Design method of a general-purpose industrial reverse osmosis membrane element product

A reverse osmosis membrane and design method technology, which is applied in reverse osmosis, semipermeable membrane separation, chemical instruments and methods, etc., can solve the problems of increasing the design and development cost of industrial membrane elements, increasing the difficulty of membrane element product design, and scrapping membrane products. , to achieve the effect of realizing industrialized operations, avoiding insufficient cutting size, and reducing design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

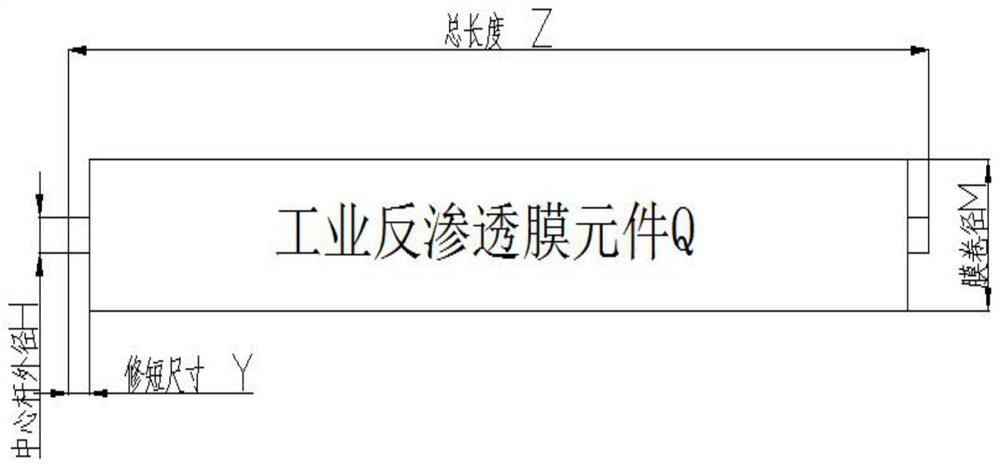

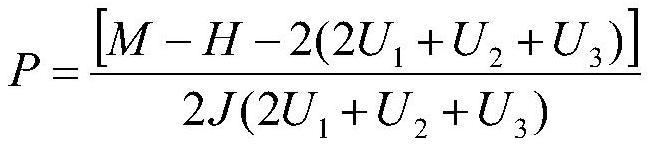

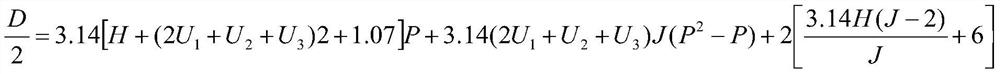

[0034] Example 1: In this example, the BW-8040 membrane element is designed as an example. Firstly, it is determined that the roll diameter of the designed membrane element is M=190mm, the shortening dimension Y=20mm, the total length of the membrane element Z=1016mm, and the number of pages J= On page 22, the outer diameter of the central rod H=38mm; then calculate the cutting width A of the diaphragm, the cutting width B of the water inlet screen, and the cutting width C of the water-producing guide cloth according to the formula (1); determine the selection according to the process requirements The diaphragm thickness U 1 =0.13mm, the thickness of the water inlet screen U 2 =0.8636mm, the thickness of water-producing guide cloth U 3 = 0.254mm, according to the formula (2), calculate the number of turns of the diaphragm in the winding process P = 2.46 circles; then calculate the cutting length of the diaphragm according to the formula (3) and formula (4) D = 1788mm, advance...

Embodiment 2

[0035] Embodiment 2: This embodiment takes the RW-4040 membrane element as an example to design, first determine the roll diameter of the designed membrane element M = 90mm, the shortening dimension Y = 30mm, the total length of the membrane element Z = 1016mm, the number of pages J = Page 6, the outer diameter of the central rod H=20mm; then calculate the cutting width A of the diaphragm, the cutting width B of the water inlet screen, and the cutting width C of the water-producing guide cloth according to the formula (1); determine the selection according to the process requirements The diaphragm thickness U 1 =0.13mm, the thickness of the water inlet screen U 2 =0.762mm, the thickness of water-producing guide cloth U 3 = 0.254mm, according to the formula (2), calculate the number of turns of the diaphragm during the winding process P = 4.4 circles; then calculate the cutting length of the diaphragm according to the formula (3) and formula (4) D = 1564mm, The cutting length...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com