Welding structure and method of multi-layer casing pipe structure

A multi-layer casing and welding structure technology, applied in welding equipment, electron beam welding equipment, tubular objects, etc., can solve the problems of low brazing strength, influence of base material performance, difficulty in meeting product use requirements, etc., to meet Welding requirements, meeting design requirements, optimizing the effect of welding sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

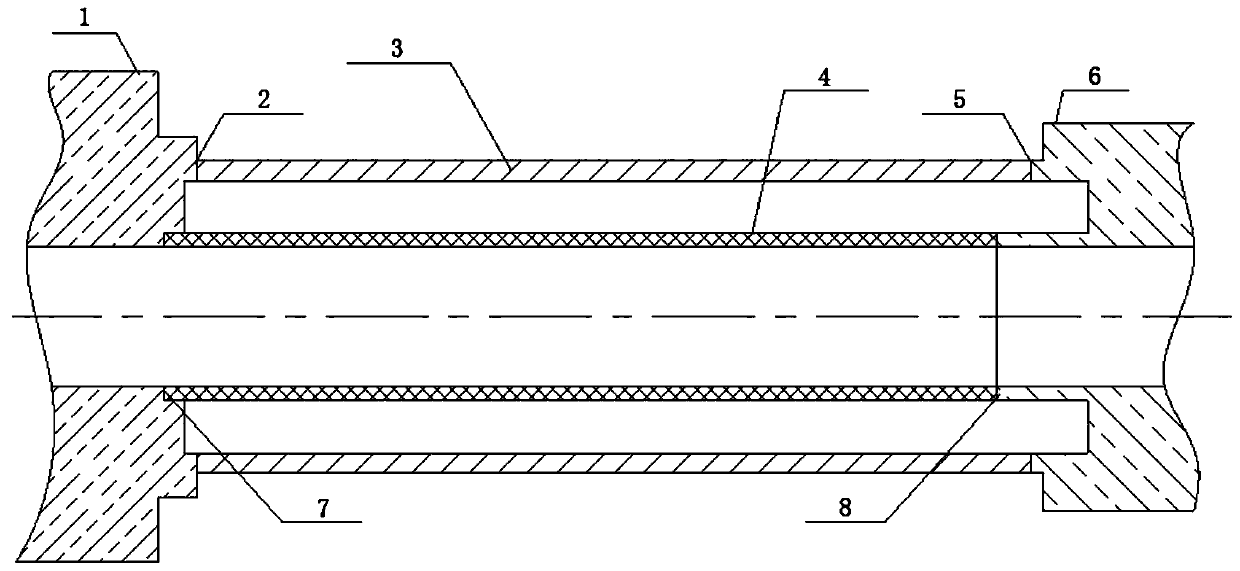

[0030] In this embodiment, a welding structure of a multi-layer sleeve structure is specifically provided, including a multi-layer sleeve. In fact, the multi-layer casing may also be three layers, four layers, etc., and the double-layer casing is used as an example to illustrate here.

[0031] It also includes positioning structural parts respectively located on both sides of the double-layer casing. The positioning structural parts are provided with welding grooves that match the casings of each layer. On the other hand, it can form a welding surface between the sleeves of each layer and the positioning structure, so as to cooperate with the electron beam welding equipment for welding. The welding grooves are concentrically arranged, and the ends of the sleeves of each layer are aligned with each welding groove and connected by welding. Since the welding grooves are concentrically arranged, the inner casing 4 After being assembled and positioned with the outer sleeve 3 accor...

Embodiment 2

[0035] Based on the welding structure of the multilayer casing structure provided in Embodiment 1, in this embodiment, a welding method for the multilayer casing structure is also disclosed, the method includes the following:

[0036] (1) The left positioning structural part 6 and the right positioning structural part 1 are respectively arranged on both sides of the multi-layer casing, and the welding slopes are respectively designed on the left positioning structural part 6 and the right positioning structural part 1 according to the structural characteristics of the multi-layer casing mouth size;

[0037] (2) Process a plurality of welding grooves that are concentrically arranged on each positioning structural member according to the welding groove size; since this method takes the welding structure of the layer casing structure in Embodiment 1 as an example, then the left positioning structural member 6. Process the first annular protrusion and the second annular protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com