A treatment equipment for nickel or phosphorus waste liquid

A technology for treating equipment and waste liquid, which is applied in metallurgical wastewater treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve environmental protection hazards and become more and more prominent, and it is difficult to meet discharge standards. High consumption of chemical materials and other problems, to achieve the effect of industrialized operation, simple structure, and reduce the pressure on environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

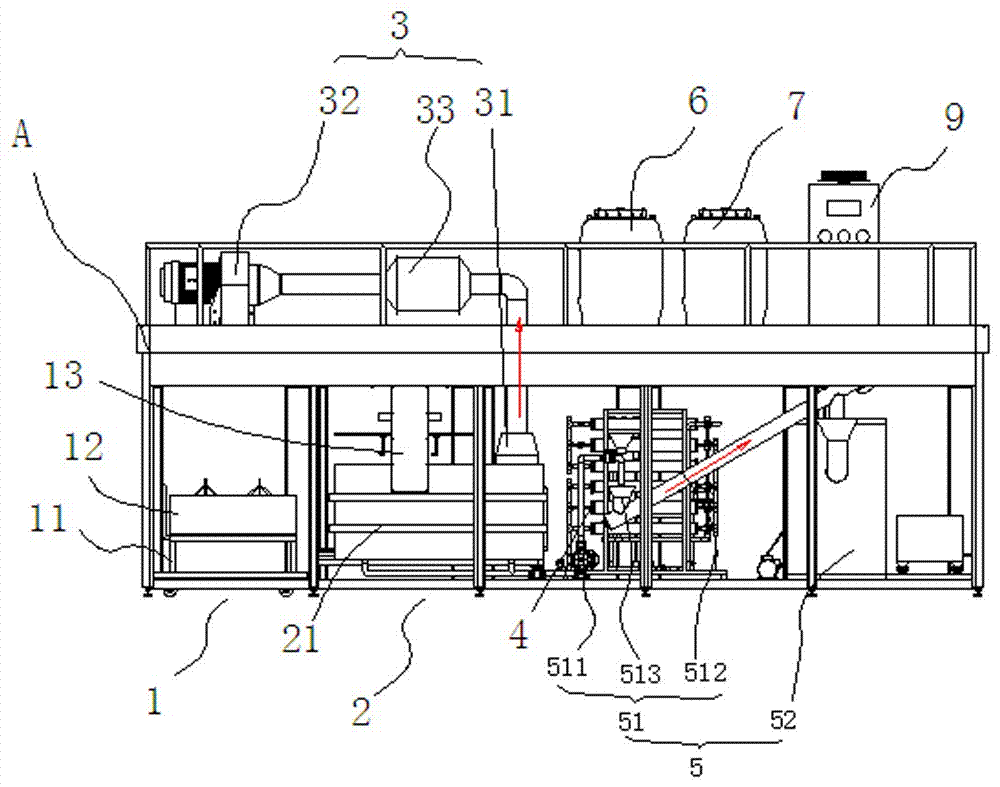

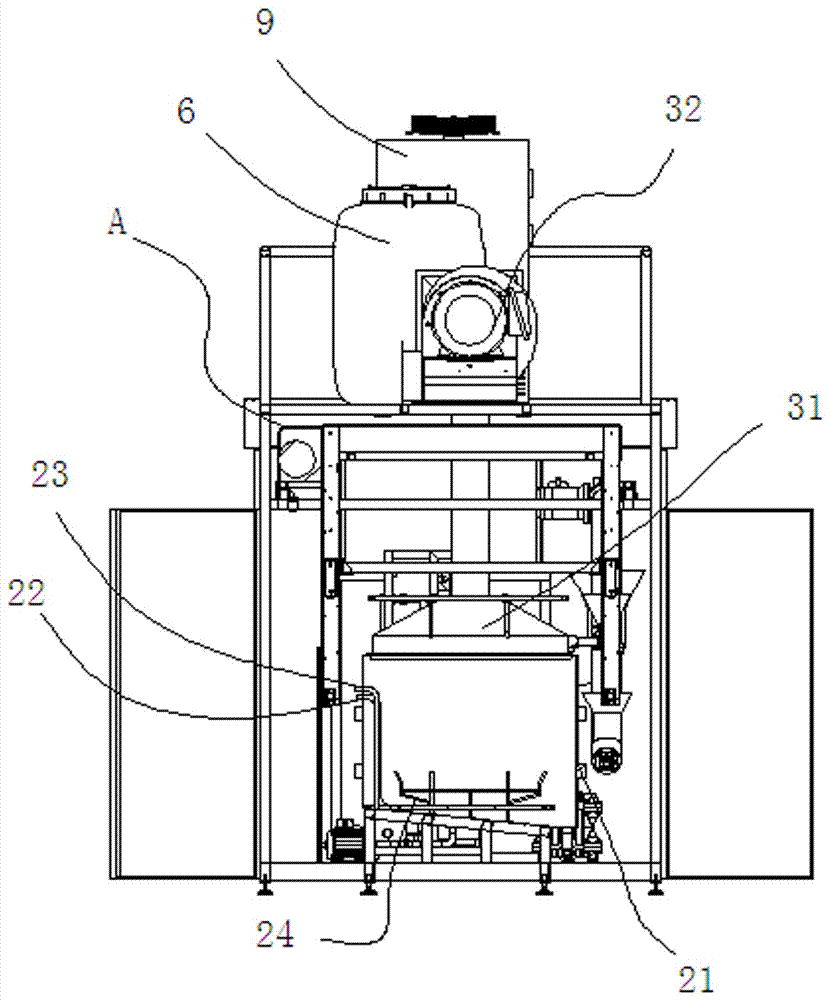

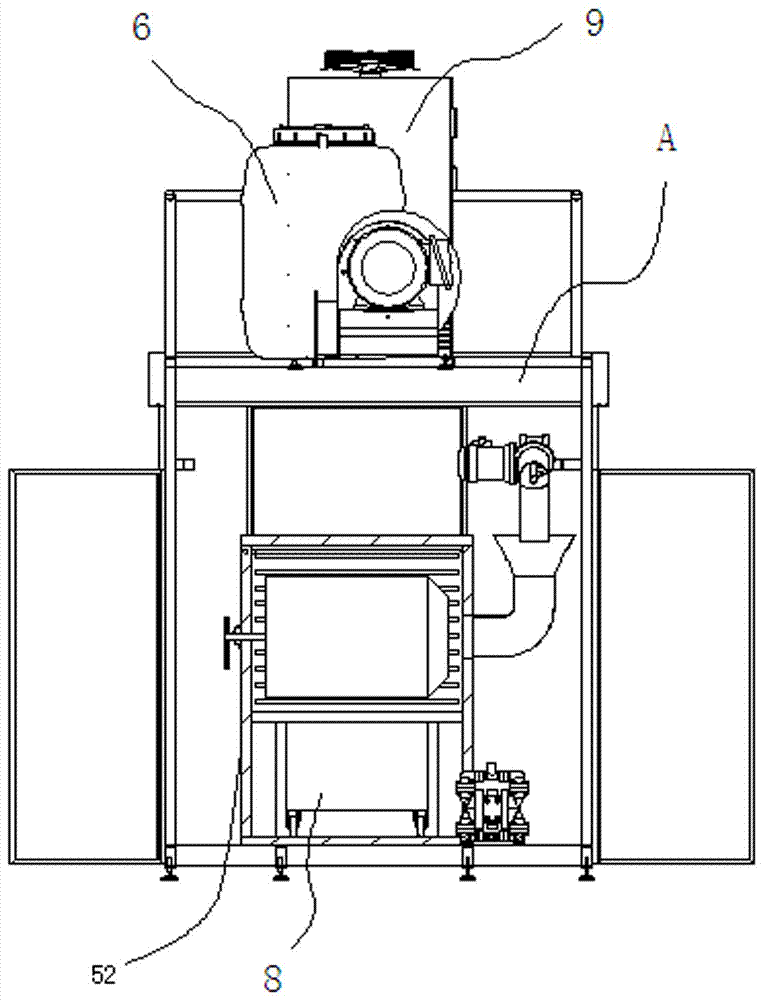

[0032] Example: see Figure 1 to Figure 5 As shown, a treatment equipment for nickel or phosphorus waste liquid, the equipment includes a feeding device 1, a waste liquid nickel treatment unit 2, a gaseous treatment unit 3, a liquid treatment unit 4 and a solid treatment unit 5. Feeding device 1, waste liquid nickel processing unit 2, gaseous state processing unit 3, liquid state processing unit 4 and solid state processing unit 5 are all installed on the double-layer frame body A, wherein feeding device 1, waste liquid nickel processing unit 2, liquid state The processing unit 4 and the solid processing unit 5 are located on the first floor, while the gaseous processing unit 3 protrudes to the second floor through the second floor.

[0033] see Figure 1 to Figure 5 As shown, the aforementioned feeding device 1 includes a feeding trolley 11, a hanging basket 12 and a manipulator 13; The lifting device on both sides of the unit 2, the hanging basket 12 has a hook; the manipu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com