the accompanying drawings, the present invention provides a technical solution: an extrusion molding machine for pastry food processing, including a fixed table 1, a plurality of turning grooves 101 are evenly arranged on the fixed table 1 along the circumferential direction, and the fixed table 1 1 is fixed with an upper support column 102 in the middle of the top surface, and a lower support column 201 is fixed in the middle of the bottom surface. The upper part of the upper support column 102 is provided with a drive assembly 3, and the top is fixed with a motor box 4. Forming assembly 6, corresponding to forming assembly 6 on the said driving assembly 3 is provided with a plurality of extruding assemblies along the circumferential direction, the middle part of the lower supporting column 201 is provided with a plurality of fixing plates 2 evenly along the circumferential direction, and the bottom end is fixed with a base 202 , the blanking assembly 7 ...

Embodiment 2

[0043] On the basis of Embodiment 1, an annular shaft 609 is fixed on the bottom plate of the supporting groove 103, and an arc groove 608 is provided on the turning plate 601, and the annular shaft 609 is sleeved in the arc groove 608, And the center of circle of the ring shaft 609 coincides with the axis line of the connecting shaft 602, the first spring 610 is sleeved on the ring shaft 609, one end of the first spring 610 is in contact with the side of the turning plate 601, and the other end is in contact with the fixed platform 1 bottom surface contact.

[0044] The working principle of this embodiment is basically the same as that of Embodiment 1, the difference is that when the turning plate 601 is turned over 180°, the arc groove 608 moves along the annular shaft 609, and by compressing the first spring 610, the turning plate The rotation of 601 provides a buffering effect, avoiding problems such as damage to the contact switch 705 due to excessive force exerted by the...

Embodiment 3

[0046] On the basis of the second embodiment, a moving assembly 8 is provided below the material receiving plate 701, and the moving assembly 8 includes a moving plate 801, an electromagnet 802 is fixed on the bottom surface of the moving plate 801, and a moving rod 803 is fixed at the center , the bottom surface of the material receiving tank is provided with a plate groove, the fixed plate 2 is located in the plate groove, the corresponding fixed limit plate 805 is fixed on the fixed plate 2, and the top surface of the limit plate 805 is provided with a permanent magnet 807 A third spring 806 is provided below the limiting plate 805, and the bottom end of the moving rod 803 passes through the spring plate 804 and the third spring 806 and is fixed to the spring plate 804.

[0047] When the molded pastry fell on the glutinous rice paper of the feeding tank, the electromagnet 802 was energized, so that the electromagnet 802 and the permanent magnet 807 were mutually repelled, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com