Polyimide material and solvent-free preparation method and application thereof

A polyimide and reactor technology, applied in the field of polymer preparation, can solve the problems of difficulty in cleaning, adverse effects on the electrochemical performance of batteries, generation of recovery costs, etc., so as to reduce production costs, reduce the use of solvents, avoid residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

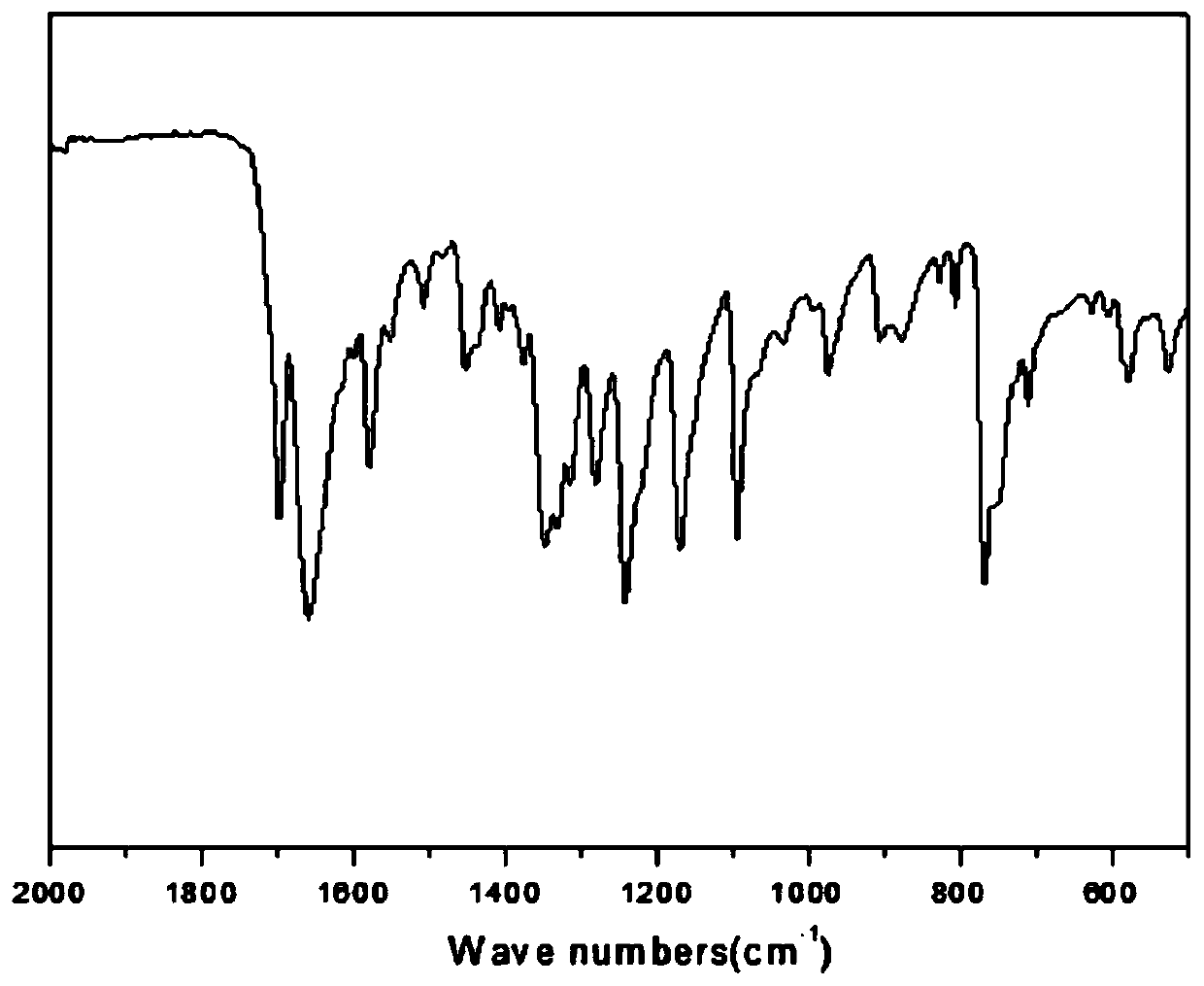

[0100] The preparation of embodiment 1 polyimide

[0101] Step A: Add the reactants 1,4,5,8-naphthalene tetracarboxylic dianhydride and ethylenediamine into the reactor at a molar ratio of 1:1, and the reaction vessel is a glass flask. The reactant was kept at 90° C. for 2 hours under the protection of argon, then raised to 150° C., and reacted at this temperature for 4 hours.

[0102] Step B: collect the product in step A, and keep it at 200° C. under vacuum for 24 hours to obtain a dry powder, which is designated as polyimide sample 1.

Embodiment 2

[0104] It is basically the same as Example 1, except that in the fixed bed reactor, the reactant is directly heated to 150° C., and reacted at this temperature for 10 hours, and the obtained product is recorded as polyimide sample 2.

Embodiment 3

[0106] It is basically the same as in Example 1, except that 1,4,5,8-naphthalene tetracarboxylic dianhydride is replaced by 1,2,4,5-cyclohexanetetracarboxylic dianhydride, and the obtained product is marked as polyimide sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com