Packing medium of extruded tube piece and manufacturing process of extruded tube piece

A technology for filling medium and manufacturing process, which is applied in the field of filling medium for extruded pipe fittings, can solve the problems of high equipment cost, high technical difficulty, slow development, etc., and achieves simple and convenient extrusion, reduced production cost, and easy industrialized production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

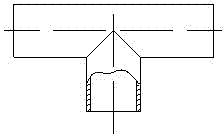

[0020] Such as figure 1 As shown, it is a T-shaped tee with an outer diameter of Φ12. First, the filling medium for the extruded pipe fitting is prepared, and the industrial salt NaCl 30% is 600g and the ammonium bicarbonate NH4HCO3 70% is 1400g and mixed evenly.

[0021] The manufacturing process steps of extruded pipe fittings are as follows:

[0022] 1. Cutting the pipe fittings, intercepting 50 copper pipes with an outer diameter of Φ12 and a length of 80mm;

[0023] 2. Use a powder filling machine to fill the pipe-through parts after blanking in step 1 with medium, and measure the filling density so that the extrusion length requirement is met. The measured density is 0.5g / ;

[0024] 3. Extrude the pipe fitting after filling the medium in step 2 with a hydraulic press, and there is no time interval between the completion of the filling medium process in the described step 2 and the beginning of the extrusion process in the step 3;

[0025] 4. Place the extruded pipe fit...

Embodiment 2

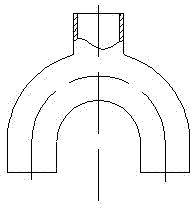

[0029] Such as figure 2 As shown, it is a Y-shaped tee with an outer diameter of Φ9.0. First, prepare the filling medium for the extruded pipe fittings, and mix them uniformly according to industrial salt NaCl 99% in total 2970g and ammonium bicarbonate NH4HCO3 1% in total 30g.

[0030] The manufacturing process steps of extruded pipe fittings are as follows:

[0031] 1. Cutting the pipe fittings, intercepting 100 iron pipes with an outer diameter of Φ9.0 and a length of 80mm;

[0032] 2. Use a powder filling machine to fill the pipe-through parts after blanking in step 1 with medium, and measure the filling density so that the extrusion length requirement is met. The measured density is 2.0g / ;

[0033] 3. Extrude the pipe fitting after filling the medium in step 2 with a hydraulic press, and the interval between the completion of the filling medium process in the described step 2 and the start of the extrusion process in the step 3 is 12 hours;

[0034] 4. Temper the extru...

Embodiment 3

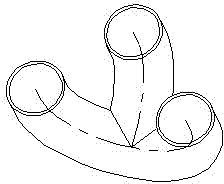

[0041] Such as image 3As shown, it is a three-jaw type tee with an outer diameter of Φ9.5. First, prepare the filling medium for the extruded pipe fitting, and mix evenly according to 1625g of industrial salt NaCl 65% and 875g of ammonium bicarbonate NH4HCO3 35%.

[0042] The manufacturing process steps of extruded pipe fittings are as follows:

[0043] 1. Cutting the pipe fittings, intercepting 50 aluminum pipes with an outer diameter of Φ9.5 and a length of 100mm;

[0044] 2. Use a powder filling machine to fill the pipe-through parts after blanking in step 1 with medium, and measure the filling density so that the extrusion length requirement is met. The measured density is 3.5g / ;

[0045] 3. Squeeze the pipe fitting after filling the medium in step 2 with a hydraulic press, and the interval between the completion of the filling medium process in the described step 2 and the start of the extrusion process in the step 3 is 72 hours;

[0046] 4. Temper the extruded pipe fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com