Milk machine aseptic packaging bag and production process thereof

A technology for packaging bags and milk machines, applied in the field of packaging film materials, can solve the problems of broken bags and leakage, insufficient heat-sealing strength of packaging bags, and leakage of wear and tear, etc., and achieves lowering the heat-sealing temperature, improving the heat-sealing strength, and improving the flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

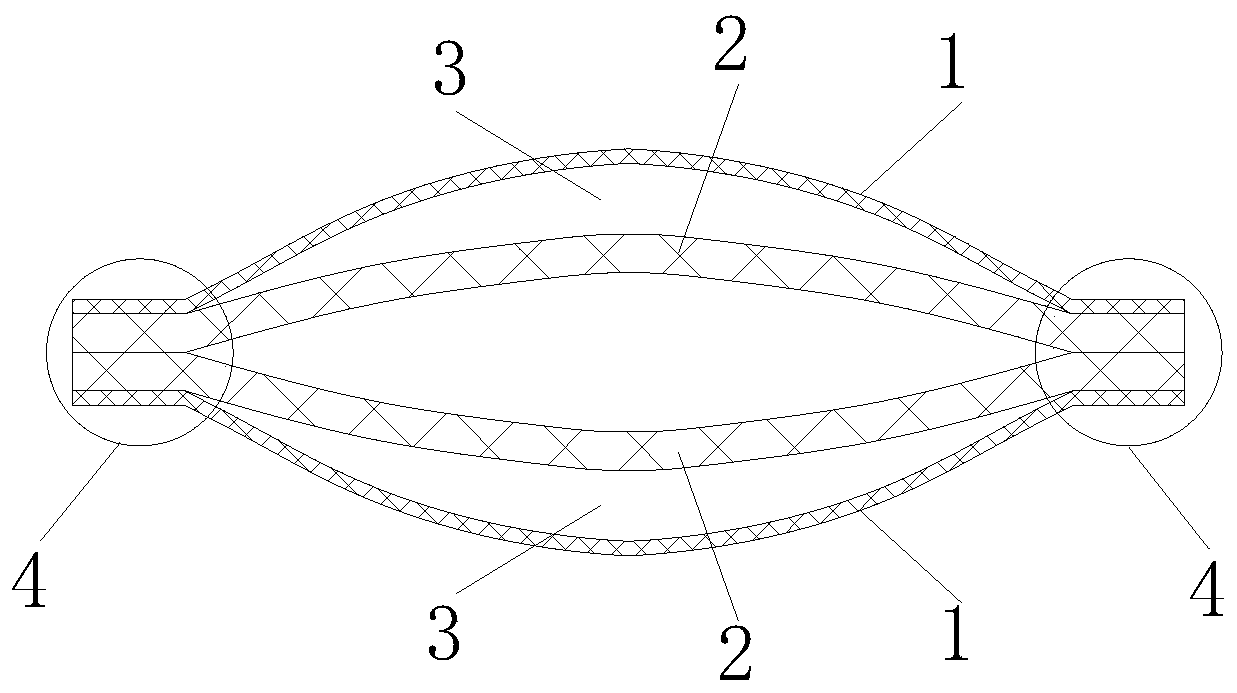

Image

Examples

Embodiment Construction

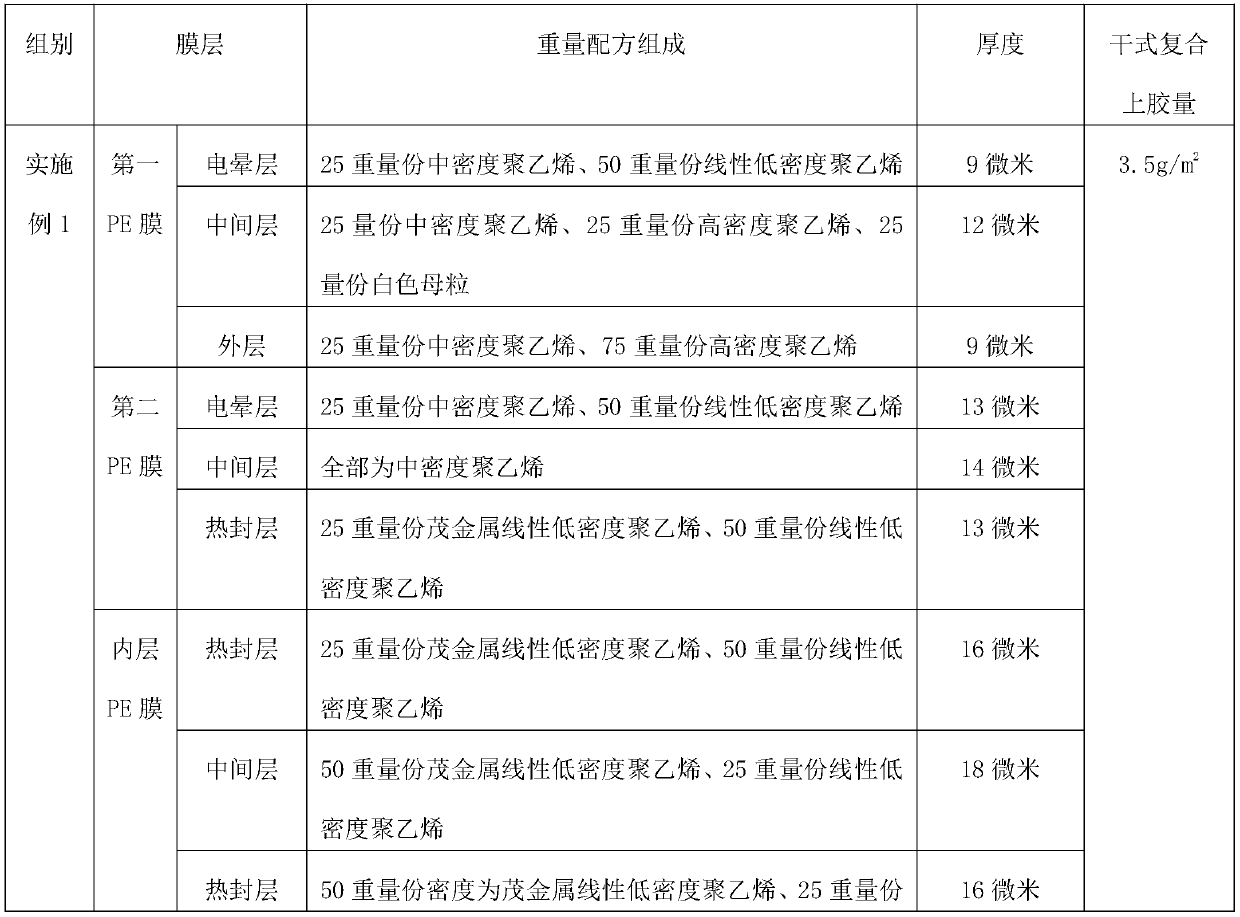

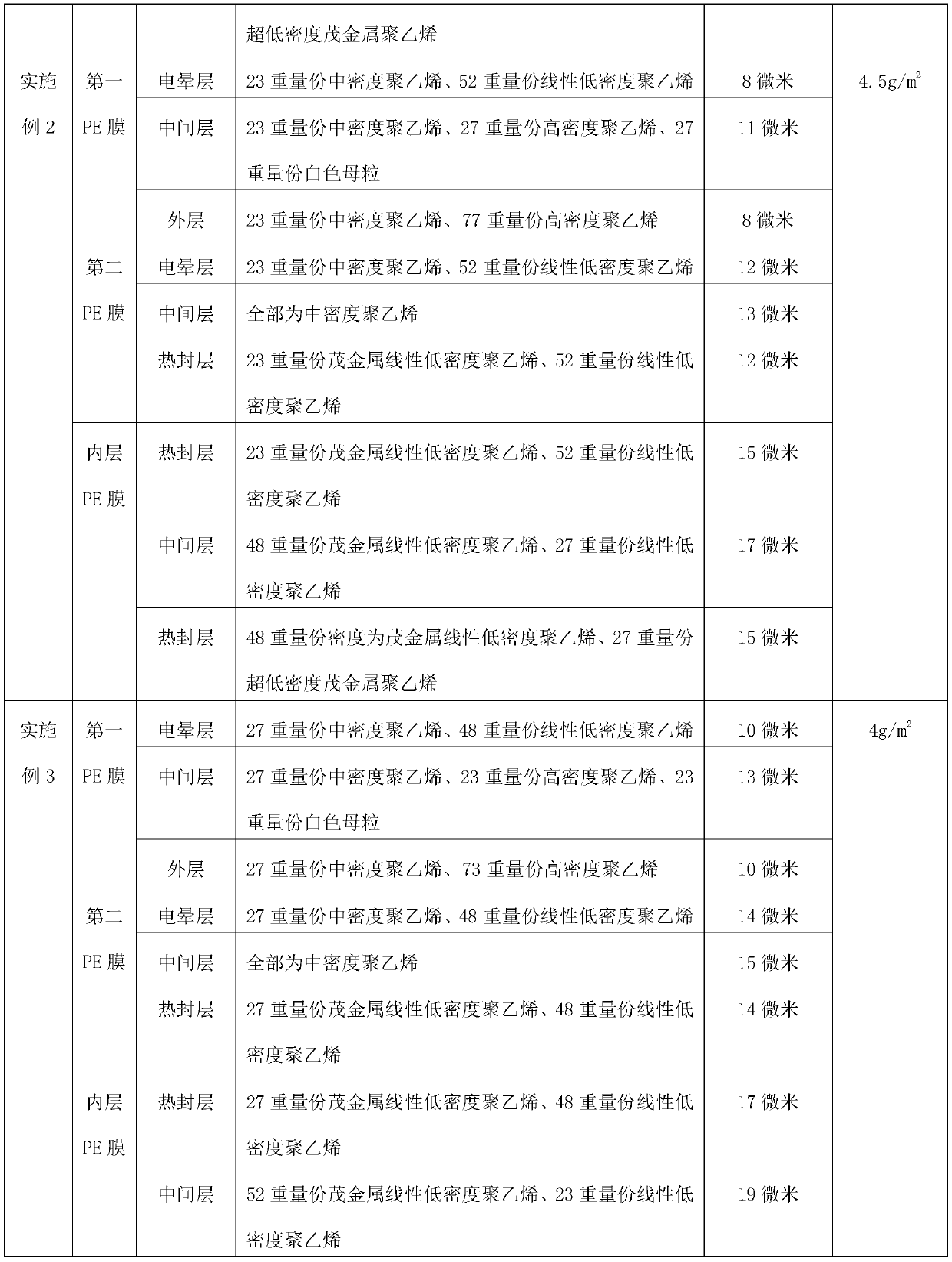

[0049] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

[0050] The source of raw materials used in the present invention is as shown in table 1 below:

[0051] Table 1

[0052] Resin name Resin grade manufacturer Melting point °C Melting finger g / 10min Density g / cm 3

medium density polyethylene 5538 Dow 129 1.3 0.941 Metallocene Linear Low Density Polyethylene 2010MA Exxon 114 1.0 0.920 High-density polyethylene F04660 Sabic 135 0.7 0.961 white masterbatch UF880 Mitsui Chemicals 127 1.8 0.937 Ultra Low Density Metallocene Polyethylene 1881 Dow 98 0.8 0.905 Linear Low Density Polyethylene 2045G Dow 119 1.0 0.920

[0053] In the following implementation of the present invention, each film layer formula is as shown in table 2 below:

[0054] Table 2

[0055]

[0056]

[0057]

[0058]Prepare milk machine as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com