Dust removal equipment for wall top cutting

A technology of dust removal equipment and cutting discs, which is applied in stone processing equipment, liquid separation agent, and dispersed particle separation, etc., can solve the problems of ineffective dust reduction and difficult collection of waste water, and achieve the effect of easy cleaning and reduced dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

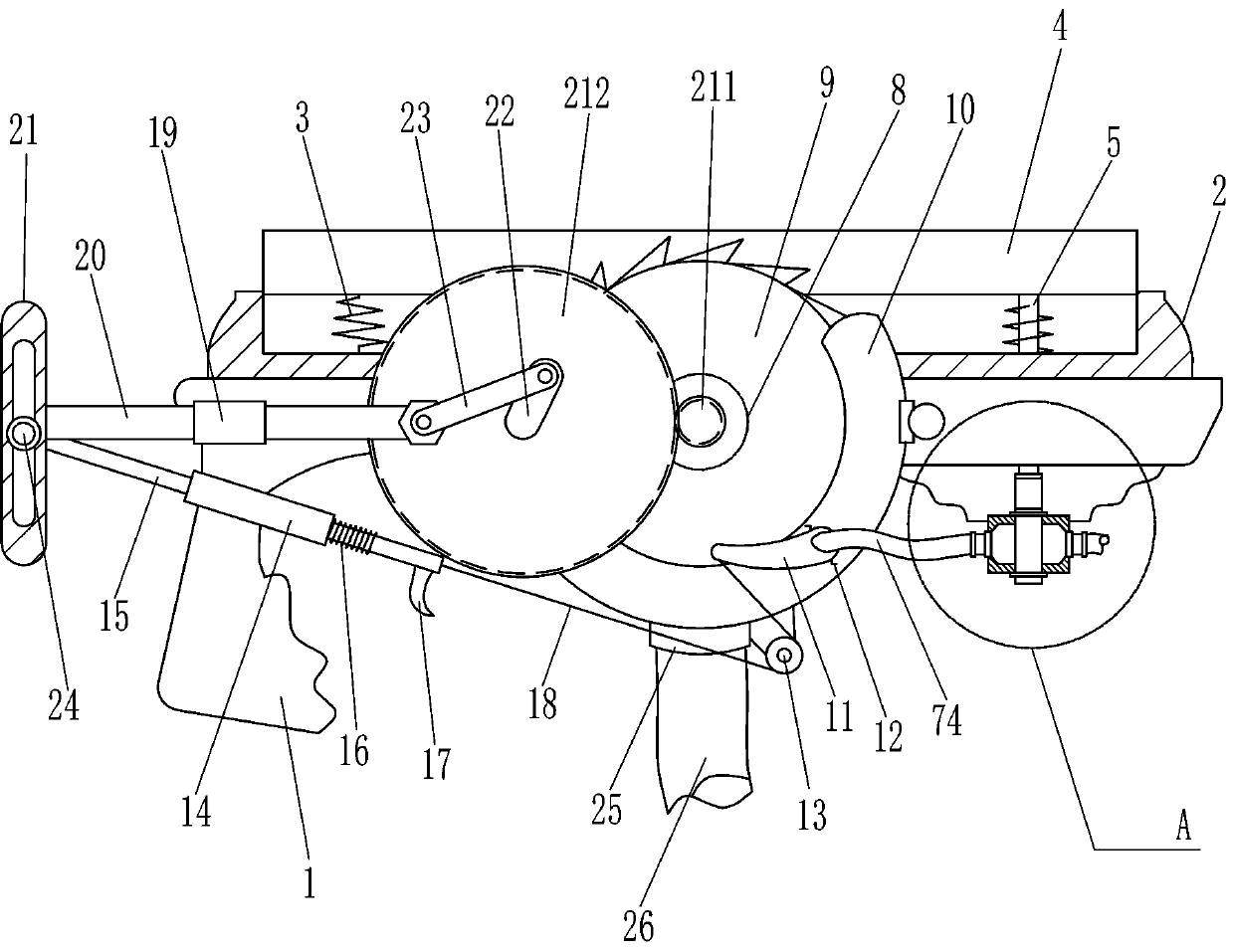

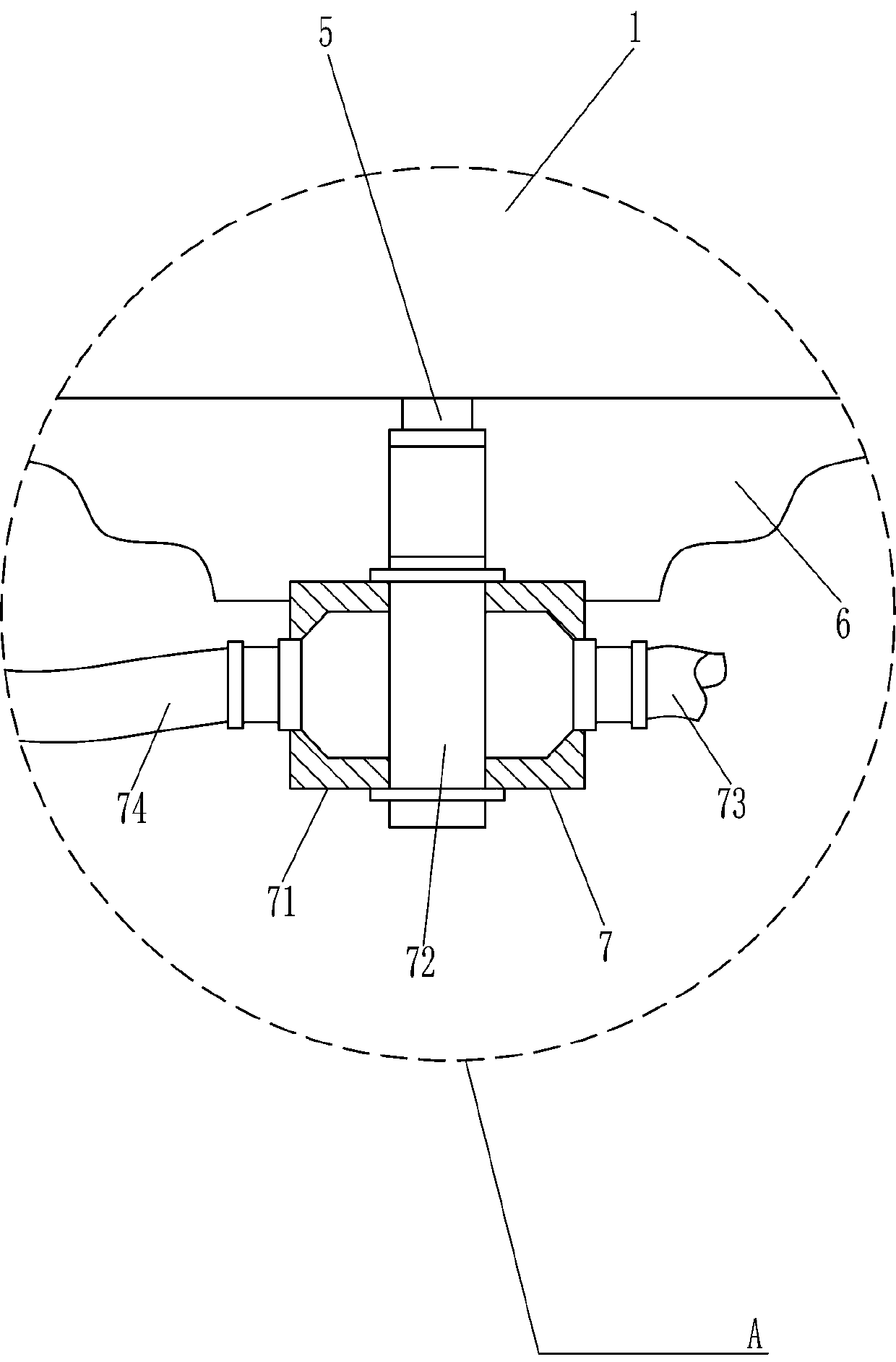

[0018] A dust removal equipment for wall top cutting, such as Figure 1-2 As shown, it includes grip plate 1, concave plate 2, first compression spring 3, transparent plate 4, moving rod 5, mounting plate 6, liquid inlet device 7, motor 8, cutting disc 9, safety cover 10, liquid spray Head 11, torsion spring 12, fixed pulley 13, first guide sleeve 14, first guide rod 15, second compression spring 16, push rod 17 and backguy 18, handle plate 1 top is provided with concave plate 2, concave plate 2. The left and right sides of the inner bottom are connected with the first compression spring 3, the top of the first compression spring 3 is provided with a transparent plate 4, and the right side of the bottom of the transparent plate 4 is connected with a moving rod 5, and the moving rod 5 is connected with the concave plate 2 and the grip in turn. The plate 1 is connected in a sliding manner, the bottom right side of the grip plate 1 is provided with a mounting plate 6, the front s...

Embodiment 2

[0022] On the basis of Example 1, such as figure 1 As shown, it also includes a second guide sleeve 19, a second guide rod 20, a guide sleeve 21, a first gear 211, a second gear 212, a first connecting rod 22, a second connecting rod 23 and a sliding sleeve 24, and the cutting disc 9 The front side is provided with a first gear 211, the left part of the safety cover 10 is rotatably connected with a second gear 212, the second gear 212 meshes with the first gear 211, and the left front side of the grip plate 1 is provided with a second guide sleeve 19, A second guide rod 20 is slidably connected in the second guide sleeve 19, and a guide sleeve 21 is provided at the left end of the second guide rod 20, and a sliding sleeve 24 is slidably connected in the guide sleeve 21. Connect, the right end of the second guide rod 20 is rotatably connected with the second connecting rod 23, the right end of the second connecting rod 23 is rotatably connected with the first connecting rod 22,...

Embodiment 3

[0025] On the basis of Example 2, such as figure 1 As shown, it also includes a filter cover 25 and a drain pipe 26. The bottom of the safety cover 10 is provided with a filter cover 25, and the filter cover 25 is connected with a drain pipe 26.

[0026] Through the cooperation of the filter cover 25 and the drain pipe 26, the waste water in the safety cover 10 can be filtered, and the sand particles are left in the filter cover 25 to facilitate subsequent cleaning and collection, and the waste water is discharged to the collection area through the drain pipe 26. It avoids the waste water from dripping directly on the ground, which makes subsequent cleaning inconvenient, and achieves the effect of easy cleaning.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap