Dot matrix type feeding machine and machine tool automatic feeding and discharging system comprising feeding machine

An automatic loading and unloading, dot-matrix technology, which is applied in the direction of manipulators, metal processing, chucks, etc., can solve the problems of high cost and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

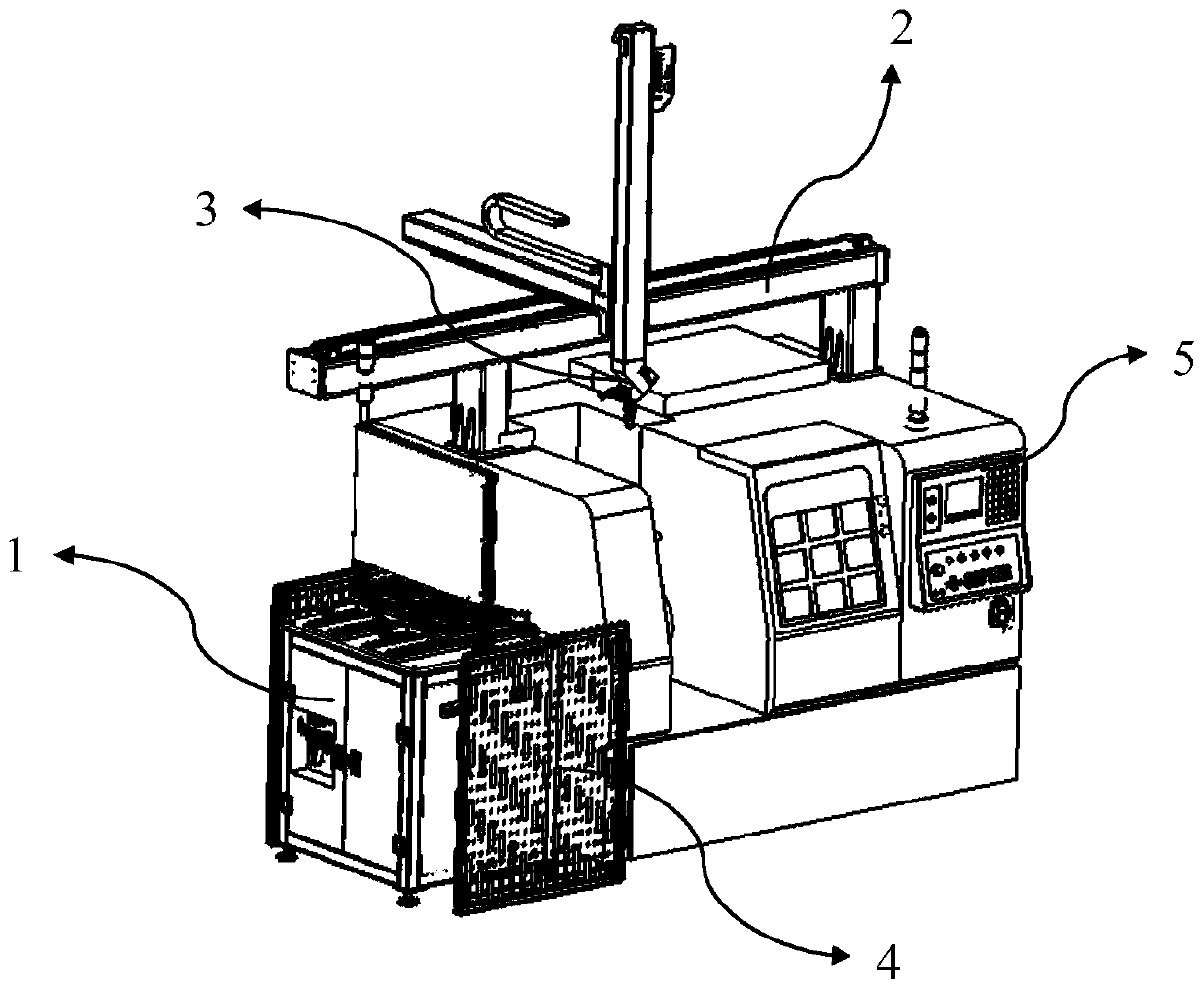

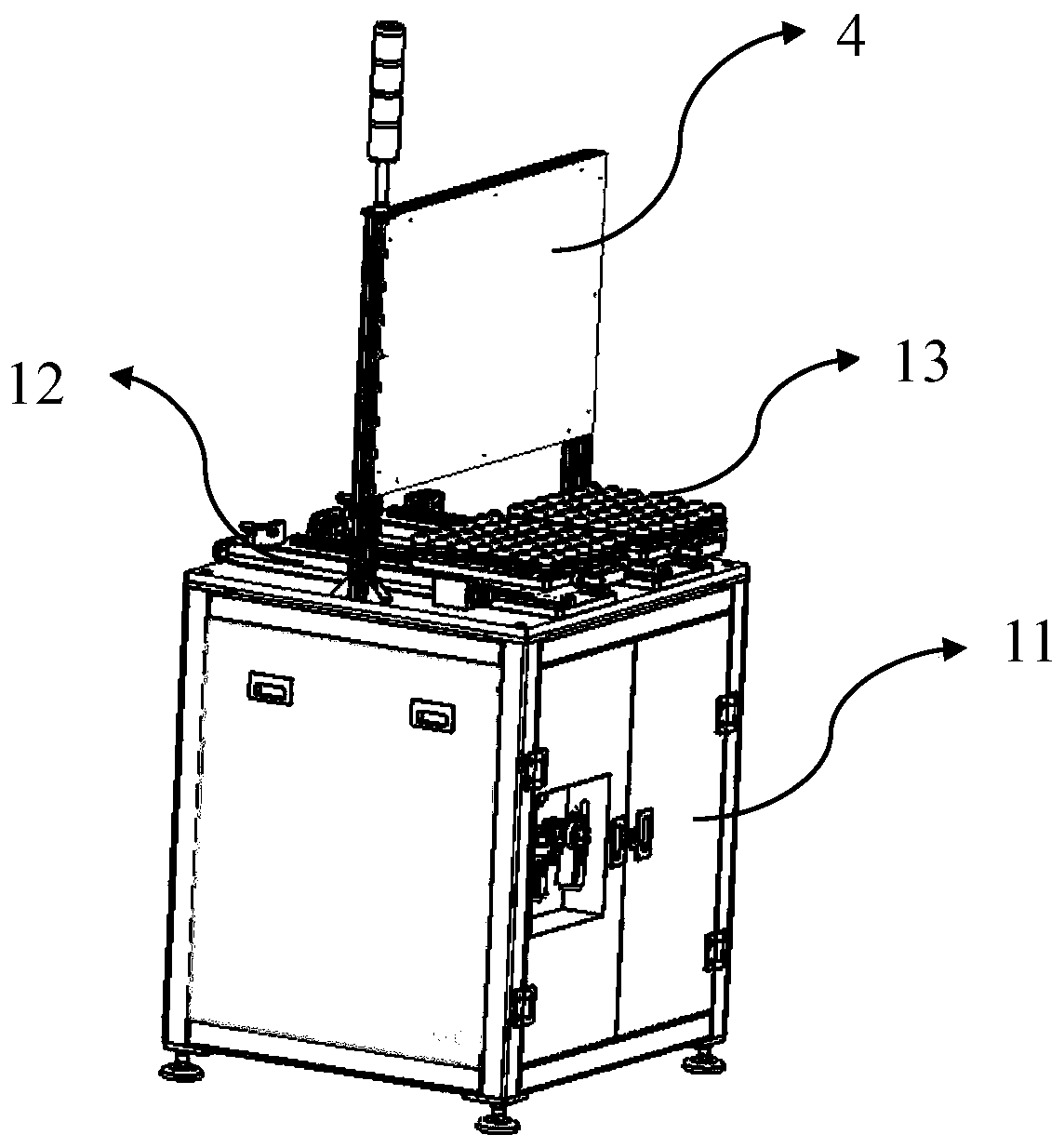

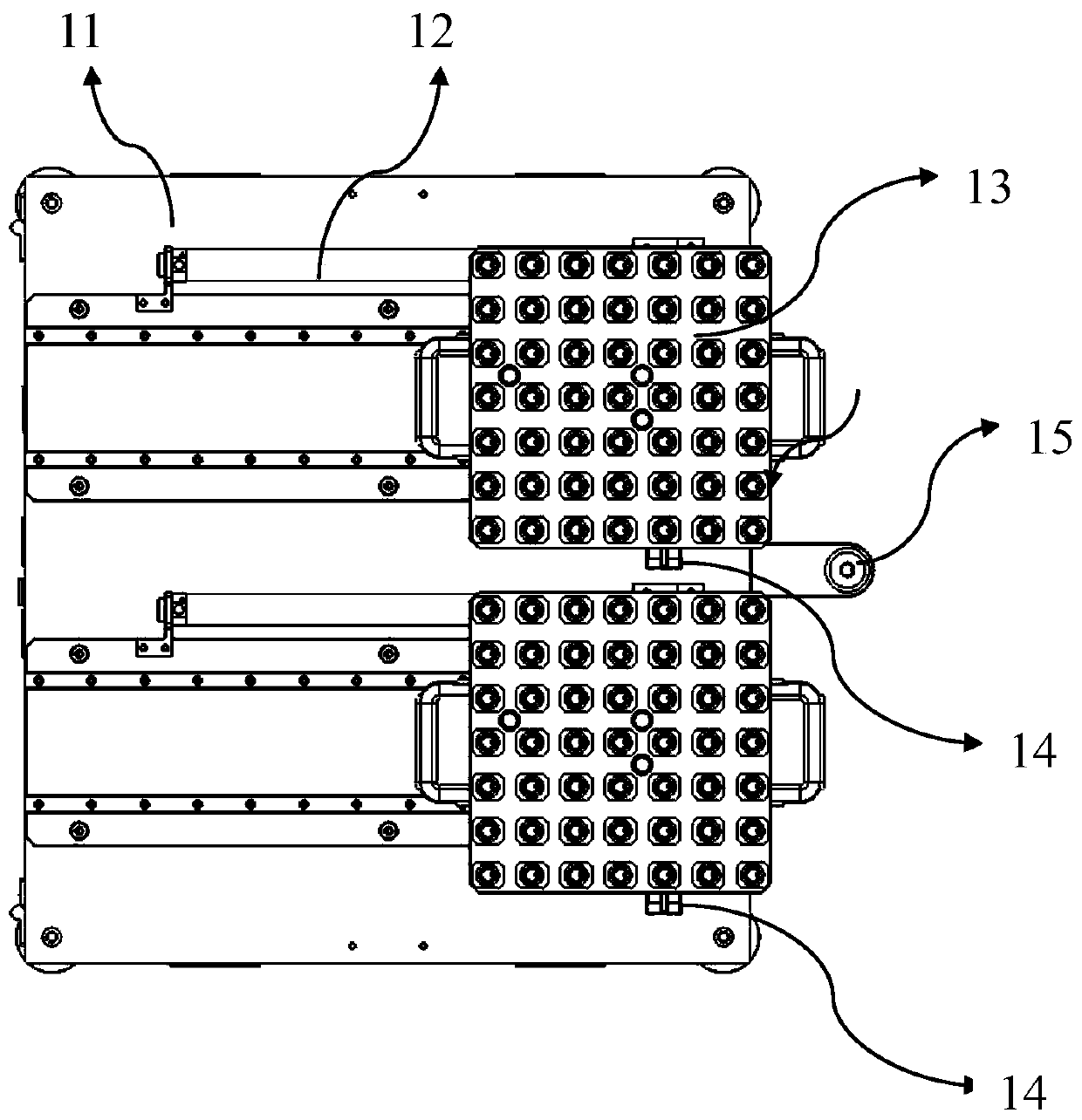

[0034] Such as figure 1 As shown, the present invention discloses a set of machine tool automatic loading and unloading system. The machine tool automatic loading and unloading system is mainly composed of a dot matrix feeder 1, a robot 2, a robot clamp 3, a control system and a protective fence 4; the robot clamp 3 It is arranged at the end of the arm of the robot 2; the robot 2 communicates with the dot-matrix feeder 1 and the machine tool 5 through the control system, and automatically realizes the following key steps:

[0035] 1) The robot 2 takes out the blanks 00 on the jig tray 13 one by one in a matrix manner;

[0036] 2) The robot 2 puts the blank 00 on the secondary positioning mechanism 15 for fine positioning;

[0037] 3) The robot 2 takes out the processed finished product 000 in the machine tool 5;

[0038] 4) The robot 2 puts the blank 00 on the chuck of the machine tool 5 or in the mold;

[0039] 5) Robot 2 puts the finished product 000 in the designated pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com