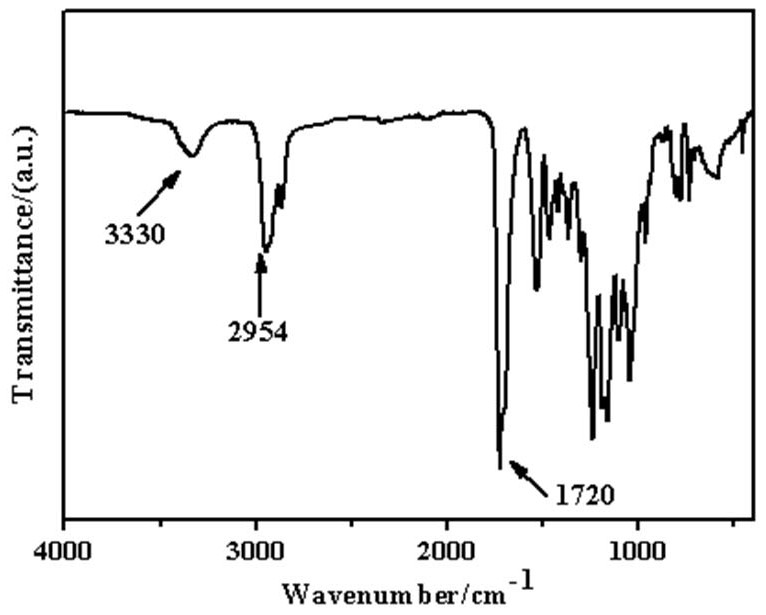

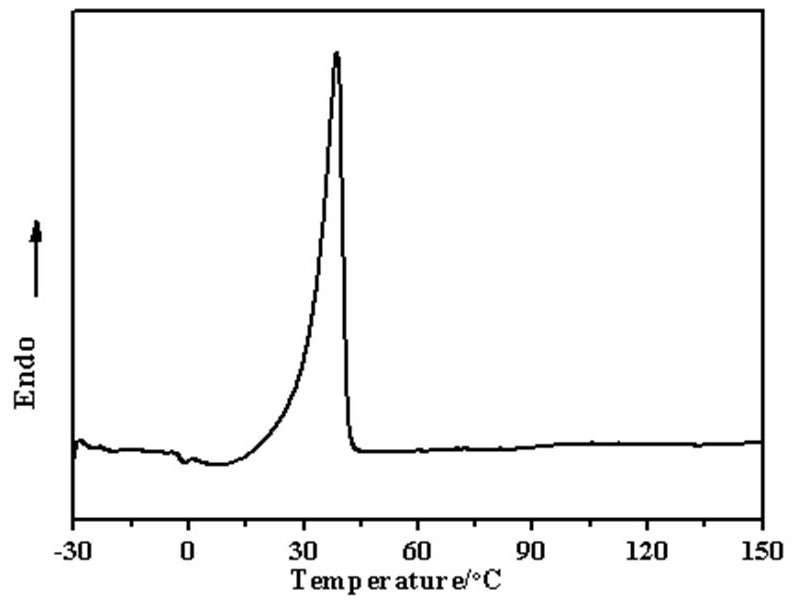

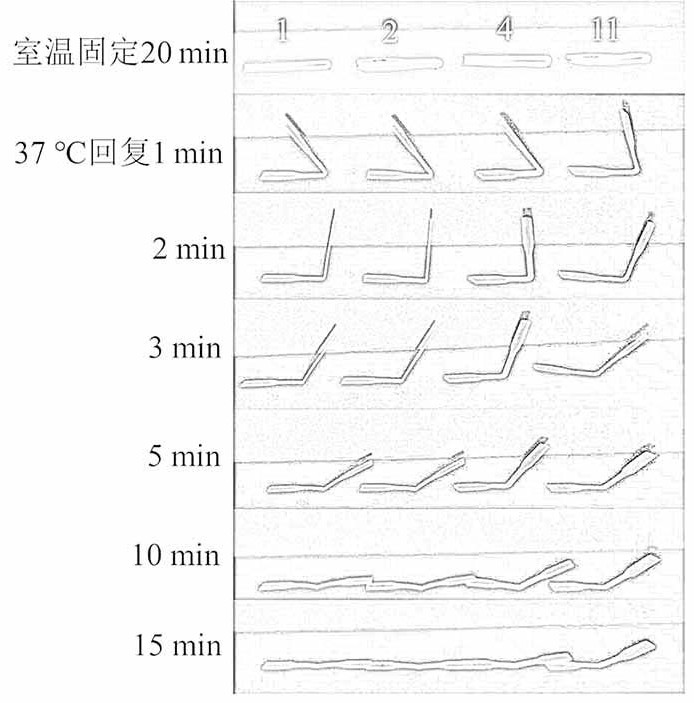

Body temperature responsive shape memory polyurethane material and preparation method thereof

A polyurethane material and shape-responsive technology, applied in the field of shape memory materials, can solve the problems of incompatibility between two phases, and achieve the effects of excellent environmental performance, good shape memory performance, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A body temperature responsive shape memory polyurethane material, using polyε-caprolactone diol with a relative molecular weight of 2000 as a soft segment, isophorone diisocyanate, hexamethylene diisocyanate and chain extender 1 , 4-butanediol is a hard segment, takes dibutyltin dilaurate as a catalyst and takes dimethyl carbonate as a green solvent to make, and the consumption grams and milliliters of each raw material are as follows: wherein polyε-caprolactone diol 23.1~29.3%, 10~15 g, hexamethylene diisocyanate 2.2~5.3%, 0.9~2.6 ml, isophorone diisocyanate 6.2~10.5%, 2.5~5.1 ml, 1,4-butane Diol is 3.5~4.6%, 1.5~2.3 ml, dibutyltin dilaurate is 0.10~0.12%, 0.05 ml, the first addition amount of dimethyl carbonate is 20.8~24.9%, 10~15 ml, dimethyl carbonate The second addition amount of ester is 31.2-37.4%, 10-15 ml.

[0025] A preparation method of a body temperature responsive shape memory polyurethane material, the body temperature responsive shape memory ...

Embodiment 2

[0033] Example 2: Prepare body temperature responsive shape memory polyurethane material according to the following steps:

[0034] Step 1), put 10 g of polycaprolactone diol dried by rotary evaporation into a three-necked flask with nitrogen gas, oil bath at 60°C, and electric stirring for 1 hour to completely melt the polycaprolactone diol;

[0035] Step 2), after fully melting the polycaprolactone diol, the temperature is lowered to room temperature, 1.0 ml of hexamethylene diisocyanate is added, the temperature is gradually raised to 60°C, and the electric stirring is carried out to fully react for 3 hours;

[0036] Step 3), add 3.6 ml of isophorone diisocyanate, add 10 ml of solvent dimethyl carbonate, stir electrically for 30 minutes;

[0037] Step 4), adding 0.05 ml of catalyst dibutyltin dilaurate, and fully reacting for 1 hour to obtain a prepolymer;

[0038] Step 5), add 1.5 ml of 1,4-butanediol, carry out chain extension reaction, fully react for 4 hours to the end...

Embodiment 3

[0041] Example 3: Prepare body temperature responsive shape memory polyurethane material according to the following steps:

[0042] Step 1), put 12 g of polycaprolactone diol dried by rotary evaporation into a three-necked flask filled with nitrogen, oil bath at 60°C, and electric stirring for 1 hour to completely melt the polycaprolactone diol;

[0043] Step 2), after fully melting the polycaprolactone diol, drop to room temperature, add 1.3 ml of hexamethylene diisocyanate, gradually heat up to 60°C, stir with electric power, and fully react for 3 hours;

[0044] Step 3), add 4.2 ml of isophorone diisocyanate, add 10 ml of solvent dimethyl carbonate, stir electrically for 30 minutes;

[0045] Step 4), adding 0.05 ml of catalyst dibutyltin dilaurate, and fully reacting for 1 hour to obtain a prepolymer;

[0046] Step 5), add 1.8 ml of 1,4-butanediol, carry out chain extension reaction, fully react for 4 hours to the end of the reaction, add 15 ml of solvent dimethyl carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com